With more than 300 exhibitors, ProSweets Cologne 2018 — the international supplier fair for the sweets and snacks industry — continues to broaden its base, integrating leading players serving the industry alongside smaller and medium-sized companies offering specialized solutions.

This year’s ProSweets Cologne will also underline the significance of the packaging and technology sectors. Together with the Fraunhofer Institute and other designers, Koelnmesse is organizing the “Function meets Design” special event. Acknowledged experts will also address various themes from the packaging section in the lecture program.

Furthermore, ProSweets Cologne’s event program also includes lectures on packing themes in the “Speakers Corner” format. Packing is also a theme on the Expert Stage of the accompanying ISM fair, which is held concurrently to ProSweets. Innova Market Insights will present the current status quo, as well as forward-looking packing solutions to the interested listeners of both trade fairs.

Another theme at ProSweets involves ingredients, which will debut as a special event this year. One trend under scrutiny involves fewer artificial ingredients as well as less sugar and fat, replaced by more natural tastes, colors and alternative sweeteners.

A consumer study by Döhler Sensory & Consumer Science came to the conclusion that more than half of those polled are interested in healthier sweets and snacks, and that they place great value on more than 60 percent of natural ingredients.

Healthy foodstuffs are increasingly positioning themselves on the market on what they don’t contain. Claims such as “sugar-free” and “lactose-free” are beginning to break away from their niche existence and becoming mainstream.

“Brands particularly profit from marketing health and naturalness,” says Julia Büch, food and drink analyst at Mintel. The industry reacts to the preferences of the consumers with recipe adaptions and the development of new products.

One hotbed of new product development involves the search for an alternative for sugar. The ingredients specialists are supporting the industry hereby with functional carbohydrates that are intended to replace the traditional granulated sugar without compromising the quality. Product developers, who implement these with plant fibers, can reduce calories while simultaneously improving mouthfeel, creaminess and texture.

Furthermore, lectures on the theme of “reformulation” are on the agenda at the show’s Speakers Corner again. The DLG (The German Agricultural Society) also plays a leading role here. The aim is to make background information available to the food industry in a way that helps it choose the appropriate sensory and food-technological adaption measures. Given that both the European Commission and the German Federal Government see the reduction of sugar, fat and salt as an important step in sustainably improving the dietary and exercise behavior, such guidance can be invaluable.

All booths highlighted in the following preview are in Hall 10.1

CARLE&MONTANARI-OPM and CMFIMA

Visitors to the booth will discover multimedia devices showcasing the latest developments for the complete range of chocolate processing, moulding, wrapping, primary and secondary packaging equipment.

The chocolate processing segment, which includes machinery from pre-refining to tempering, has been recently expanded with the introduction of the NANO CHOCOLINE, a small line for chocolate preparation that can produce up to 250/300 kg/h. The newest entry is dedicated to small-medium chocolate manufacturers, industrial confectioners and in general, for all those who need to produce small batches with high quality.

On the moulding side, the intermittent and continuous moulding lines range, covering 275, 425, 650, 850, 1,000 and 1,200 mm sizes, has been updated with the introduction of NEXT CAVEMIL, the new intermittent chocolate moulding line featuring a modern design in an aluminum frame drawing on hygienic concepts to facilitate cleaning and maintenance.

The broad range of monostyle and multistyle high-speed wrapping machines from CMFIMA for any kind of chocolate pralines, bars and hollow figures now includes the new S-Pack, an innovative machine for hermetic wrapping of neapolitans and small chocolate bars in an envelope-like wrap with single material plus tear tape for easy opening (up to 400 ppm).

In the primary packaging business, besides the horizontal flow-wrappers JT PRO and JT EVO for chocolate bars, a new dual-lane, horizontal flowrapper — the JT-DualPRO — joins the equipment range. It operates in a smaller footprint (slightly larger than a single flowpack) and allows a double output rate, with just one operator.

For more information, visit www.cm-opm.com; at ProSweets, stop by booth F50-G59

Chocotech

The company will display equipment and provide information on the complete range of candy and chocolate processing equipment at ProSweets. Chocotech offers complete cooking systems for jelly, fondant, caramel, fudge, hard candy, chewy candy, fruit snacks, krokant, bar line kitchens and aeration systems. On the chocolate processing side it offers the Frozenshell line with Pralimat depositing, lentil forming and enrobing.

For customers looking to save energy, the Ecograv is a flexible gravimetric weighing unit with a buffer tank and an integrated continuous dissolver that uses the moisture of the glucose (corn syrup) to dissolve the crystal sugar (or sugar-free ingredient i.e., isomalt) without having to add any or little water, thus greatly reducing energy consumption.

The Ecograv is ideal for hard candies, chewy candies, fondants as well as cooked sugar solutions for bars and allows a dry solids level of up 90 percent to be achieved prior to cooking. This approach substantially reduces the energy required compared to starting the cooking process at 75 – 80 percent dry solids, offering energy savings of 30 to 50 percent. Another advantage of the Ecograv system stems from the flexibility of a gravimetrical weighing system, which enables easy recipe and ingredient changes.

With regards to hard candy processing equipment, the Sucromaster is a hygienically-designed cooking and vacuum system for sugar or sugar-free hard candy. The standard system is designed with a static cooker type Sucrotwist or optionally with a dynamic cooker type Sucrofilm, which is ideal for hard candies that contain milk in the recipe.

Chocotech also supports the IQ, OQ & PQ documentation for pharmaceutical applications.

Information on caramel and chocolate processing equipment will also be available at the booth.

For more information, visit www.chocotech.de; at ProSweets stop by booth B30/C39

Dumoulin

Innovation has always been a trademark at Dumoulin, a force that has led this small bakery machinery business founded in the 1930s to become a market leader in automatic coating technology.

Whether it is about the use of new ingredients, development of new candies, or improvement of machine design, operation and capacity, we at Dumoulin are all focused on one goal: anticipating customers’ expectations.

We have again proved it with the most flexible coating machine one can imagine, a unique and revolutionary piece of equipment that confectioners have always dreamt of. As candy makers know, it is possible to produce sugar-coated goods in a solid pan, but this takes enormous time. On the other hand, a perforated pan does not enable the coating of chocolate. Having an efficient system to produce both types of coated goods sounded a bit like “Mission Impossible.”

Dumoulin, however, managed to pull it off. Our 250-kg batch sugar/sugar-free coating machine can now be equipped with a chocolate coating and varnishing spray arm that — together with drum blinding plates — offers the same process time and quality as a dedicated machine. This innovation meets the demands of small and mid-sized confectioners looking to shift from manual to automatic coating, but doing so within reasonable space and cost constraints.

It also addresses the needs of larger manufacturers’ research and development departments. Not surprisingly, this feature was primarily developed for our own laboratory in order to save space and make sugar and chocolate tests in the same machine. Truly, innovation really lies everywhere.

The LogiC machine will be on display at our booth at ProSweets demonstrating both polishing and varnishing in the same process.

For more information, visit www.dumoulin.com; at ProSweets, stop by booth A10

GEA

The machines presented by the international technology group GEA at ProSweets are characterized by very high production speeds. The GEA Aquarius FlexFormer Extra High Capacity (XHC) is the fastest lollipop former in its class, while the GEA SmartPacker TwinTube C breaks records for confectionery bagging.

Individual lollipop coating is a trend that GEA also pays attention to as well with its Aquarius CoatingLine, the world’s only fully automated line, which forms, cools, coats and wraps lollipops.

By achieving up to 500 pillow bags per minute, the GEA SmartPacker TwinTube C is the fastest machine of its type for confectionery items. It handles products smoothly, so it is excellent for fragile products. The intelligent product-in-seal detection system stops products from being stuck between the sealing jaws, which is a huge benefit with gummy candy.

Being able to produce smaller ‘snacking packs’ at such a high speed, GEA SmartPacker TwinTube C allows confectionery brands to respond quickly to the market trend that consumers are choosing increasingly smaller snack sizes to consume calories more consciously. The machine also performs reliably with long narrow bags, popular for party mixes.

Also being displayed at the booth is the latest execution of the GEA Aquarius FlexFormer lollipop forming machine in the Extra High Capacity (XHC) version. Still a flexible machine, it produces ball lollipops with diameters from 20 to 35 mm. It can produce flavorful lollipops with fillings of gum, chewy candy powders or pastes. The speed is from 1,900 lollipops per minute to 2,770 lollipops per minute depending on the diameter of the lollipop.

For more information, visit www.gea.com; at ProSweets, stop by booth G71

Hamburg Dresdner Maschinenfabriken

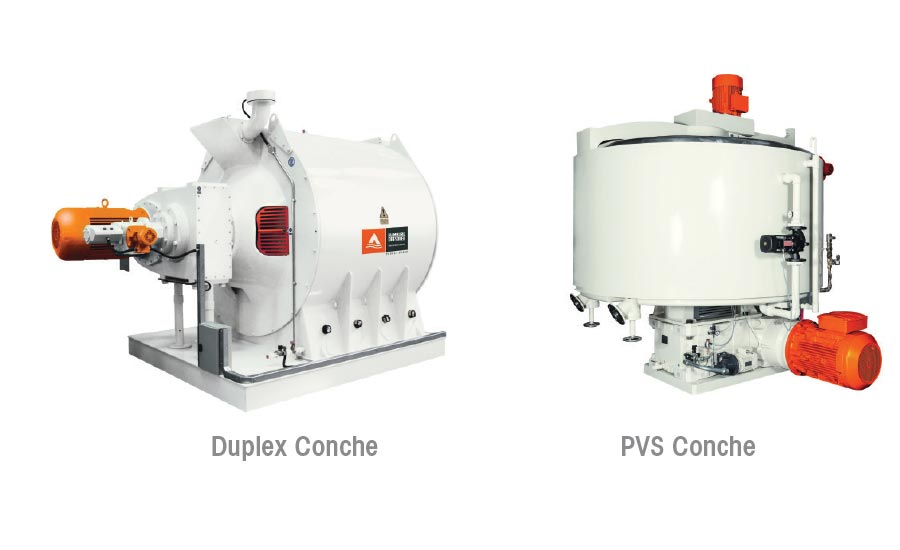

Hamburg Dresdner Maschinenfabriken provides the cocoa and chocolate industry with any technology needed in the value-added chain that begins with the arrival of cocoa beans and continues with the production of chocolate masses, compounds or fillings to precisely meet their global customers’ standards.

The delivery range for cocoa processing includes key components such as winnowing, alkalizing, sterilizing, roasting, grinding, pulverizing and pressing. Both cocoa bean and nib roasting systems are available.

For chocolate production systems, specific equipment designed for dosing, mixing, pre-refining, five-roll refining and conching is available.

For throughputs lower than those economically justifying the use of a conventional five-roll refiner line, Hamburg Dresdner Maschinenfabriken provides its MacIntyre refiner/conche, a technology that enables combining the process steps of mixing, refining and conching in one single machine.

An integrated “Artisan Bean to Chocolate Mass Line” for the production of smaller volumes of high quality chocolate completes the program range.

The Artisan Line consists of a cocoa bean batch roaster, a winnower and a refiner/conche that can not only be used for the production of cocoa liquor but also for making fine chocolate.

All of these technologies can be tested in the company’s new technology center in Dresden.

As a focus topic for ProSweets in Cologne, Hamburg Dresdner Maschinenfabriken will present its various conching technologies. The PVS Conche and the MacIntyre refiner/conche will be displayed at the booth.

For more information, visit www.h-d-m.com; at ProSweets, stop by booth D81

Hebenstreit

Hebenstreit is a global manufacturer of wafer production lines for flat and hollow wafers, as well as state-of-the-art snack extrusion lines. All of the equipment is designed and manufactured in Germany. It also provides a range of fully automated sugar wafer batter preparation systems, which include the feeding and conveying of raw materials.

During Pro Sweets, Hebenstreit will present the largest wafer baking technology available in the market. The wafer sheet size can be up to 1000 x 350 mm, and this represents the next step from the originator of the today’s largest wafer sheet of 700 x 350 mm. In addition, the company is also presenting its state-of-the-art snack extruder SE 70, which also includes the well-known “Turbo” technology.

Given this range of equipment and prowess, it’s evident that many of the worldwide popular wafer and snack products are made with Hebenstreit’s technology and support. To experience “excellent engineering for delicious results,” visit the company’s booth at the show.

For more information, visit www.hebenstreit.com; at ProSweets, stop by booth G41

LoeschPack

At ProSweets, the company will demonstrate its expertise as a system provider for integrated packaging lines for chocolate, chewing gum and confectionery.

The RCB-HS wrapping head machine represents the latest development in the area of hermetically-sealed fold wrapping. This innovative development is ideal for small chocolate products, combining a hermetically-sealed pack style with a traditional fold wrap appearance.

“The RCB-HS packages chocolate bars, tablets and neapolitans in a new and innovative way, giving them a premium look and at the same time ensuring excellent product protection against environmental influences,” explains CEO Thomas Cord. “With top output of up to 600 products per minute, the RCB-HS in this combination is unique in the chocolate sector.”

The machine produces the fold wrap in one wrapping head and hot-seals the pack circumferentially. The heat bars always seal film against film, ensuring extremely tight packaging and preventing damage to the products. Next, folding elements produce the classical fold wrap.

The high-performance F-Series platform for packaging chocolate, wafers and chewing gum in flow packs is another of LoeschPack’s exhibits at ProSweets 2018.

Brief format changeover times of less than 15 minutes and a high cycle rate at top efficiency yield high performance in production halls. Every setting can be precisely reproduced, guaranteeing stable machine operation after a very short time.

For more information, visit www.loeschpack.com; at ProSweets, stop by booth G30/H39

Schubert

Schubert will once again be showcasing its expertise in packaging confectionery and snacks in a wide selection of variants and packaging formats at ProSweets. At the show, the Flowmodul flow-wrapping component, which is seamlessly integrated into a TLM system, will be presented. The innovation has enjoyed great success since its market launch, especially in the confectionery sector.

At its booth, Schubert will use its Flowmodul to demonstrate a flow-wrap packaging component that is seamlessly integrated into a TLM packaging system. In combination with proven robotics and image processing technology, the Flowmodul enables the highly flexible packaging of snacks and confectionery in all types of flowpacks. The end-packaging process into cartons can also be seamlessly connected to the primary packaging process, in a single TLM packaging line.

In Cologne, Schubert will present a picker line with five F4 robots that place sandwich biscuits into the Flowmodul’s product infeed system and which then packs them in flowpacks.

Another focus of the exhibition will be digitalization. In this context, the market leader in digital packaging machines will be presenting its web-based GRIPS.world platform, which will ultimately combine all important functions for monitoring and documenting machine data via a single user interface. By networking the TLM machines via this digital solution, Schubert will be able to continuously monitor machine performance and any deviations from target status —thereby further expanding its preventive service portfolio. The objective is to entirely avoid unplanned machine downtimes.

For more information, visit www.gerhard-schubert.com; at ProSweets stop by booth F30/G31

Sollich

Sollich KG will present numerous innovations at ProSweets.

The worldwide successfully operating Turbotemper e tempering system covers the whole spectrum of chocolate tempering machines for capacities starting at 100 kg per hour and upwards.

On display at the booth will be the Turbotemper e type TE 1800 with a tempering capacity of 1,800 kg per hour. The patented tempering process provides optimum tempering of different types of chocolate, resulting in a constant enrobing quality, a high shelf-life and an attractive gloss of enrobed or moulded products.

The integrated touch panel with intuitive surface and recipe management guarantees easy handling and reproduction of the machine settings. The Tempergraph is designed for online measuring of the degree of temper and ensures a constant product quality.

Besides the well-known Enromat line of enrobing machines with working widths of up to 2,600 mm, visitors will also see the Temperstatic series with belt widths between 820 and 1,300 mm, all of which include integrated tempering.

The Enromat M6-1300 Magnum enrober will be on display, with a belt width of 1,300 mm. The unit allows numerous possibilities for precise adjustment of the product coating.

The Thermo-Flow cooling tunnel section, which features PU-gullwing covers with a drive station, represents the latest standard of high efficiency cooling tunnels that are fully integrated with a high hygiene standard.

For more information, visit www.sollich.com; at ProSweets stop by booth B30/C39

Tanis Confectionery

At its booth at ProSweets, Tanis Confectionery will be exhibiting T-Gel Finishing equipment, consisting of a T-Gel Oiler and a T-Gel Sugar Sander as part of the T-Gel family processing line (for the production of gums and jellies). T-Gel Finishing equipment, after the addition of T-Gel MOULDING starch, represents the last component of the T-Gel family. With this addition to the portfolio, Tanis Confectionery can now provide a turnkey solution for the whole gums and jelly production process — “From concept to finished product.”

Of course, visitors to the booth can learn about all the other Tanis Confectionery processing lines, such as the T-Bar process line that’s designed to produce cereal and nougat bars; the T-Chew, for the production of chewy products; T-Cream for the production of fondants and creams; T-Brown for the production of toffee and caramels; and finally T-Rock for the production of hard candy.

For more information, visit www.tanisconfectionery.eu; at ProSweets, stop by booth B20

Tecno 3

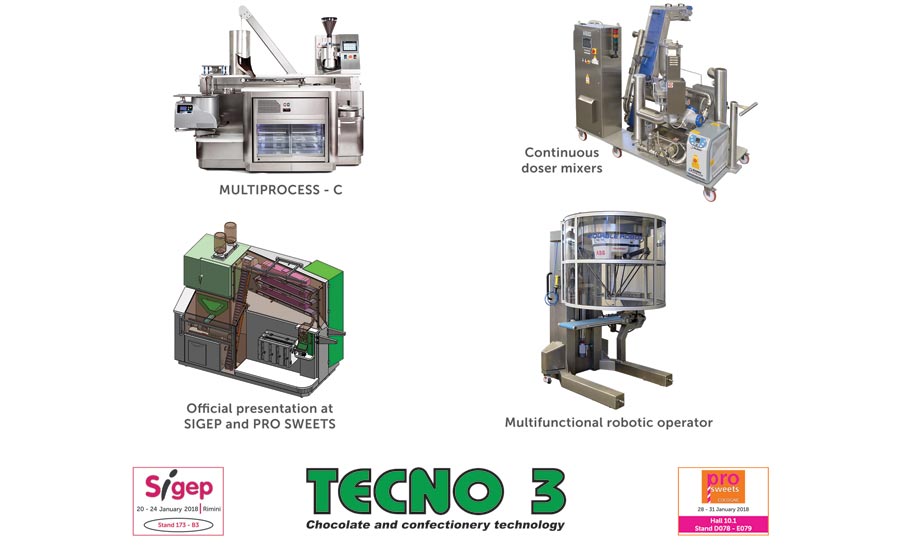

The company will be exhibiting the following machines at ProSweets:

1. The Bean-to-Bar line, which consists of two compact units carrying out all the operations needed for processing the cocoa bean to a finished chocolate:

a) Multiprocess R: This first unit begins with transforming cocoa beans to the nibs stage. The process encompasses roasting, debacterizing and winnowing to separate the shell from the cocoa nib. A hygienic design facilitates easy cleaning thanks to the quick disassembly of all parts.

b) Multiprocess C: The second unit completes the chocolate making process by grinding the nibs to produce the cocoa mass. At this point, the unit mixes, refines and conches the ingredients. The small version (5 Kg.) also comprises chocolate tempering and depositing into the moulds, mould shaking and cooling to produce an end product.

2. MDC: This continuous doser-mixer model is used in the chocolate and creaming process for homogeneous dosing and mixing of liquid and solid ingredients that are called for in the various recipes.

3. ORM: The new ORM robotized station was born to satisfy the needs of automation and flexibility of the most modern production processes. As it is installed upon wheels, it can be easily moved between the various work positions and rapidly connected. It is equipped with a multi-camera vision system for tracking products at inlet-outlet. Being fully customizable, the vision system can also perform product compliance monitoring (shape, color, presence/absence of items, etc.).

For more information, visit www.tecno-3.it; at ProSweets, stop by booth D78/E79

Theegarten-Pactec

The CFW-D from Theegarten-Pactec provides confectionery producers with a packaging machine that overwraps moulded or enrobed chocolate products and wafers with a top performance rate of up to 1,400 products per minute with or without banderole. At the ProSweets booth, one machine will demonstrate the packaging of small chocolate bars in envelope fold with banderole.

The high output rate of the CFW-D is made possible by the dual-track design of the machine. Product tolerances are compensated for with spring-mounted retainer jaws on the packing head. These also ensure that the packaging process is especially smooth, essential for enrobed confectionery in particular. The delivery process is monitored by sensors, which enables optimum control of machine speed in line with the product feed and keeps product backlogs to a minimum.

With Theegarten-Pactec products, machine control via touch panel with intuitive operator interface comes as standard. This makes packaging machine operation a simple matter. The monitor displays important data such as overall plant efficiency, machine states, running times and cleaning and maintenance cycles in simple and comprehensive formats.

Machine performance and fault elimination are further supported and improved through the machinery’s ability to self-diagnose. Direct access to the user manual and spare part catalogue allows operatives to eliminate faults rapidly and avoid unnecessary downtimes. In addition, the machine controls include display of maintenance and cleaning cycles and active notification of necessary servicing and maintenance intervals.

For more information, visit www.theegarten-pactec.com; at ProSweets, stop by booth G20/H29

tna

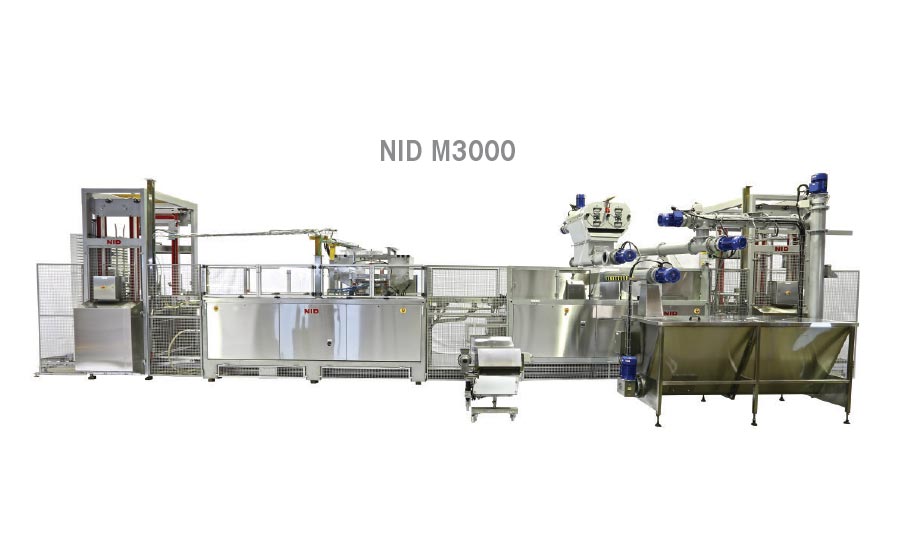

tna, together with confectionery specialist and newest member of the tna family of brands, NID, will highlight its complete range of turnkey solutions for the confectionery industry at ProSweets.

Since the acquisition of NID, tna now offers a complete line of confectionery solutions, from high-speed moguls, starch conditioning systems to oiling and sugar coating solutions, plus the company’s own flexible conveying and high performance packaging technology. Besides on-stand demonstrations of some of tna’s most advanced technology, visitors will be able to find out how NID’s flagship starch mogul can help them achieve higher speeds, greater flexibilities and advanced production efficiencies – all while delivering some of the highest equipment reliability.

One of the most trusted and reliable starch moguls on the market, the NID M3000 is a fully integrated and automated solution, comprising feeder, starch buck, depositor and stacker. The system is ideal to process a multitude of single and multilayer starch-moulded products, including gums, jellies, marshmallows, fondant creams, licorice and crusted liqueur, but also striped and center-in-shell products. The latest version of the NID M3000 now comes with a range of new innovative features, including an automatic starch gate, a modular depositor frame and high-speed turntable demoulding, offering manufacturers some of the highest levels of performance and product versatility.

For more information, visit www.tnasolutions.com; at ProSweets, stop by booth G70

Winkler und Dünnebier Süßwarenmaschinen

Winkler und Dünnebier Süßwarenmaschinen (WDS) will focus on the ConfecECO series presented for the first time in 2016. The ConfecECO line, manufactured for smaller production capacities, has been consistently developed since its market launch. Due to the high demand and the considerable sales success, WDS has extended the modular principle underlying the ConfecECO line and will present the ConfecECO-D model at the show.

The successful ConfecECO machine concept is specially designed for start-up companies or small and medium-sized confectionery manufacturers who want to counteract a high manual and labor-intensive share of production by automatic applications in order to increase their turnover.

In the meantime, the ConfecECO series, initially developed for chocolate products only, has already been supplemented with a variant for pectin, toffee and fondant products, and is constantly evolving. Recently, the so-called Triple-Shot process has become possible for chocolate products as well.

As pectin, toffee and fondant products require a high degree of complexity concerning the depositing into starch moulds, the ConfecECO systems offer the possibility of starchless depositing into silicone moulds. If interested, visitors can find out more about alternative depositing processes at the booth at ProSweets.

With a production capacity of up to 600 kg per hour for chocolate (300 kg/h for pectin, toffee and fondant), depending on the product size, mass and weight, the ConfecECO line provides the ideal solution for the growing demands of ascending companies.

WDS provides full support for companies — from the beginning when acquiring a ConfecECO line to accompanying them during product development and finally finished product — and thereby contributing to their growth. For this purpose, the full range of services of the Innovation and Service Center and the WDS-Product Technology Lab, is available to customers.

For more information, visit www.w-u-d.com; at ProSweets stop by booth B50.