When it comes to bakery customers, they all want something different. One wants healthy ingredients, while the other wants no preservatives. While that may put some bakeries into a tailspin to please them all, Masada Bakery, Norcross, Ga., keeps expanding its areas of expertise. “Our customers all have many different recipes and we have to somewhat modify things to accommodate them,” says vice president of operations Neal Ullman. “We will formulate whole product lines for certain customers. One barbecue restaurant we work with originally had five locations and now it’s all over the South, so it needs big volume.”

Serving customers within a seven-state area fresh daily, from Virginia to Key West, Fla., Masada has been in business more than 30 years. “Establishing relationships with customers has been critical,” says Ullman. “We’re very customer service-oriented.”

The producer of some 280 stock-keeping units (SKUs)—pared down from about 400—Masada bakes breads (both sliced and whole loaves) that include white and wheat, French, sourdough, ryes, pumpernickel, deli rounds, round-topped, dinner and submarine rolls, Ciabattas, hamburger and hot dog buns, bagels, pastries, croissants and muffins. With so much going on, it keeps things as flexible as it can and continues to come out with new products for retail, foodservice/institutional and private-label channels.

Growing in tough times

With a production facility/office space of 79,000 sq. ft. and a separate 29,000-sq-ft. distribution center around the corner that packs off the product trucked out each day, Masada has expanded considerably since the economy took a nosedive. Business exploded when Five Guys Burgers and Fries, Jason’s Deli and other booming restaurant chains required more and more product. “We’ve been growing in the midst of a very difficult economy,” says president Koby Stein. “The slump hasn’t affected us as much as it has other bakers. We have been growing since 2009, and keep growing. We have to be on our toes because we never know what’s coming.”

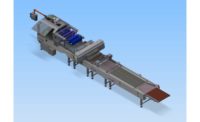

Today, the bakery’s six production lines are basically dedicated to certain types of products. To accommodate larger customers, the bakery recently added two new production lines that include 65- and 67-ft.-long tunnel ovens, computerized controls, new spiral cooling conveyors and other transport systems and additional bagging and packaging machinery.

“Anything in big volumes runs on the bread line,” Ullman adds. “We also have two bun lines—one strictly for Five Guys’ hamburger buns and other hamburger buns and another that makes Kaiser rolls and similar buns. There’s a line that runs submarine rolls and hot dog buns, and there’s a bagel line, a pastry line and a line that only runs Ciabatta bread. We also hand roll and tie knots of dough for some of the upscale restaurant clients.”

Mixing, dividing, rounding

On the day of Snack Food & Wholesale Bakery’s visit, the two new hamburger bun and Kaiser roll lines were humming along at about 35 to 40 buns/minute, accommodating some manual functions such as product transfers and tray loading. The facility runs nearly 24 hours a day, seven days a week, except for cleaning on Friday afternoons. “We start back up on Saturday at 3:30 p.m.,” Ullman says. “All of our products are produced from 5 p.m. to 4:30 a.m.”

Production starts as flour is pumped to the production lines from two indoor silos that each hold 80,000 lb. The flour is dispensed into the hopper of one of six mixers. Water, which is chilled through a set of tanks, is also pumped into the hoppers via a water jacket so that it stays cold. Everything else is scaled by hand. Yeast, dry milk and other ingredients are brought into the production area in sacks and added by hand to the mixture. “The doughs often get a few special things that give the buns more resiliency, pliability and enhanced mouthfeel,” says Ullman.

Operators bring the dough, which is made in 400-lb. batches, to the main line and feed it into the hopper of a divider and a moulder/rounder, which forms dough balls eight across. A touchscreen monitor shows operators how the line is flowing. “We only dust the dough when the customer requires it,” notes Ullman. As the dough balls progress, they drop onto large pans in counts of 24. The pans are first positioned two across beneath the main conveyor and are carried onto it as they fill with dough balls. Line operators remove the filled trays and place them onto racks that they roll to a pair of proof boxes.

Proofing, baking, cooling

One proof box holds 16 racks while the other holds 24. Depending on the product and customer requirements, the balls of dough proof from 45 minutes to 1.5 hours at temperatures of approximately 107 deg F and 87% relative humidity (RH). “Most of our bread stays in the proofer longer,” Ullman points out.

Once the buns are proofed, the racks of dough are removed from the proofer and are transported to the tunnel ovens. The pans are unloaded and placed on the oven’s long, wide infeed before the buns are baked at temperatures of or exceeding 450° F for about 12 to 14 minutes, depending on the product. Before baking, the trays of Kaiser rolls may be fed through a seed depositor. Next, the buns, which have baked to a golden brown, exit the oven onto a mesh conveyor and incline through a series of overhead conveyors up to one of two new spiral coolers that each feeds its own packaging line, and cool for about 35 minutes. A depanner removes the pans onto a lower-level conveyor while the buns are picked up using a rotating vacuum-cup system and placed onto a mesh conveyor above that leads to the spiral coolers.

Leaving the coolers, the buns convey on the main production floor to an automatic line that slices, stacks and bags them before the bags are clipped closed. “Depending on what’s running, the baggers group the buns in 4x4, 3x3 or 6x6 pack patterns, stack them and bag them according to what parameters are keyed into the computer on each line,” Ullman says.

An air blower blows open the bags just before the buns are pushed inside. The bag clips are coded by an ink-jet printer with a production date, the time and a best-use-by code. Then the bags convey through a metal detector, which is equipped on every line. If they’re rejected, the whole line shuts down and the bags start dropping into a bin. “We then check each bun or roll to find out where the contraband is and record the incident through procedures in our HACCP (Hazard Analysis Critical Control Point) program,” he notes.

The bags are then tray-packed by line operators, and the trays are stacked and brought to a set of truck bays to be transferred to the distribution center (DC) around the corner for packout and shipping.

Distribution procedures

All outbound product transferred to the DC is then case-packed and/or loaded into trucks. The DC also has room for remote storage of Masada’s dry ingredients. “We store dry ingredients here and shuttle them over to the bakery when they’re needed,” explains Marty Wahl, inventory control manager at the DC. “We bring all of the finished product over here several times a day,” he says. The tray-packed bags of buns, bread, rolls and other items are staged beneath a pick-to-light warehouse-management system (WMS), which expedites the picking and packaging processes because it uses paperless dispatching. “We’re very happy with the system—it’s all automated,” he adds. “It better manages our local routes and fresh deliveries.”

First, the trayed products are recorded in the pick-to-light WMS when they enter the warehouse. Each stack of trays is then ticketed with vital information such date of production, a sell date and other details.

The system then assigns the products to different picking areas, and the items are then moved to a designated holding location until the final order picking process. Operators in the picking zones are assigned a specific color on an overhead pick-to-light display. The operators call the orders up as the multicolored digital displays identify a quantity for each item and route. Operators easily spot what needs to go where without the need for a paper list.

“After the trays are checked into the system and are counted, we print the putaway ticket and pack them according to what’s displayed on the overhead monitors,” Wahl says. “There is a designated location for each item. Everything is pulled from the trays, which are stacked below the location by color and code. Then, we case pack automatically and palletize the orders.”

The bakery uses an average of 250,000 lb. of flour each week. “It’s considerable, and flour prices have been a real issue,” Koby Stein explains. “It’s always a gamble these days with commodity prices.”

The plant run three shifts a day, five and a half days a week. “We have no more room here to expand,” Koby Stein observes. “We thought we’d have plenty of room here, but we just keep on growing. We’re hoping to expand next year with an additional plant in Florida.”

With such plans on the drawing board, Masada is positioning itself for the future, and preparing to welcome more customers and consumer demand.