Food products containing undeclared allergens can result in life-threatening experiences for individuals with food allergies. Each year, more than 30,000 emergency room visits are the result of an allergic reaction to a food. Unfortunately, many of these involve children, the largest segment of the population allergic to some type of food.

Food products containing undeclared allergens can result in life-threatening experiences for individuals with food allergies. Each year, more than 30,000 emergency room visits are the result of an allergic reaction to a food. Unfortunately, many of these involve children, the largest segment of the population allergic to some type of food.In the U.S., more than 90% of food allergies are related to eight allergens: Milk; wheat; soy; eggs; fish; peanuts; tree nuts; and crustaceans. In some individuals, trace amounts of these proteins can trigger an allergic reaction. Each day, their lives depend on the accuracy of the ingredient statements on food packages. Therefore, it’s critical that food manufacturers address food allergens to prevent cross-contamination and ensure product labels accurately identify the appropriate food allergens.

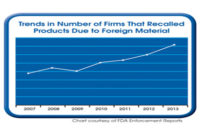

In 2011, the leading cause of food product recalls in the U.S. and Canada was allergens not declared on a product label. Bakery and snack foods topped the list of products recalled because they contained an allergen not declared on the label.

In 2012, this rate of recalls continued. Such recalls often happen due to a combination of factors. Listed below are a few of the most frequent reasons:

- The wrong label on a product. This could be due to the mishandling of leftover labels at the end of a production run, failure of the manufacturer to remove all labels at changeover from one production run to the next, changeover of labeling/packaging film during a production run with the wrong labeling/film or labels that were delivered mixed from the printer.

- The label copy omits the allergen from the ingredient statement.

- A product or ingredient formula(s) change was not reflected in the ingredient statement.

- The wrong ingredient is used in production.

- There is cross-contamination from equipment or utensils.

- Inadequate cleaning failed to remove trace amounts of allergenic materials.

Many of these factors can be mitigated by the following steps:

Step 1: Compare product specifications with the ingredient specifications to make sure they match. Require suppliers to notify you when formulas or ingredient suppliers change. Know your suppliers’ allergen-control programs.

Step 2: Compare product specifications (formula) with the current package label to make sure all allergens are listed on the label. Ensure that obsolete labels or packaging are disposed of promptly and properly. Review newly-printed labels upon receipt to ensure they are complete and accurate.

Step 3: Train receiving personnel to review labels of incoming raw materials for appropriate allergen information.

Step 4: Schedule the production sequence to minimize potential for cross-contamination between products.

Step 5: Review with employees procedures for handling labels at the end of the production run and how partial stacks of labels should be handled to avoid mixups. This is critical, as most allergen-related recalls are due to the wrong product being in the package (the label does not match the product).

Step 6: Ensure the adequacy of cleaning procedures between production runs of allergen-containing products. Since allergens are proteins, effective cleaning procedures require the use of cleaning chemicals to remove allergen residues. Once the cleaning procedure has been completed, conduct a detailed inspection to verify that cleaning has been effective and all allergenic materials have been removed.

Step 7: Train employees on the importance of managing allergens to protect consumers as a way to establish a culture within the operation. Consumers with food allergies will develop a strong loyalty to a brand they feel they can trust.

The culture created by management that’s committed to controlling allergens is essential to minimizing the risk of a recall due to an undeclared allergen.

Author Gale Prince is founder and president of SAGE Food Safety Consultants, LLC, Cincinnati, which offers guidance and solutions to issues such as crisis management, food safety, regulatory compliance and quality assurance.