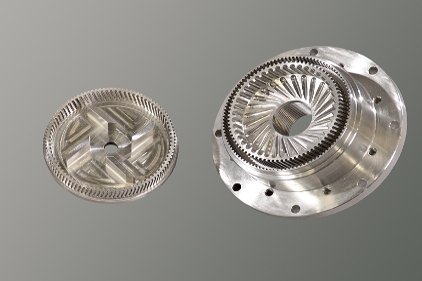

Hauppauge, NY, January 13, 2014 – The Ross MegaShear Ultra-High Shear Mixer is designed for homogenizing dispersions and disintegrating large solid particles or droplets suspended in liquid. A unique inline rotor/stator design, the MegaShear’s mixing head (US Patent No. 6,241,472) turns at tip speeds well over 11,000 ft/min and generates extremely complex flow patterns without sacrificing throughput. This subjects the product to intense mechanical and hydraulic shear, rapidly resulting in a very fine particle size distribution.

In a typical process set-up, raw materials are combined in an agitated vessel and the resulting slurry, paste or emulsion is introduced to the MegaShear which behaves like a centrifugal pumping device. Materials are fed by gravity or pumped to the mixer. When an auxiliary pump is used, the MegaShear can handle viscosities up to around 200,000 cP or higher.

For many applications, the MegaShear offers a viable alternative to expensive high pressure homogenizers. These include submicron emulsions and dispersions, as well as formulations that degrade upon exposure to excessive shear. Advantages include lower equipment cost, significantly shorter cycle time, no clogging, faster changeover and easier maintenance.

For more information on Ross Ultra-High Shear Mixers or to speak with a mixing specialist about your application, call 1-800-243-ROSS(7677). Ask about our no-charge mixer testing services and trial/rental program.

Contact Info:

Chris Ross, Vice President, Sales

Charles Ross & Son Company

710 Old Willets Path

Hauppauge, NY

P: 1-800-243-ROSS