|

| Allan Aasted |

Editor’s note: The following is an excerpt of a presentation to be given by Allan Aasted, ceo of Aasted, at ZDs’s Chocotech 2012 seminar in Cologne, Germany in December.

Over the past 70 years, tempering machines have constantly been improved by making new designs of scraping wings and better water systems.

For the last 10 years the tendency has been to maximize efficiencies by squeezing more chocolate through the machines, which have occasionally been at the expense of the quality of tempering process and the energy consumption.

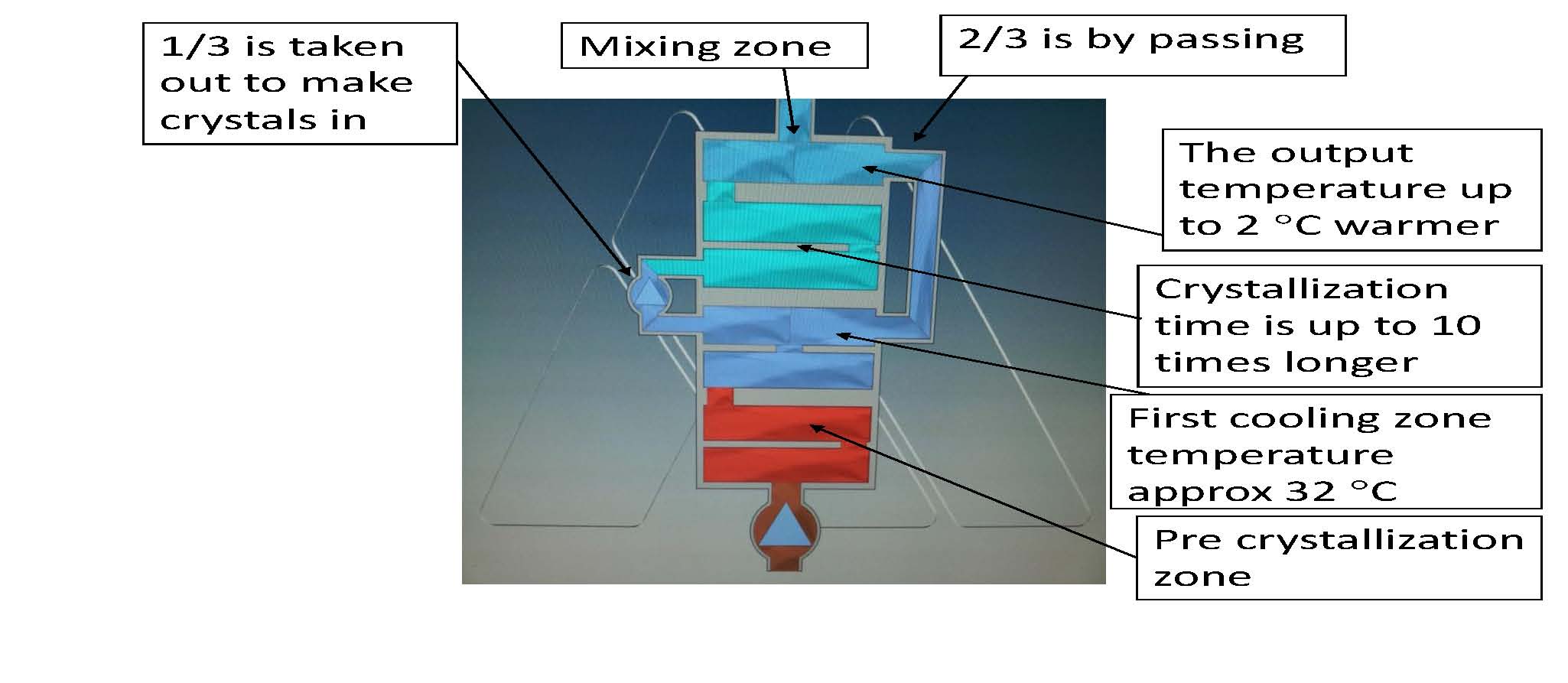

Aasted has broken with this tendency with the new energy tempering technology based on a good, old manual tempering method, and making it into an automatic and continuous process.

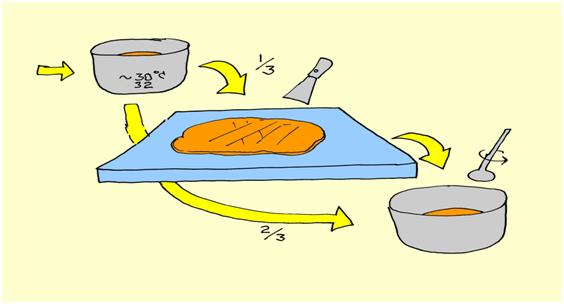

The well known slap tempering method on a marble plate involves using the plate to cool one-third of the mass so that crystallization begins. The remaining two-thirds of the chocolate is then cooled down to about 32°C., at which point the two masses are mixed together.

The tempering process:

The manual method:

|

The image shows the well-known tempering method on a marble plate. The plate is used to cool 1/3 of the mass so that crystalization begins. The other two-thirds of the chocolate is cooled down to approximately 32 degrees celsius.

The automatic and continuous method:

|

The benefits of using the energy technology include:

► Constant tempering degree, which leads to production safety.

► Dense crystal structure for slower fat migration, which leads to a longer time before fat bloom.

► Higher contraction, with results in better demoulding.

► Better gloss, which results in perfect optical quality.

► Low viscosity and yeild value, which has the potential to save CB.

► Less cooling time, which means high throughput.

► Energy savings of at least 50%, and up to 70%, which results in cost savings.

For more information, visit www.aasted.eu.