Silicone seals

Packaging liners

888-379-9695 • www.thermopod.net

Food texture analyzer

703-444-1870 • www.foodtechcorp.com

Laser sorter

Equipped with an Enygma sort engine, a re-engineered and patented Chycane infeed chute, a new ejection manifold and effective, reliable lasers, the Taurys digital laser sorter handles higher incoming defect loads, increases detection resolution and improves the accuracy of defect and foreign material (FM) removal, says Key Technology. The Taurys is a 100%-digital laser sorter that eliminates the transmission of analog laser signals and is unaffected by noise or interference. Its laser scanner, which typically operates at 12,000 revolutions per minute (rpm), now can operate at up to 24,000 rpm to increase inspection resolution and identify even smaller defects and FM. A 47-in.-wide inspection zone enables the Taurys to sort a maximum capacity of 3 to 15 metric tons (3.3 to 16.5 short tons), depending on the product.

509-529-2161 • www.key.net/products/taurys

Wrapper

The 3M-Matic wrapper FL360 from 3M applies tape to cases that are typically banded. The tape machine provides a uniform application of Scotch box sealing tape or Scotch filament tape simultaneously around corrugated cases, closing up to nine per minute. The tape is applied 360 deg. around the case, similar to metal strapping. The tape improves packaging throughput and box security, according to the company, which makes the case more secure and easier to handle. The FL360 can be used for food-processing applications where straps could slide off and result in an unsecure case, among others.

888-364-3577 • www.3m.com/packaging

Holiday bakeware

Welcome Home Brands’ new self-standing, oven/freezer-safe Holiday Paper Bakeware Collection offers a variety of convenient, time-saving baking and serving options. In addition to making it easy for commercial bakers, restaurants, hotels and others to bake, serve, store and sell baked goods in one form, the bakeware doesn’t require pre-greasing or cleanup, can be placed directly in the oven, is oven-safe up to 400 deg. F. and is freezer-safe. Available in classic holiday colors (red, green and white) with diagonal stripes, polka dots, wrapped holiday gifts and snowflakes, the collection features three loaf pan sizes, fluted baking cups and a cube baking cup that is smaller than a traditional cupcake mold.

914-696-0010 • www.welcomehomebrands.com

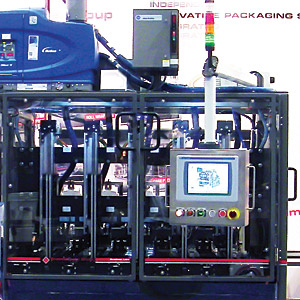

Case former

Bradman Lake’s new case-forming machine, the HSS300 all-servo glue case former, reaches speeds up to 300 cases or trays per minute and can erect cartons and trays using hot-melt glue or a four-corner lock. It uses a servo-powered, reciprocating “shuttle” method of feeding case blanks into a forming tool, guaranteeing quick and easy setup using factory-set tooling. The machine can erect various board types, including chipboard and corrugated. Case types include three-flap closure, single-flap closure with dust flaps, hooded lid closure, turnover end-style and turnover end-style with frame view. The HSS300 is available as an individual unit or as part of an integrated system with Bradman Lake’s wrapping, product-loading and case-packing equipment.

704-588-3301 • www.bradmanlake.com

Loading system

Kliklok-Woodman’s CLS120 Cascade Loading System is an independent product-handling unit featuring fully adjustable, three-stage, vertical rotor vanes that collate, stack and transfer bags, sachets, ready meals and pizzas. The product timing system consists of three stage rotary drop stations, which align the incoming product timing to the position of the output device, most commonly a moving cartoner PIC pocket. Multiple units can be integrated to meet high-speed line requirements.

770-981-5200 • www.kliklokwoodman.com

Distribution system

Bosch Packaging Technology and its partner Rotzinger AG recently introduced the Transver SDP product distribution system. The system features a modular depositing pullnose station designed for fully automated format changeovers and simple adjustment to product-specific characteristics. The station’s modular, stainless-steel frame withstands cleaning solvents and processes, while its double wing doors allow full access. A noncontact belt system operates without side guides, ensuring high product quality, even for sticky and fragile food products such as cereal bars, muffins, soft biscuits, cupcakes, chocolates and irregularly-shaped baked goods. The Transver SDP can be integrated upstream into existing packaging lines, giving manufacturers the benefit of a single-source solution supplier.

715-246-6511 • www.boschpackaging.com

Dough moulder

616-784-3111 • www.bakerperkinsgroup.com

Food-safe lubricant

Klüberfood NH1 CH 2-220 oil from Klüber Lubrication North America L.P. is designed for lubricating high-temperature chains in baking applications. The fully synthetic, ester-based lubricant can operate at extreme temperatures for longer periods and without residue buildup while protecting chain components from increased wear. According to the company, users benefit from reduced consumption, cleaner operations, reduced noise and no smoking. The NSF H1-registered lubricant also keeps food safe from incidental contact.

800-447-2238 • www.klubersolutions.com

Post-frying dryers

Macrowave Post-Frying Dryers from Radio Frequency Co. Inc. help producers of fried snack foods and toppings that are conveyed through continuous fryers meet the challenge of obtaining the appropriate color and moisture content. The dryers use radio frequency (RF) energy, which preferentially heats and dries the moist portions of loads being conveyed through a system, providing the means to dry product bed depths of up to 4 in., thus reducing the length of the dryer, while maintaining moisture uniformity.

508-376-9555 • www.radiofrequency.com