Commercial bakery equipment manufacturers continue to introduce new and redesigned mixing systems that address the specific and changing needs of commercial bakers, including flexibility, dough uniformity, easy sanitation and durability.

“Customers are moving toward more flexible production with high-quality products, while trying to reduce costs,” says Patricia Kennedy, president of WP Kemper Bakery Systems Ltd., Shelton, Conn., a North American subsidiary of WP BakeryGroup, Rietberg, Germany.

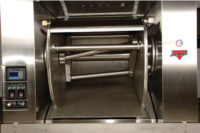

The company’s Titan mixer helps customers achieve these goals by offering an unsealed mixing bowl design that doesn’t compromise dough quality. The Titan allows the mix and oxygen to interact while still upholding the industrial process. Batch mixing also enables customers to change products from mix to mix.

Available as a single or double spiral unit, the Titan mixer features the Kemper three-zone mixing principle and handles wheat, mixed-wheat, rye and mixed-rye dough. In addition, the unit continuously monitors the temperature of its bearings, motors and hydraulic systems; automatically lubricates itself; and is available in a washdown model for greater sanitation, an increasingly important issue for bakeries.

Sanitation is also a key component in the new sanitary ribbon blenders and dual-shaft mixers recently introduced by Charles Ross & Son Co., Hauppauge, N.Y. According to sales manager Bill Alhofen, the units were introduced for customers who require a high degree of sanitation as well as complete mixing and discharge.

The ribbon blender features a discharge extruder at its trough, which enhances mixing, eliminates dead spaces and enables complete discharge of the finished product at a controlled rate.

The dual-shaft mixer processes viscous foods, such as sauces, peanut butter, hummus and syrups. Equipped with a high-speed disperser and a two-wing anchor, the mixer is designed for pureeing solid ingredients, blending minor components into thick batches, dispersing agglomerates, maintaining an even batch temperature and producing a smooth, uniform end product. Its change-can design (meaning it can be used with multiple, interchangeable mix vessels) allows it to be used with a platen-style discharge system for fast and easy material transfer.

Stephen Bloom, vice president of Allied Bakery Equipment Co. Inc., Santa Fe Springs, Calif., the North American importer, distributor and manufacturer’s representative for Sancassiano vertical mixing technologies, also cites sanitation as an important issue for wholesale bakers. “There’s a demand for easier sanitation and higher standards of sanitation,” Bloom says.

He adds, however, that more bakers also are seeking mixing technologies that can be scaled up or modified as needed. “One of the features of [Sancassiano’s Genesi series of mixers] is that a single mixer can, at a later date, without significant headache or changes, be incorporated into an [existing Sancassiano] automated system,” he explains.

This includes Sancassiano’s newest mixing technology, the Revo, which was developed specifically for cookies. The elevated, self-supporting unit features a patented, removable, flat-bottom bowl; a large choice of mixing tools designed for specific dough types; and scrapers that scrape the bowl’s bottom and sides. The unit gently mixes dough with minimal energy input, reads and monitors dough temperatures and automatically feeds difficult ingredients. Available in partial or full stainless steel versions, the Revo can be washed down.

Dough uniformity is another concern for today’s bakers. “There’s a lot of interest in continuous mixing right now because a lot of older systems—and even some new ones—are presenting dough in batch-based mixes that isn’t uniform, even within a single batch,” explains Ed Fay, president of CMC America Corp., Joilet, Ill. “That’s a problem that has to be eliminated.”

CMC America recently began offering its industrial horizontal dough mixers—with roller bar agitators, single sigma agitators and double sigma agitators—with a new, patented tilt bowl and cooling jacket designed to improve the mixing process, offer efficiency enhancements and energy, labor and sanitation savings. Fay expects the new technology to deliver the biggest benefits in applications for roller bar dough mixers processing yeast-raised dough.

The new machines allow mixing beyond the standard 3.5 to 4 yeast-raised dough batches per hour. “CMC’s designs allow us to go well beyond this [output] in pursuit of as many as five, six or seven year-raised batches per hour, depending on formulation,” says Fay. “The CMC platform is capable of offering smaller, faster batches of a highly uniform character, so that more reliable product is sent down the line for processing.”

Buying considerations

Like other commercial bakery equipment manufacturers, mixing system manufacturers typically solicit input from their customers when designing new machinery, enabling them to offer bakeries systems that best suit their customers’ needs. This puts them in the perfect position to offer some additional factors bakeries should think about before finalizing their purchase.

“Mixing is an art,” says Alhofen. “The outcome that you can expect from a certain type of mixing equipment can vary extensively, depending on the application. Often, there is no all-purpose, off-the-shelf solution. Some level of customization is beneficial, if not necessary.

“The bulk density of your powders, the shear-thinning quality of your solution, the friability of one component, changes in viscosity throughout the mixing cycle or the heat-sensitivity of your final product—all of these and many other factors that may be unique to your formulation should be taken into consideration when selecting the right type of mixer and the right features that your process needs.”

David McCarthy, president and CEO of TriCore Inc., a Racine, Wis.-based systems integrator, says that “a major issue that can’t be overlooked is the need to properly integrate a new mixer with the rest of the equipment in the plant, which includes the management of upstream and downstream information that influences the performance of the new mixing system and the plant itself. Doing otherwise can lead to problems that range from manual and inefficient practices to poor product consistency, which is often why new mixers are installed in the first place. The key is to ensure new mixing equipment is in sync with the rest of the plant and the processes involved, not the other way around.”

Allied Bakery Equipment’s Bloom, meanwhile, advises that bakeries look beyond price and consider the long-term advantages in product quality and market position that they can gain when choosing one type of mixer over another.

The construction quality of the system should be top of mind, too. “Downtime is much more costly than the initial capital outlay to buy a better piece of equipment,” Bloom says.

CMC America’s Fay, on the other hand, thinks that long-term operating costs are probably more important considerations than actual capital costs. “After return on investment and payback is achieved, what is a baker stuck with forever?” he asks. These costs typically include labor, utilities, maintenance, changeover, flexibility (or lack thereof), sanitation and cleaning.

“Sanitation costs are an ever more critical part of the major food industry requirements,” Fay explains. “The increase in [Food and Drug Administration] evaluation and sanitary requirements reflect directly on the cleanability of the equipment. Methods of cleanability and the amount of labor required to achieve these heightened sanitary conditions are a long-term operating cost that engineers often overlook.”

Which brings Fay to another consideration often overlooked by many major bakeries and food processors when purchasing equipment. “At a lot of companies, the engineers decide [what they’re going to buy],” he says. Once the engineers install the equipment, the operations department is charged with maintaining a machine that may take longer to clean, requires more maintenance and has a lot of unexpected downtime. Bringing everyone involved in the selection, use and maintenance of a mixing system together at the onset could reduce problems down the road.

As federal regulations, consumer demand and a host of other changing variables continue to impact wholesale bakeries, mixing system manufacturers will continue to develop new and refine existing equipment that meets their customers’ needs—be for a single mixer or a entire system.