The six-day fair in Munich showcased a wide product spectrum for the baking and confectionery sector, with more than 1,100 exhibitors that transformed the Messe München exhibit hall into ‘the world’s largest bakery.’

Held every three years, iba, the international tradefair for baking, Sept. 16-21 in Munich, again set new standards and offered exciting insight into baking’s future trends. A platform for innovations from all areas of the industry, iba 2012 delivered what show organizer Zentralverband des Deutschen Bäckerhandwerks (German Bakers’ Confederation) says is an overview of all new products on the market.

International in scope, iba 2012 captured the essence of the global baking market, as 59% of the 1,171 exhibitors were based outside Germany. In fact, more than 680 companies from outside Germany flew their countries’ flags in Munich. Companies from 55 different countries and from all five continents attended. Technical expertise was neatly packaged into six country pavilions that represented small- and medium-sized businesses.

The range of solutions, products, brands and technologies was abundant from the exhibitors within a massive area totaling 132,000 sq. m. Approximately 80,000 bakers and confectioners attended the tradefair during its six-day run.

Besides Germany, the top eight nations participating were Italy, the Netherlands, France, the U.S., Austria, Turkey, Great Britain and China. Each exhibitor had access to a multitude of strong export markets, which is critical in light of the unstable situation for some markets. As many companies are increasingly reliant on exports, iba 2012 was a good place to find advances in new technology and equipment that can help save energy, optimize processes, manufacture high-quality products and boost turnover.

There was also a full range of ingredients, including flavors, baking agents and creams, as more than 200 manufacturers presented the latest ingredients for the baking and confectionary industries. Millers and manufacturers of baking agents and ingredients on hand at the World Market for Baking showed off their various product lines. The list included Backaldrin, Jung Zeelandia, Ireks, Keesko, Martin Braun, Lesaffre, Uniferm, Unifine and Werhahn Mühlen. Visitors also found assorted yeast, filling, glazing, ice cream and flour products.

“Raw ingredient suppliers are traditionally very well represented at the iba, as the event provides an insight into the changing requirements of consumers,” explains Peter Becker, president of the Zentralverband des Deutschen Bäckerhandwerks. “For instance, increasing importance is being attached to the raw ingredients and materials required to make baked goods for allergy sufferers, as well as products that can meet the needs of current diet trends, such as the demand for low-carb foods. Likewise, this year’s iba showcased the industry’s response to the growing demand for original grain types that has emerged among bakers.”

In total, ingredient specialists filled an area of around 17,000 sq. m. across the 12 halls of the tradefair. All areas of the baking and confectionery industry were covered by the companies in attendance at this year’s iba.

Pavilions aplenty

Several country pavilions featuring international guests included participants from Brazil, China, Great Britain and the U.S. A new feature this year was a joint booth from Croatia and the Czech Republic. The 135-sq.-m. Croatian stand, supported by the Chamber of Commerce and the Ministry for Agriculture, was manned by six companies that specialize in raw materials and technology. The Czech Republic’s stand will featured five companies and was funded by the national Ministry for Industry.

In addition, the iba summit held on Sept. 15 featured John Dalli, European Union (EU); Commissioner for Health and Consumer Protection, as one of the speakers. Dalli discussed the impact of the agricultural commodity market on the consumer.

Our publisher, Jeff Heath, walked some 50 miles through the enormous show and gathered a wealth of information on new developments.

The following is just a brief selection of the many offerings he found, as space limits us from showcasing everything. For more information about the program, visit to www.iba.de/iba-summit. For other iba show details, visit the iba website at www.iba.de.

Product Roundup

Mixers and more

The heavy-duty Topos 300 KG Double Spiral mixer, a removable-bowl, double-spiral dough mixer (RBDSM) from Topos Mondial Corp. (www.toposmondial.com) is built for demanding production needs. Reinforced, double-spiral mixing agitators with dual stripper bars offer faster and more thorough dough mixing in less time. The agitators are driven via a heavy-duty, high-efficiency, two-speed drive motor connected to Kevlar reinforced timing belts and oversized bearing support assemblies. The double-spiral agitator design handles both soft and firm dough mixing tasks.

The heavy-duty Topos 300 KG Double Spiral mixer, a removable-bowl, double-spiral dough mixer (RBDSM) from Topos Mondial Corp. (www.toposmondial.com) is built for demanding production needs. Reinforced, double-spiral mixing agitators with dual stripper bars offer faster and more thorough dough mixing in less time. The agitators are driven via a heavy-duty, high-efficiency, two-speed drive motor connected to Kevlar reinforced timing belts and oversized bearing support assemblies. The double-spiral agitator design handles both soft and firm dough mixing tasks.

The unit’s entire dough-mixing zone is constructed from heavy-duty stainless steel. The mixer bowl bonnet can be connected to both dry and liquid bulk ingredient feeders.

The mixer is also said to be easy to clean and access and has six leveling legs that enable users to clean the floor beneath it.

Reading Bakery Systems (www.readingbakery.com) featured two of its core capabilities at iba 2012: Flexible extruded-snack; and exact continuous mixing systems.

Reading Bakery Systems (www.readingbakery.com) featured two of its core capabilities at iba 2012: Flexible extruded-snack; and exact continuous mixing systems.

The flexible extruded-snack system is completely automated and allows snack manufacturers to produce pretzel shapes, sticks and other extruded bread snacks on the same production line. The system affords production volumes up to 1,000 kg.

per hour.

RBS says its exact continuous mixing systems significantly improve the quality and consistency of dough, producing a better finished product. Systems are available for the baked snack, cracker, sweet goods, pizza, tortilla, bread and buns industries.

The Fritsch IMPRESSA bread system from Fritsch GmbH (www.fritsch.info) handles all types and batch sizes of soft dough. The system’s SoftProcessing technology treats soft dough gently from the beginning to the end of the process. The Fritsch Satellite Head, the “heart and soul” of Fritsch SoftProcessing, creates dough sheets quickly and with “the right” thickness, while dough transfer tools move dough without pulling and pushing it. A synchronized guillotine also avoids unnecessary stretching or jamming of the dough. Other features include specially-formed and coated belts, scrapers and brushes that help keep the system clean and flour dusters that deliver a precise, uniform flour curtain. IMPRESSA bread system’s modular components enable bakers to configure the bread line that best suits their needs.

Originally intended to produce liquid sponge, Rapidojet from Bakery Concepts International, LLC (www.bakeryconcepts.net) has evolved into a system that produces complete dough and much more. The continuous mixing technology offers bakers numerous benefits, including increased worker and product safety, increased product quality and output versatility, reduced ingredient and labor costs, reduced power consumption, rapid changeover and easy disassembly and cleaning. The unit has a solid 12-gauge 302 stainless-steel frame; lockable doors; heavy-duty, mainframe support tubing; heavy-duty, washdown wheels; high-torque, energy-efficient motors; a large, vertical dry-ingredient hopper; and more.

Originally intended to produce liquid sponge, Rapidojet from Bakery Concepts International, LLC (www.bakeryconcepts.net) has evolved into a system that produces complete dough and much more. The continuous mixing technology offers bakers numerous benefits, including increased worker and product safety, increased product quality and output versatility, reduced ingredient and labor costs, reduced power consumption, rapid changeover and easy disassembly and cleaning. The unit has a solid 12-gauge 302 stainless-steel frame; lockable doors; heavy-duty, mainframe support tubing; heavy-duty, washdown wheels; high-torque, energy-efficient motors; a large, vertical dry-ingredient hopper; and more.

Dividers and molders

WP Kemper (www.wp-kemper.de), a WP BakeryGroup company, showcased the CleanTec (CT) version of its Soft Star dough-dividing and molding machine. Designed according to the company’s philosophy that dirt should not occur but, if it can’t be avoided, it must be easy to recognize and remove, the Soft Star CT offers easy accessibility to the machine’s various components without the use of tools; parts that are easy to remove, clean and reinstall; and separate drive and product areas. Other features include a movable, stainless-steel-and-plastic chamber; a plastic measuring drum; a modular, intermediate belt; a central flour-feeding system; and an increased clearance height of 220 mm.

WP Kemper (www.wp-kemper.de), a WP BakeryGroup company, showcased the CleanTec (CT) version of its Soft Star dough-dividing and molding machine. Designed according to the company’s philosophy that dirt should not occur but, if it can’t be avoided, it must be easy to recognize and remove, the Soft Star CT offers easy accessibility to the machine’s various components without the use of tools; parts that are easy to remove, clean and reinstall; and separate drive and product areas. Other features include a movable, stainless-steel-and-plastic chamber; a plastic measuring drum; a modular, intermediate belt; a central flour-feeding system; and an increased clearance height of 220 mm.

The Soft Star CT is built for a weight range of 12-180 g. and is able to process 36,000 pieces per hour at 60 cycles per minute.

The Vemag single-outlet dough divider (VDD) with Servo Cutter 807 from Reiser (www.reiser.com) adds versatility and portioning accuracy to dough production lines. The VDD 807 handles all types of sandwich breads, buns and rolls. It can be easily adjusted to produce a range of exact-weight portions and crumb structures. The Vemag also handles absorption rates from 45-95%. The Servo Cutter 807 ensures clean cuts, accurate portions and high production rates.

Ovens and other equipment

The MIWE ideal M multiple-deck baking oven is completely flexible, supports a large variety of products and can be expanded as needed in the future, according to MIWE Michael Wenz GmbH (www.miwe.com). Every oven in the MIWE ideal M can be controlled separately. The individual modules work autonomously, as each has its own burner and circulator, giving the entire system high operational reliability. As a result, the concept enables users to conserve staff by streamlining work; time due to rapid, highly-coordinated process workflows; and products due to reliable, high quality output.

The MIWE ideal M multiple-deck baking oven is completely flexible, supports a large variety of products and can be expanded as needed in the future, according to MIWE Michael Wenz GmbH (www.miwe.com). Every oven in the MIWE ideal M can be controlled separately. The individual modules work autonomously, as each has its own burner and circulator, giving the entire system high operational reliability. As a result, the concept enables users to conserve staff by streamlining work; time due to rapid, highly-coordinated process workflows; and products due to reliable, high quality output.

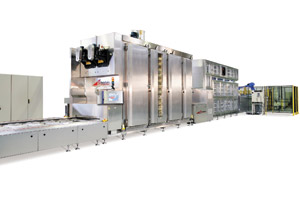

Dunbar Systems Inc. (www.dunbarsystems.com), which designs, sells, installs and supports custom-automated, cost-effective systems for commercial bakeries, brought more than 30 years of experience and knowledge of 1,400 successful production bakery installations to attendees at iba 2012. Dunbar Systems built its reputation by working with a variety of equipment manufacturers to source the best available equipment for each job. Among its equipment offerings are Auto-Bake Serpentine ovens and systems, mixers, depositors, dough handling systems and proofers.

Dunbar Systems Inc. (www.dunbarsystems.com), which designs, sells, installs and supports custom-automated, cost-effective systems for commercial bakeries, brought more than 30 years of experience and knowledge of 1,400 successful production bakery installations to attendees at iba 2012. Dunbar Systems built its reputation by working with a variety of equipment manufacturers to source the best available equipment for each job. Among its equipment offerings are Auto-Bake Serpentine ovens and systems, mixers, depositors, dough handling systems and proofers.

Laminators and processing equipment

The high-volume Koenig Menes 600 laminating line from Koenig Bakery Systems (www.koenig-rex.com) gently shapes 85% hydration dough with two hours of fermentation into fluffy ciabatta. The system features twin satellite head (TwinSat) technology and stress-free operation with results that can be seen in the bubbly dough. The same versatile line produces beautiful baguettes and round sweet rolls.

The high-volume Koenig Menes 600 laminating line from Koenig Bakery Systems (www.koenig-rex.com) gently shapes 85% hydration dough with two hours of fermentation into fluffy ciabatta. The system features twin satellite head (TwinSat) technology and stress-free operation with results that can be seen in the bubbly dough. The same versatile line produces beautiful baguettes and round sweet rolls.

Rademaker BV (www.rademaker.com) introduced its latest offering in high-speed croissant processing equipment: The Rademaker croissant machine. The machine molds straight croissants at 150 rows per minute and at capacities of more than 100,000 pieces per hour. The new design is fully washable for easy sanitation and features fewer and easier-to-use changeparts for reduced changeover times. Bakers can complete their Rademaker croissant lines by adding croissant-filling equipment, as well as automation for bending, pinching and panning. All Rademaker equipment is supported in North America by Rademaker USA, Hudson, Ohio.

Rademaker BV (www.rademaker.com) introduced its latest offering in high-speed croissant processing equipment: The Rademaker croissant machine. The machine molds straight croissants at 150 rows per minute and at capacities of more than 100,000 pieces per hour. The new design is fully washable for easy sanitation and features fewer and easier-to-use changeparts for reduced changeover times. Bakers can complete their Rademaker croissant lines by adding croissant-filling equipment, as well as automation for bending, pinching and panning. All Rademaker equipment is supported in North America by Rademaker USA, Hudson, Ohio.

The Twist & Place machine from Rondo Burgdorf AG (www.rondo-online.com) produces a variety of tight and loosely-twisted pastries, from traditional savory products and sweet goods to filled products. Once twisted, the dough strings are automatically panned onto tray and cut to length on a separate cutting module. Biscuit and snack manufacturers, in particular, will appreciate the machines wide product variety, high level of automation and easy operation.

The Twist & Place machine from Rondo Burgdorf AG (www.rondo-online.com) produces a variety of tight and loosely-twisted pastries, from traditional savory products and sweet goods to filled products. Once twisted, the dough strings are automatically panned onto tray and cut to length on a separate cutting module. Biscuit and snack manufacturers, in particular, will appreciate the machines wide product variety, high level of automation and easy operation.

Miscellaneous sightings

Shaffer mixers from Shaffer (www.shaffermixers.com), a Bundy Baking Solutions company, come standard with positive-pressure side seals. The seals are made from a proprietary, flexible, food-grade material that conforms to the radius of the mixers’ canopy. The front and rear seals are made of an ultra-high molecular weight (UHMW) material that also conforms to the canopy’s shape. These components, along with the special filler used in the corners where the bowl side and front seals meet, create a system that virtually eliminates flour leakage from the mixing bowl during the mix cycle. As pressure builds during the mixing cycle, the seals push tighter against the canopy. The seals’ design also eliminates crevices and ledges found with other seal designs.

Shaffer mixers from Shaffer (www.shaffermixers.com), a Bundy Baking Solutions company, come standard with positive-pressure side seals. The seals are made from a proprietary, flexible, food-grade material that conforms to the radius of the mixers’ canopy. The front and rear seals are made of an ultra-high molecular weight (UHMW) material that also conforms to the canopy’s shape. These components, along with the special filler used in the corners where the bowl side and front seals meet, create a system that virtually eliminates flour leakage from the mixing bowl during the mix cycle. As pressure builds during the mixing cycle, the seals push tighter against the canopy. The seals’ design also eliminates crevices and ledges found with other seal designs.

American Pan (www.americanpan.com), a Bundy Baking Solutions company, offers a series of pan options to address the growing sustainable technology trend—the ePAN, introduced in 2007 and the e2PAN, introduced in 2010. The company is currently working on a new pan that it says is up to 50% lighter than traditional pans and cools 17-25 % faster. Bakers will appreciate the energy savings and other benefits the design can bring to their operation.

American Pan (www.americanpan.com), a Bundy Baking Solutions company, offers a series of pan options to address the growing sustainable technology trend—the ePAN, introduced in 2007 and the e2PAN, introduced in 2010. The company is currently working on a new pan that it says is up to 50% lighter than traditional pans and cools 17-25 % faster. Bakers will appreciate the energy savings and other benefits the design can bring to their operation.

Shick USA’s (www.shickusa.com) AIM batch-management software solution is designed to integrate with new and existing automated ingredient-handling systems. AIM supports a number of different database platforms, is a client/server software product, was built around the Microsoft .Net framework and can be accessed from any PC on the local network. It offers ingredient and formula management, production scheduling, data collection, lot tracking, reporting and user security.

Shick USA’s (www.shickusa.com) AIM batch-management software solution is designed to integrate with new and existing automated ingredient-handling systems. AIM supports a number of different database platforms, is a client/server software product, was built around the Microsoft .Net framework and can be accessed from any PC on the local network. It offers ingredient and formula management, production scheduling, data collection, lot tracking, reporting and user security.