Company: Lock n’ Pop, Douglasville, GA

Website: www.locknpop.com

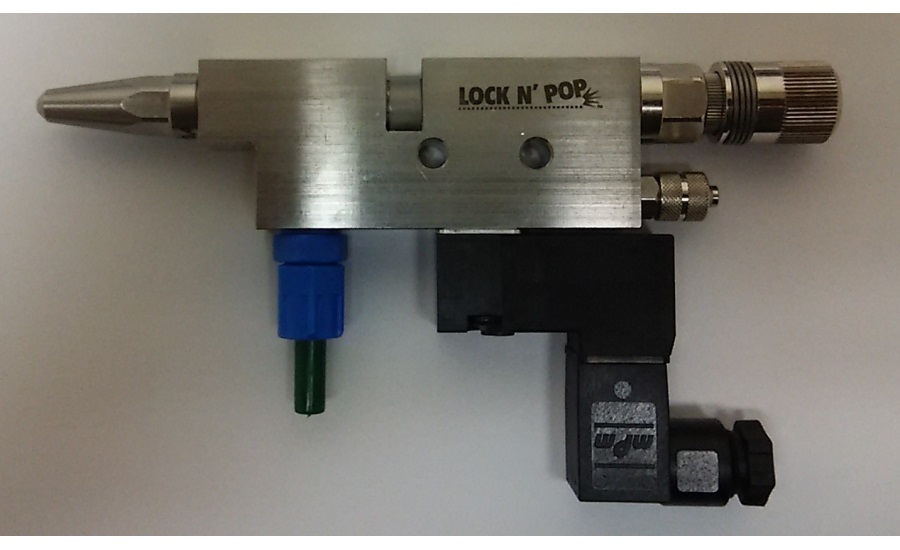

Equipment Snapshot: Lock n’ Pop, a load containment solution provider from Muller LCS, has introduced a MMDV extrusion valve for its water-based cohesive that forms a chemical bond with package surfaces and holds firm until it’s time to unstack pallets. The valve also allows Lock N’ Pop’s cohesive to be applied quickly with exact intermission cycles and can be used with low pressures, accommodating most plant air capabilities. Lock n’ Pop says its water-based cohesive is stronger than stretch wrap alone, is cold applied and doesn’t leave a sticky residue or harm packaging surfaces when products are unstacked or separated. In addition, it reduces the need for traditional packaging—stretch film, slip sheets, dunnage bags, corner boards and more—while maintaining proper load security. Formulated with FDA-approved ingredients, the cohesive can be applied to refrigerated or frozen goods.