At Prosweets , Chocotech will be exhibiting the following processing equipment at its booth:

Jelly

TheJellymaster is perfect for the efficient production of jelly products. One of the most important factors is consistent viscosity, especially for one-shot products, which are becoming more and more favored in the market place. Also on display is the Jellymix, which is a gravimetric weighing and feeding system to deal with up to eight different colors and flavors. The system can also handle aerated foam, which can be seen in a wide variety of products on the market. Volumetric metering will also be on display.

Energy Efficiency

A large amount of energy is required during cooking to achieve the required final solids, especially for products such as hard candy, chewy candy and fondant. With Chocoech’s gravimetric weighing and dissolving system unit, the Ecograv, the company can now achieve batches of 90% dry solids prior to cooking, resulting in massive energy savings.

Forming

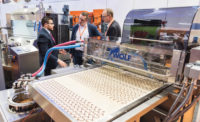

The Chocoform PSL (drop line), engineered for manufacturing chocolate centers such as lentils, balls and eggs, which go on to be panned, will be displayed in its new design. This allows an easy exchange of the drop rolls and thus the product shape , for example, from lentil to egg shape, within 30 minutes.

At ProSweets, visit us at Hall 10.1, booth B020/C029 or go to www.chocotech.de