Icing On The Cake

By Jesse Rotman

Advances in technology allow wholesale bakeries to create elegant cakes and masterful desserts that look like they were expertly designed by the bakery next door.

Who doesn’t love lip-smacking icing decorations on an already enticing product? Icing-depositor firms are using every move in the playbook to attract baked goods companies as customers and whet the appetite of consumers everywhere with fanciful finishing touches to doughnuts, pies, cookies, cupcakes, cinnamon rolls, breads and muffins.

No matter how good these baked products taste, it’s often the icing or glaze that enhances the product’s appearance, catches a consumer’s eye and leads to an impulse sale.

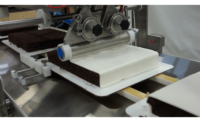

Icing equipment generally follows two styles. The traditional waterfall approach uses a modular-style enrobing machine or a spraying system that is generally involved in high-volume operations.

Waterfall systems are versatile in their applications, as well as easy to operate and clean.

Meanwhile, spraying technology generally covers the whole surface of product pans and/or creates stripes, spots or other decorations.

With icing systems today, the buzz is about how to apply it better and faster with less waste and at a lower cost. Here are some of the innovations in equipment from some of the nation’s leading suppliers:

Two Icing Systems

Bakon offers two types of icing systems: the traditional waterfall approach with a modular-style enrobing machine and the spraying system to cover the whole surface of products or create stripes or spots. For the waterfall approach, company engineers have designed a machine that is easy to operate and to clean. The system can handle everything from fondant and icing to chocolate, glaze and even butter. The spraying technology offers other benefits such as the possibility to ensure a perfect coverage with a very thin layer of products. The system is designed for high-volume operations, allows re-using any overspray and prevents any clogging of the spray heads, even when the machine is not spraying.

Bakon USA

Van Nuys, Calif.

1800-TRY-BAKON

Flexible Icing for Cupcakes

Colborne Corp. recently introduced a cupcake depositor for a variety of icing applications. This new design is capable of applying “single shot” split color icing to 12 and 24 mini-cupcake trays (variable size/shapes including a round party-pack configuration) at up to 480 per minute. In addition, it can deposit on six and 12 regular cupcakes in a 2x3 and 3x4 clamshell at more than 312 per minute. Custom manifolds for infinite icing variations are available to suit most customer applications.

Colborne Corp.

Lake Forest, Ill.

1- 847-371-0101

Servo-Driven System

Hinds-Bock has developed a new servo-driven icing depositor that’s ideal for accurate spreading of icings, creams, custards, fruit fillings and mousse. The entire depositor dives for bottom-up depositing via servomotor. This motor, tuning the spreading of product to minimize or eliminate extra down-stream hand dressing, drives metering pistons. Operator interface/PLC control is recipe-driven for easy setup. Tool-free tilting of the hopper and spout plate enables quick and easy disassembly and cleaning.

Hinds-Bock Corp.

Redmond, Wash.

1-877-292-5715

String Icing Applications

KESS Industries offers a system that strings of heated icing to doughnut products, cakes, bars, breads and other bakery goods. The fully automatic system creates eye-catching designs. The string-icer manifold can operate in a stationary position to create straight lines or oscillate back-and-forth to create patterns. The pump and conveyors’ speeds are adjustable by Variable Frequency Drives to quickly accommodate product and process changes. The icing section is constructed of urethane belting with UHMW scrapers, resulting in a clean belt that virtually eliminates bottom-side contamination.

KESS Industries

Auburn, Wash.

1-800-578-5564

Better Baking Solutions

Fedco, a division of The Peerless Group, provides system capabilities for cake, muffin and icing production, from mixing through final product cooling. Its icing machines can handle strips, strings, special patterns or placement, or full coverage on all types of biscuits and cookies. The company offer complete icing systems that can include continuous mixers/aerators, slurry mixers, holding tanks, transfer conveyors and cooling tunnels, as well as integrated system control packages.

Fedco, a division of The Peerless Group

Sidney, Ohio1-937-492-4158www.thepeerlessgroup.us

Piston Power in Baking

Unifiller Systems offers a range of volumetric piston depositors, which are known for their “user-friendly” designs. They have fewer parts and can be disassembled in less than 30 seconds without the use of tools. The company’s Universal depositor is equipped for clean depositing of standard or low-carb products such as muffins, cake batter, fruit pie fillings, and more. The power-lift frame lowers the base to floor level for easy manual filling. The Universal can be fitted with a wide variety of attachments, including hand guns, depositing heads, and nozzles for almost all bakery depositing applications.Unifiller Systems, Inc.

IBIE Hotel Space Going Quickly

Hotel rooms for the 2007 International Baking Industry Exposition are going quickly, with many of the choice rooms for the upcoming show already blocked out, according to the event’s organizers.

Attendees from across the globe are expected to attend this year’s IBIE, which runs Oct. 7-10 in Orlando. At the 2004 Bakery Expo, about 800 companies exhibited and around 20,000 food industry members visited the show.

The IBIE committee and its marketing firm, San Diego-based Marketing Design Group (MDG), launched its direct mail campaign last month to boost attendance for the show, which runs every three years.

Kimberly Hardcastle-Geddes, MDG account strategist, notes that IBIE organizers plan to rely on everything from e-mail blasts and advertising to the wooing of the international press to attract everyone from cookie and cracker producers to baked snack manufacturers.

Hardcastle-Geddes encourages IBIE exhibitors to develop their own integrated marketing campaign that urge potential customers to attend the show and visit their booths. Visit www.IBIE2007.com, or go to www.snackandbakery.com to read more about the show and link up with the IBIE Web site.