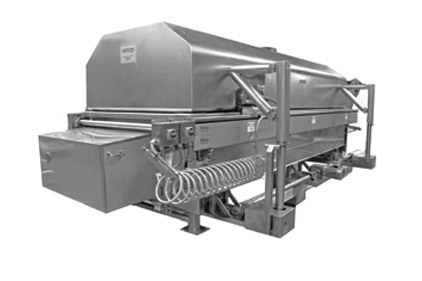

Chip cookers

The Batch-Pro series kettle-style cookers for potato and vegetable chips offer proven capacities of 650-700 lb. per hour, according to FOODesign Machinery & Systems Inc. In addition, the systems—available for use with natural gas, propane and propane/butane—are built to exceed thermal efficiency of up to 84%. The company says the engineered thermal-heating systems incorporate flow-control systems with tube configurations that ensure even heating throughout the cooker and continuous operation without tube degradation. Batch-Pro cookers come in a wide range of configurations. Systems are available with automated stirring, continuous fines removal, continuous filtering, integrated hood and lift, demisters and programmable logic controllers.

503-685-5030 • www.foodesign.com

Aerators

Unifiller Systems now offers the Shufflemixer series, a line of aerators from Shuffle-Mix, that aerate and deposit cream, bavarois, mousse and meringue. Designed for pie and cake decorating, the Shufflemixer increases product volume up to three times more than a traditional batch mixer, says Unifiller. This results in a more stable product that holds its shape and form longer. Available in four sizes, the Shufflemixer offers fast startup and switchover, with minimal product loss. The system has a programmable logic controller and is equipped with a frequency-controlled product pump and an automatically controlled airflow meter. It can be operated through a color touchscreen and is equipped with up to 40-recipe storage.

888-733-8444 • www.unifiller.com

Spraying solution

Tna’s intelli-spin 700 series spinning disc technology is designed to fit on production lines running snacks, nuts, confectionery and other products requiring an even coating on the top and/or bottom as they travel along a conveyor. The unit uses overlapping spinning disc spray patterns to control the spray application. The spinning disc handles up to 2.5 liters of oil per minute per disc, of which 20% is accurately sprayed onto the product. The remainder of the liquid is captured, channeled back into tanks, filtered and reused to reduce waste and raw material costs. The tna intelli-spin 700 is available in modular units, with easily replaceable spray heads in five widths (800, 1000, 1,200, 1,500 and 2,000 mm).

972-462-6500 • www.tnasolutions.com

Temperature probe

ECD BakeWATCH received a U.S. patent in October for its latest innovation, the Breadometer. The food probe is designed to help baking professionals ensure product consistency, optimize taste and texture and enable high yields. The device finds the coldest area of a baked good with a single probe insertion, and locates five thermocouples into the dough. A sixth channel remains outside to measure oven-zone temperature performance along the conveyor or shelf. The end of the stainless-steel shaft cleaves into the dough for a clean insertion, while a stop disk on top sets a repeatable depth. MAP software extracts the data channel at the depth that took the longest to reach the required temperature and uses it to automatically calculate and report S-curve data.

800-323-4548 • www.bakewatch.com

Food-safety tests

3M Food Safety’s new 3M Petrifilm Rapid Yeast and Mold Count Plate has received certification from the AOAC Research Institute’s Performance Tested Methods (PTM) Program. Introduced in September 2013, the test enables food manufacturers to detect yeasts and molds in as little as 48 hours. The AOAC-PTM certification validates 3M’s test as equivalent to or better than standard reference methods of enumerating yeast and mold within food products, including frozen bread dough and ready-made pie.

888-364-3577 • www.3M.com/foodsafety/RYMAOACPTM

Vacuum cups

FIPA Inc.’s new Bernoulli vacuum cups offer bakers and snack producers a solution for handling delicate products. The vacuum cups’ design is based on the Bernoulli Principle: Compressed air flows through a very fine nozzle on the underside of the vacuum cup and is accelerated. The rapid airflow produces underpressure and acts like an air cushion on which products float, almost without contact. The vacuum cups are made from FDA-compliant polyetheretherketone (PEEK) and have a hygienic design and resistance to chemicals. In addition, they’re up to 75% lighter and offer two times more suction power than conventional Bernoulli cups made from aluminum.

919-651-9888 • www.fipa.com