Sustainability continues to be a priority for bakers and snack manufacturers for a variety of issues: Federal and state regulations are requiring manufacturers to be more energy efficient and reduce waste. Consumers continue to scrutinize the ingredients in their foods and question aspects like how “processed” they are. Rising energy and supply prices are prompting companies to look for new ways cut costs.

The key to addressing many of these sustainability issues, more bakers and snack producers are discovering, is investing in equipment—including in conveyors and belts—designed with efficiency in mind.

Sustainably sanitary

Pneumatic conveying systems, for instance, are commonly used to recycle excess toppings—sugar, salt, sesame seeds, cornmeal, chopped nuts and more—from conveyor belts for refilling topping spreaders with “excellent economic return and reduced waste product,” says David Kennedy, business development manager, Vac-U-Max, Belleville, NJ. The conveying systems also can be used to transport individually wrapped products to bagging or carton-filling machines.

Vac-U-Max’s pneumatic batch-weighing hopper feed systems convey major, minor or micro ingredients, such as powders, granular food ingredients, nuts, and other bulk ingredients, that allow minimal product degradation when pneumatically conveyed. The systems can convey ingredients from drums, bags, bulk bags, intermediate bulk and flexible intermediate bulk containers, or super sacks, as well as discharge ingredients to packaging lines or other destinations.

The systems offer dust-free operation, allowing for safer and cleaner plant environments. Controls let operators select batching times or desired destinations, while a tool-free design facilitates maintenance and easy batch changeover.

“The ability to create recipes based on preprogrammed formulations allows processors to save on food ingredient costs over time, allowing for greater inventory control and overall end-product cost savings,” says Kennedy. “In some instances, expensive ingredients can be tweaked as a result of increased accuracy of food ingredients going into the process, ultimately saving time and money on ingredient costs.”

Heat and Control Inc., Hayward, CA, recently added two FastBack conveyors designed for productivity, sanitation and ease of use to its line of FastBack horizontal motion conveyors.

Based on the FastBack E-drive—which can be reused with different pans when equipment layouts change—the FastBack 300E conveyor is more robust and easier to maintain than the FastBack 260E, says Blake Svejkovsky, manager of product handling systems, Heat and Control. It also offers the company’s highest level of safety and hygienic operation and comes with a choice of standard or stainless steel motors. Other design features include easy access to electronic components; sloped, self-draining stainless steel covers with flush doors and smooth sides; gentle motion; and quiet operation. The model handles snacks, baked products, premixed blends and more.

Designed for whole potatoes and other product laning applications, Heat and Control’s new FastBack potato laning conveyor gently meters a consistent flow of potatoes to slicers, as well as improves productivity in other product laning applications, says Svejkovsky. Its simple design eliminates overhead support structures and mechanical components over food contact areas, and offers more-open access for cleaning.

Energy savings is also top-of-mind for equipment manufacturers today. “Intelligrated motorized roller conveyors operate in short zones and run on demand,” says Tim Kraus, manager, product management, Intelligrated, Mason, OH. “This translates to significant energy reduction compared to traditional conveyor technologies.”

Intelligrated’s ZoneFlex Advanced zone control maximizes carton control and increases throughput for zero-pressure accumulation conveyor applications. Its patented “neighborhood mode” feature provides unprecedented carton control, according to Kraus, slowing down product before accumulation to minimize damage, carton rotation and side-by-sides. This allows the conveyor to run at faster-than-typical speeds, increasing throughput by as much as 45 percent.

Kraus adds that the system offers all the benefits of Intelligrated’s original ZoneFlex zero-pressure zone control solution for Accuglide and IntelliQ accumulation conveyors.

Kofab’s Eleveyor, Curveyor, Doughveyor and the Troughveyor—all part of the Signature Design conveyor series—are designed to use any of the manufacturer’s positive drive belting, says Bill Schiltz, director of sales and marketing for the Algona, IA, company. Positive-drive belts and drive components help eliminate slippage and solve tracking issues, he adds.

In addition, Kofab designs all its conveyors without ledges that could allow product buildup, with tool-less removal of slider bed rails for clean-out-of-place (COP) cleaning and with belt lifts to facilitate cleaning of all belting surfaces. The company also recently introduced a manual quick-release take-up assembly without external threads that removes belt tension, allowing customers to clean slider bed surfaces or remove bed rails.

Kofab conveyors handle all baked goods and snacks, including bagels, bars, cookies, dough products, pastries and most any other food products. According to Schiltz, they’re often used to convey products to flow wrappers and pack-off tables for packaging.

The benefits of belts

Bakers and snack manufacturers not ready to invest a new conveying system may be able to make their existing equipment more sustainable and sanitary with new belts.

Manu Jasol, business development analyst, snack team, Intralox LLC, New Orleans, notes that the company’s belts can help customers achieve their sustainability goals in a variety of ways: by reducing water consumption through enhanced cleanability, by reducing product loss and/or improving yield, by reducing planned and unplanned maintenance, and by improving efficiency and throughput.

Intralox’s latest product for snack processors—the S900 Open Flush Grid belt in a high-heat-resistant (HHR) nylon—was developed specifically for high-temperature oven outfeed and ambient air-cooler conveyors on corn chip lines, but can also be used for other high-temperature snack applications. It’s projected to last at least three years under typical operating conditions and is designed to minimize product waste by preventing items from falling through.

“When it comes to baking, cooling, deep-freezing, steaming, drying and transporting food, steel belts are often exposed to extreme mechanical and thermal stress,” says Brian Brown, director of operations, Berndorf Belt Technology USA, Gilberts, IL, part of the Berndorf Band Group. “Berndorf Band steel belts conform to these high requirements. They even provide high quality and reliability at fluctuating operating temperatures and high load cycle, and they meet the strictest hygienic requirements.”

The steel Berndorf uses for its belts goes through a complex heat-treatment process to achieve the required tensile strength and surface for a bake oven belt, Brown says. As a result, the Berndorf CARBO13 allows baked goods to easily handle temperatures of up to 400°C. The belt’s uniformly dark, heat-absorbent surface ensures the highest product quality and energy efficiency, he adds.

Berndorf Band Engineering, also part of the Berndorf Band Group, offers the bernmatic belt-tracking roller, which provides precise belt tracking precision via adjustable rollers and has a compact design for easy installation and startup. The system monitors belt tracking continuously and reliably controls both sudden and long-term disruptions.

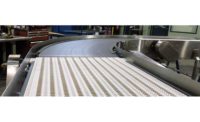

Wire Belt Company of America’s newest product for baked goods and snacks—the Compact-Grid conveyor belt—is an open-surface belt fabricated from stainless steel wire and configured with a square matrix of 10x10-millimeter openings. The open surface provides liquid flow-through, granular or powdered products, and air. “With the surface being an open matrix with 70 percent flow-through capability, the belt offers great versatility in numerous applications,” says Rick Spiak, vice president of sales and marketing, Wire Belt Company of America, Londonderry, NH. Applications include coating, dusting, powdering and enrobing.

The Compact-Grid conveyor belt also has been used in impingement and convection ovens and is simple to clean or wash down while on conveying equipment.

“Any time a baking operation can swap out a plastic modular or solid polyester and polyurethane belting for a stainless belt, they are making a change to a product that is 100 percent recyclable,” says Spiak.

At the end of the day, investments in improved reliability, more-efficient designs, better sanitary design, and increased throughput not only contribute to an improved environmental footprint, they also help improve financial sustainability.