Palsgaard has started work on a major expansion at its specialist Netherlands factory for high-grade PGPR emulsifiers.

PGPR (polyglycerol polyricinoleate) is a co-emulsifier primarily used in chocolate production to control flow, reduce viscosity, and optimize molding and enrobing. It also reduces fat content in margarine spreads and is a highly effective, plant-based color-dispersing aid that replaces petrol-based waxes in plastics.

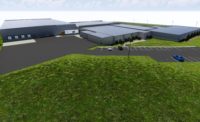

Scheduled for completion in 2024, the €18 million expansion to Palsgaard’s Netherlands plant, which also makes specialty ingredients for margarine and bakery, will double the company’s global capacity to produce PGPR, demand for which is growing by 10% per year.

The facility achieved CO2-neutral production (Scope 1 and 2) status in 2018. The energy-saving design of the new extension includes an additional 1500m2 of solar panels and complete electrification of PGPR production, along with three new reactors and a new downstream processing line. Palsgaard Netherlands Site Director Joris Dhont said: “As well as almost doubling our PGPR capacity to 11500 MT annually, this expansion will substantially increase storage capacity for raw materials and finished goods, which will secure business continuity in times of supply chain disruptions.”

Palsgaard’s new Chief Executive Officer Helle Müller Petersen, who recently joined the company from Arla Foods, led the ground-breaking ceremony on 7th February. She commented: “Visiting our facilities around the world and meeting Palsgaard employees is a priority for my first 100 days as CEO, so seeing work start on the PGPR factory extension in the Netherlands has been a great opportunity to learn more about Palsgaard’s unique DNA.”

Chief Operations Officer Kim Bøjstrup, who also participated in the ceremony, added: “We are already market leaders in PGPR and the world’s only commercial source of fully sustainable emulsifiers. Our expanded Netherlands plant will continue to manufacture the highest quality, palm-free PGPR products.”

Palsgaard is also investing heavily in its main production site in Denmark and is currently installing a new 30,000 MT spray cooling tower. This facility will be supported by the construction of multiple new reaction, distillation, and esterification plants. The €125 million investment will double its production capacity by 2024.