The Centers for Disease Control and Prevention (CDC) released a report in February that reconfirms what most adults already know: A majority of Americans consume too much sodium. Too much sodium can increase the risk of high blood pressure, which often leads to heart disease and strokes. Processed and restaurant-prepared foods contain the most sodium of the foods people eat.

Among the 10 foods that the CDC cites as those accounting for more than 40% of the sodium people eat are breads and rolls, pizza and snacks (chips, pretzels and popcorn). Surprisingly, breads and rolls topped the list, not because they contain extremely high levels of sodium, but because Americans consume a lot of these baked goods.

The continuous generation of new dietary information from the CDC, the U.S. Department of Agriculture (USDA) and other health organizations is permitting consumers to scrutinize the labels more of products they buy. They are also looking beyond how many calories they have. They’re now also focusing on what these products don’t contain, such as artificial ingredients and high levels of sugar and salt.

Ingredient makers are taking note of consumers’ changing demands, too, and are developing products that will enable their customers to create tasty, better-for-you foods. For bakers and snack manufacturers, this means new and reformulated ingredients that will enable them to create products with less salt, but more flavor.

For instance, in February, Caravan Ingredients, Lenexa, Kan., introduced a low-sodium version of a baking staple—baking powder—-as a replacement for regular, double-acting baking powders containing sodium acid pyrophosphates. The Low Sodium Baking Powder uses a non-sodium aluminum phosphate-based leavening system to reduce sodium by as much as 44% versus conventional baking powders, according to the company, while releasing the proper amounts of leavening gas at the various stages of mixing to facilitate batter scaling and depositing.

“The acids are processed differently to provide a more thorough reaction,” says Caravan’s bakery applications manager Eric Spelger. “This provides a cleaner, finished flavor profile and, in most cases, the reduction of sodium brings out the sweetness perception of finished baked goods.”

Getting physical

Ingredient manufacturers are also taking physical attributes such as size and shape into consideration when developing low-sodium products.

Omaha, Neb.-based Spicetec Flavors & Seasonings, a ConAgra Foods brand, introduced Micron Salt last year, a patented product with smaller particles than traditional granulated or flour salt. “[It] has three times more surface area per volume than traditional salt and flavors without the added sodium that comes with larger salt particles,” says principal development scientist Meredith Bishop, who adds that Micron Salt also has a different flavor release when it dissolves on the tongue.

Micron Salt can be used in topical snack seasonings and topical applications on flatbreads, breads and crackers. According to Bishop, it’s also ideal for use in oil slurries, snacks and other topical applications where its fine texture and low density keep it dispersed.

In addition to meeting bakers’ and snack producers’ need for an ingredient to help them reduce the sodium levels in their products, Micron Saltalso addresses the snack food industry’s concern about cost and product labeling. “Ingredients used to replace salt can be very costly and may be of concern for labeling purposes,” Bishop explains. “By introducing an ingredient that is labeled as salt, there is no label change.”

Minneapolis-based Cargill Inc., meanwhile, took a “flaky” approach when developing its FlakeSelect portfolio, which comprises FlakeSelect KCl (potassium chloride), FlakeSelect KCl/Salt, FlakeSelect KCl/Sea Salt and FlakeSelect Sea Salt. “It really takes advantage of Cargill’s compacted flake technology,” says marketing manager John Franklin. “We’ve been manufacturing flaked salt for several years and are looking at new ways of leveraging this expertise by using potassium chloride in a couple of the formulations.”

The patent-pending technology combines salt and other ingredients by applying pressure to the ingredients to create a clustered, thin flake with uniform consistency, low bulk density, high solubility and a large surface area. “The theory—and what food manufacturers have found—is that when you have something that has a bigger surface area, you get more of a burst of flavor on your tongue,” Franklin says.

Available in four cut sizes, FlakeSelectvarieties are being targeted to reduce sodium in snacks, baked goods and processed foods.

A matter of taste

Because many consumers perceive low-sodium foods to be less flavorful than their salty counterparts, some bakers and snack producers rely on flavor enhancers to boost their products’ flavor without increasing their sodium levels.

Introduced in May 2011, by Kikkoman Sales U.S.A. Inc., San Francisco, Kikkoman Natural Flavor Enhancer NFE-PY is a powdered version of a naturally-fermented soy sauce with a unique flavor profile. “There is little soy sauce flavor evident,” says Joe Leslie, national industrial sales manager at Kikkoman Sales U.S.A. “What NFE-PY does provide is a huge umami boost, much like monosodium glutamate (MSG), while maintaining a clean and natural ingredient label.”

Until now, Kikkoman products have been used primarily in flavor systems for snack foods and bakery items. “Sodium reduction has been an exciting new direction for us,” says Leslie. “So far, we have seen NFE-PY used in such products as bagels, pizza crusts, low-sodium breads, tortilla shells and snack chips.” He adds that the flavor enhancer also can be used with potassium chloride products because it masks off flavors.

“We’ve done independent testing on several food products and have seen a 33- to 50% sodium reduction without any loss of flavor pleasantness, flavor intensity or salty taste,” Leslie says. “The best news is that our NFE-PY is all-natural, made in the U.S.A., are kosher and are very low in cost.”

Tokyo-based Ogawa & Co. Ltd., meanwhile, recently introduced a Salt Enhancer for manufacturers that don’t want to use potassium chloride in their reduced-salt dough and snack products. The natural flavor is purified to remove unnecessary flavors that could affect the original flavor profiles of the products to which it’s added, making it suitable for use in a wide variety of consumables, including baked goods and snacks.

Available in powder and liquid formulations, Ogawa’s Salt Enhancer also allows bakers to reduce the amount of sodium in bread by as much as 50%, without changing its overall profile. However, according to the company’s Marketing and Sensory group, a 25% reduction results in products with flavor profiles extremely close to the original offerings.

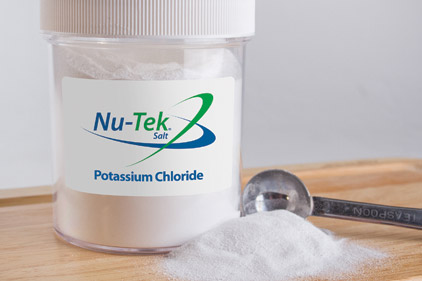

Launched in 2011, Nu-Tek Salt’s MPC 14510 modified potassium chloride offers food manufacturers a cost-effective salt substitute without the bitter taste often associated with potassium chloride. “This product offers sodium reduction by up to 50%, a number that was previously thought impossible without changing functionality or taste,” says Don Mower, president and COO of the Omaha, Neb.-based company.

MPC 14510 contains less than 0.1 % sodium and can be blended with sodium chloride, making the patented product “a healthy solution for reduced-sodium initiatives, including processed meats, dairy and bakery, where a majority of consumer sodium intake comes from,” says Mower.

For many consumers, the solution to creating low-sodium versions of their favorite baked goods and snacks likely comes down to manufacturers just reducing the amount of salt in their products’ recipes. Bakers and snack makers know, however, that creating flavorful, reduced-salt products is a much more complicated process.

“Salt plays a very functional role in a number of foods—bakery and snacks foods, first among them,” says Cargill’s Franklin. “You can’t say, ‘we’ll pull most of it out of there, but we’ll leave a little bit, so it tastes right.’ Salt impacts proofing time, gluten development and everything about the yeast fermentation, as well as the flavor. It’s really a balance.”

Fortunately, today’s low-sodium ingredients are helping food manufacturers find their balance.