The process to improve equipment design requires interaction from many individuals and functions from both the processors and equipment suppliers. The process flow chart for design review illustrates the interaction of the processor and the equipment manufacturer to achieve the benefits of an industry model approach within the framework of the 10 Principles of Sanitary Design.

At Phase 2, the process would have the option of going to a third-party review if desired. If this option is exercised, the third-party reviewer will look at the piece of equipment in question as an additional check to verify that the equipment incorporates the desired sanitary design elements.

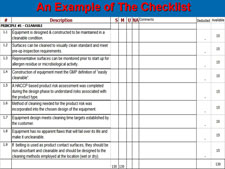

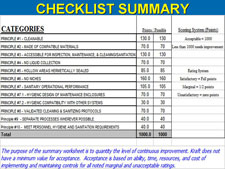

In most cases, the equipment will be acceptable if the equipment manufacturer and the processor use the checklist tool to conduct a preliminary check. Again, if at any one of these review steps the parties find the equipment unacceptable, it goes back into a redesign phase.

If the equipment is acceptable following Phases 1 and 2, the food processor purchases and installs the equipment in the plant. The significant aspect of Phase 3 (if contained in the contract) is the 90-day period for cleanability review by the processor in a real-world environment. In this way, the processor is able to actually test the sanitary design of the equipment in the individual plant environment, something that cannot be accomplished in the equipment manufacturer’s facility as discussed earlier.

During the 90-day period, the food company runs product on the new equipment and applies the appropriate cleaning and sanitizing protocols. The processor can now better determine whether the equipment is, in fact, cleanable to a GMP and HACCP level. For example, the equipment can be assessed during this time period for contamination by spoilage organisms or pathogenic organisms that may have found harborage at specific locations on the equipment. Will these organisms be easily removed by routine cleaning and sanitizing?

If, after the 90-day in-plant period, the equipment is acceptable in terms of sanitary design criteria and meets the criteria defined in the performance guarantee, the processor closes the contract. If the equipment is not acceptable, either the equipment manufacturer must redesign to address the problem or the processor must develop a sanitation control that will augment a reduction in the microbial counts for that piece of equipment. For example, the parties may determine that the types of belts used need to be reconfigured or that the finish on a piece of stainless steel allows for the creation of niches, and therefore the piece needs to undergo redesign. If the processor identifies an area that is extremely difficult to access and clean, this may indicate the need to redesign that specific area.

In conclusion, the goal with the 10 principles of equipment design for low-moisture foods is continuous improvement and enhanced robustness of our sanitation, cleaning and food safety programs. The GMA Equipment Design Working Group members and the associated processors firmly believe in working with equipment suppliers to develop equipment with the best design that will be an enabler to deliver quality and safe food products to our consumers and customers.

Editor’s Note: A food scientist by education, Joe Stout has worked for Kraft Foods for 28 years in the areas of operations, sanitation, and quality. Prior to joining Kraft Foods, he worked for Associated Coca Cola Cos. for two years. He is a registered sanitarian with the State of Pennsylvania. Stout is the facilitator of the GMA Equipment Design Group for Low-moisture Foods. In addition to having experience in equipment design in dry processes, he was also chairman of the American Meat Institute Equipment Design Task Force, and has been active with 3A and the EHEDG.

Click hereto read Part I of the “Sanitary Design as an Enabler of Food Safety” white paper.

Click hereto read Part II of the “Sanitary Design as an Enabler of Food Safety” white paper.

Click hereto read Part III of the “Sanitary Design as an Enabler of Food Safety” white paper.