Company: Brother Gearmotors

Website: www.brother.com

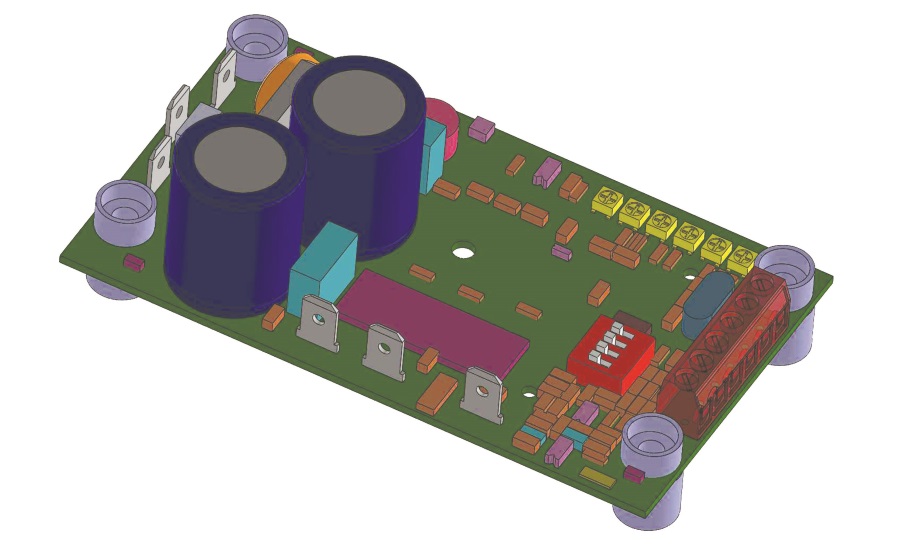

Equipment Snapshot: Brother Gearmotors, a division of Brother International Corporation that offers a wide range of ultra-reliable, sub-fractional AC gearmotors and reducers for industrial equipment manufacturers–including the food & beverage, packaging and material handling industries–has partnered with American Control Electronics (ACE) of South Beloit, IL. The agreement allows Brother Gearmotors to offer ACE’s premium selection of Variable Frequency Drives (VFDs) as a product add-on to its gearmotors portfolio.

A variable-frequency drive is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage. Providing benefits such as more precise operations control and reduced energy consumption, VFDs are particularly suitable for gearmotors included in machines typically found in a wide range of sectors including packing, materials handling, food processing and industrial applications.

A key benefit of variable frequency drives is improved speed control: VFDs allow for fine tuning the run speeds of applications that demand heightened control. VFDs allow for the use of three-phase motors in locations where only single phase power is available. This is due to the drive taking in a single phase input and outputting 3 phase power. Three-phase motors also enjoy advantages over single phase permanent split capacitor (PSC) motors, including higher starting torque and higher running efficiency.

Other benefits of the VFDs now offered through Brother Gearmotors include:

- Compact size

- Quick and easy setup; no programming

- Very competitively priced

- Same mounting envelope as DC Chassis mount drive

- Torque Limiting settings to protect mechanical components

- Torque Boost capability for hard-to-start loads

- Coast to stop or DC Injection Braking

- Increased production through tighter process control

- Extended equipment life, reduced maintenance needs