To assure maximum food safety and high productivity, bakers and snack producers are improving their quality-control programs by investing in more-sophisticated inspection equipment that detects contaminants in a wide range of products, as well as offers lower false reject rates. Such features improve overall equipment efficiency on the line, allowing more goods to be produced in less time. The latest metal detection and X-ray equipment fulfills these needs and more at all stages of the production process.

Comprehensive measures

“Historically, many bakers and snack food processors have relied on digital sorters, metal detectors and X-ray inspection equipment at the end of production lines to check final product quality,” says John Kadinger, marketing manager, Key Technology Inc., Walla Walla, WA. “Today, we’re seeing more interest in inspecting incoming ingredients, such as nuts and dried fruit, to ensure that no quality problems are introduced along with these natural, minimally processed products.”

By removing foreign material at the beginning of the production line, food processors can reduce the risk of introducing contaminants into products at the onset. This improves production efficiency by removing foreign material before resources have been invested in processing them.

Bakers and snack manufacturers are looking for contaminants earlier in the production process when product is in bulk format, says Christy Draus, marketing manager, Eagle Product Inspection, Tampa, FL. “It is more cost-effective to remove, and easier to find, contaminants prior to processing and packaging,” she explains.

“Also, more food processors are using X-ray inspection at the packaging stage for quality-assurance checks,” says Draus. X-ray inspection has evolved to perform multiple functions besides contaminant detection, such as fill level checks, mass measurement, seal integrity and component counts, she adds. Investing in one machine that can perform all these checks not only helps bakers and snack producers better protect the quality of their products, it also saves them valuable floor space.

Rob Tiernay, director of sales, Anritsu Infivis Inc., Elk Grove Village, IL, sees growing interest in detecting smaller metal contaminants and soft contaminations—materials other than metal, such as stone, glass, ceramic and detectable plastics. “At the same time, interest has skyrocketed in X-ray inspection to achieve safety goals and protect a manufacturer’s brand,” he notes. “X-ray technology is not affected by temperature and other product characteristics that limit metal detectors’ ability to find small fragments.”

Bakers and snack producers continue to push sensitivity requirements to higher levels, adds Robert Bunting Jr., product manager for metal detection, Bunting Magnetics Co., Newton, KS. “For some products, this can be difficult, but with proper planning, and if buyers educate themselves, there are options out there,” he says. “We also see customers using networking functionality for traceability. This allows for quicker data collection and an improved data log.”

Metal detectors

Whether they choose a metal detector or X-ray inspection system, bakers and snack manufacturers have plenty of options from which to choose.

Mettler Toledo Safeline, Tampa, FL, offers the Profile Advantage metal detector, which features enhanced sensitivity. Multi-simultaneous frequency technology achieves high levels of detection sensitivities by analyzing product signal data captured across a wide spectrum of frequencies. This is processed in real time by the company’s 3S software algorithm.

In addition, product signal suppression virtually eliminates the incidence of false rejects. “Profile Advantage is a valuable inspection tool for bakery products that contain a high degree of moisture––a condition that triggers false rejects,” says Oscar Jeter, national sales manager, Mettler Toledo Safeline. “The traditional solution to this problem has been to set the sensitivity of the metal detector lower to eliminate false rejects, thereby limiting its ability to detect all contaminants. By suppressing false signals, the Profile Advantage inspects products at full sensitivity, ensuring more-effective inspection and maximizing product safety.” Fewer false rejects mean lower running costs, reduced product waste and other benefits.

ImagePhase evaluation software from Bunting Magnetics offers improved sensitivities, while decreasing false rejects. This is possible because the metal detection software “learns” the unique signal shape of the product itself, not just a linear minimum and maximum. In addition, the software can add variations such as temperature, mass and orientation, taking into account difficult manufacturing situations that may arise, according to the company.

Eagle Product Inspection offers a number of systems that are suitable for the bakery and snack industries. “The software that underpins all of our equipment, Eagle SimulTask PRO, allows us to offer contaminant detection and quality checks across a broad range of production line speeds,” says Draus. “In addition, many of our systems offer dual energy technology in the form of MDX (Material Discrimination X-ray), which can find contaminants in complex products such as cereal bars and trail mix that create busy images for X-ray technology.”

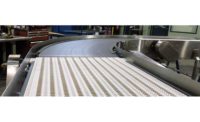

Key Technology has introduced VERYX, a line of belt- and chute-fed digital sorters that detect and remove foreign material and product defects. The technology is suitable for a variety of baked goods and snacks, including potato chips, nuts and crackers. Features include all-sided surface inspection, four-channel color cameras and self-adjusting capabilities that reportedly enable the sorter to operate at peak performance while unattended by an operator.

The latest metal detection technology makes it possible for producers to choose the most-economical detection solutions, depending on their products, according to Todd Grube, manager of inspection systems, Heat and Control Inc., Hayward, CA. “For neutral products, such as potato chips, detectors using a single high frequency provide superior, cost-effective results. However, food processors have discovered that some high-frequency detectors are more susceptible to errors caused by environmental interference. CEIA’s THS/G21 metal detectors, available from Heat and Control, negate this type of interference to reduce false rejects, while offering high sensitivity to metal contaminants.”

X-ray systems

Thermo Fisher Scientific, Minneapolis, recently added product-verification software to its NextGuard X-ray system, enabling quality inspection of product size and shape, missing pieces and counts. The software is applied to the same X-ray images used for foreign object detection, and the end result is a cost-effective way to improve overall product quality, according to Bob Ries, lead product manager, metal detection and X-ray inspection for the company. “We’ve also introduced a modular metal detection conveyor, Quickfit, which addresses the need for easy configuration, fast production and simplified maintenance and repair,” he adds.

The XR75 X-Ray inspection system from Anritsu Infivis is designed to reduce the costs associated with X-ray inspection, reportedly tripling the lifetime of the X-ray tube and detector. In addition, sanitary features include all angled surfaces, tool-less belting and curtain removal. New product setups are driven through step-by-step navigation prompts, so operators benefit from easier setup and simplified menu structures.

In addition, Anritsu Infivis has developed a proprietary process called Detection360, a four-phase program that determines the proper points of detection and inspection within each customer’s processing environment. The four phases are discovery, mapping, integration and performance.

Heat and Control offers the Ishida IX-G2 X-ray system, which employs dual-energy sensors for highly sensitive detection of low-density and thin foreign objects. By comparing images from two different X-ray energy levels, the IX-G2 analyzes the absorption of X-rays to accurately detect foreign objects by density and type of material. “This process improves detection of low-density objects, such as thin pieces of metal, glass, shell, bone and rubber in overlapping products, and those with irregular surfaces,” says Grube. “It includes functions for weight verification and the detection of missing items, incomplete filling, product defects, incorrect alignment and product trapped in package seals.”

Lightweight or unpackaged single products continue to pose a challenge for X-ray inspection due to the requirement to block radiation scatter while passing products through the system, says Ries. These types of products typically cannot be run with X-ray curtains installed. “To address this issue, Thermo Fisher Scientific has engineered customized solutions using angles, ramps, conveyors or external shields to block the radiation. When these solutions are not feasible, we recommend using large, packaged case inspection at the end of the line.”

Bakers and snack manufacturers have to deal with numerous food-safety issues, but finished products recalled due to contaminants shouldn’t be one of them.