Graybill Machines

Graybill Machines

Graybill Machines’ Snack Cake Lines produce premium-quality, grab-and-go snack cakes at rates up to 1,000 per min. Manufacturers can load their special ingredients, jellies, creams and toppings; program a topping pattern; and watch the lines swiftly and precisely slice, separate, inject, ice and assemble snack cakes ready for further cooling or packaging. The machinery is constructed with rugged, welded, tubular stainless-steel frames for stability and has stainless-steel area-skirting. Polycarbonate safety guards protect operators and products.

717-626-5221 • www.graybillmachines.com

Hinds-Bock Corp.

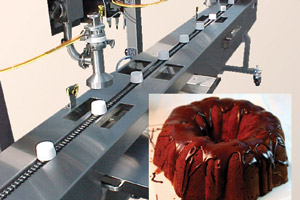

Hinds-Bock Corp.’s new ring/bundt cake line produces multiple flavors or swirl patterns and applies various toppings, such as nuts or streusel. Manufactured in single or dual lanes, the line is available with single- and dual-piston batter depositors capable of depositing many flavors of batter into a pan at different stages down the line. Divided hoppers also allow each piston on a dual-piston depositor to run a different flavor. Specially designed 360-deg., custom-ring, positive cutoff spouts on the depositors deposit batter around the ring-cake pan, while keeping it off the center cone. The line offers optional swirling devices that can automatically swirl two types of products, such as batter and fruit, in 360-deg. pans. Targeted dry topping units for streusel or nuts can be added to the line, as can a custom Hinds-Bock moist streusel targeted topper.

877-292-5715 • www.hinds-bock.com

CEM Corp.

The FAST Trac Analyzer from CEM Corp. uses a patent-pending technique to provide fast, accurate results in snack foods, dairy powders and other dry ingredients. A second-generation Nuclear Magnetic Resonance (NMR) system, FAST Trac features two new patent-pending capabilities: Interference-Free Moisture (IFM) technology, which allows the system to accurately determine moisture over a broad fat content range; and QuikPrep, a rapid sample conditioning feature that enables the system to complete a test in only 2 min. FAST Trac also has an intuitive, easy-to-use touch screen interface and can be used with CEM’s SMART Turbo System for moisture and fat analysis on both wet and dry samples.

704-821-7015 • www.cem.com

Demountable Concepts Inc.

Refrigerated and freezer versions of Demountable Concepts Inc.’s Warehouse on Wheels (WOW) System are now available. With the system, preloaded, refrigerator or freezer straight-truck bodies are line-hauled in multiples via semitrailer to regional markets. The bodies are demounted in a drop yard and stand on retractable legs. Locally domiciled straight-trucks mount individual bodies for their routes and immediately begin their deliveries. The trailer driver mounts the empty bodies from the previous day and returns them to a distribution center for reloading. The system components consist of specialized semitrailers that can mount and demount multiple straight-truck bodies; straight-truck chassis equipped with a hydraulic lift and locking system to facilitate mounting and demounting bodies; and straight-truck bodies with a unique base frame and integrated retractable legs. Each body is built to customer specifications.

800-254-3643 • www.demount.com

Patty Paper Inc.

Patty Paper Inc. offers a wide variety of papers approved by the Food and Drug Administration (FDA) for use in the food industry, including those for bakery products and snacks. According to the company, it differentiates itself from many other paper manufacturers by using a patented, FDA-approved, paper packaging system to wrap each stack of paper it sells. The individual, fully wrapped packages keep each stack of interleaving paper clean and sanitary until it is used. Sheets are protected from environmentally introduced contamination with the company’s safe outer wrap.

800-782-1703 • www.pattypaper.com

Heat and Control Inc.

Heat and Control’s Modular Dust Collection (MDC) unit enables food producers to eliminate a variety of manufacturing problems caused by airborne seasoning dust. According to the company, the unit costs about 40% less than whole-room dust-collection systems and can cut energy usage in half. Integrated into each FastBack Revolution on-machine seasoning station, the compact unit collects dust at the point of application and requires no hood or bracket over the product area. MDC retrofit packages are also available for most existing Revolution OMS applicators.

800-227-5980 • www.heatandcontrol.com

VAC-U-MAX

The MDL650 continuous-duty vacuum from VAC-U-MAX uses a continuous bagging system and eliminates drum handling, giving operators better control over dust. The model comes equipped with a filter cleaner that doesn’t require compressed air and the filters can be cleaned without shutting off the unit. While the filters are being cleaned, the discharge valve opens and automatically discharges the collected product into the continuous bagging system.

800-822-8629 • www.vac-u-max.com

Unifiller Systems Inc.

Unifiller Systems Inc.

The iSpot depositor from Unifiller Systems allows users to draw and portion smooth, flowable products (batter, fillings, mousse, icing, sauces and more) directly from bowl or pail and deposit them directly into tins and pans and onto products at up to 150 deposits a min., depending on portion size and product consistency. The unit comes with a 1-in., hand-held nozzle and a 5-ft.-long, food-grade sanitary hose that takes all standard bakery tips. Compact, portable and easy to use, iSpot fits containers up to 23-in. deep. An optional pail shelf keeps containers off the floor.

888-733-8444 • www.unifiller.com

ACS Valves

Designed specifically for rugged applications generating harsh or abrasive dusts, the CI Series of rotary valves from ACS Valves is available in cast iron or 304 or 316 stainless-steel and in sizes from 10-44 in. Rotor configurations include closed-end, metering, shallow-pocket, Teflon-coated and adjustable-tip. Adjustable rotor tips are available in EPDM (ethylene propylene diene monomer), hardened steel, stainless-steel, bronze or polyurethane. Interior surface coating options include hard chrome, tungsten and Teflon. According to the company, the series’ bearing design easily manages applications with pressure differentials up to 15 lb. per sq. in. (PSIG) and protects the bearings in high-temperature applications to 750 deg. F.

800-655-3447 • www.acsvalves.com

Spraying Systems Co.

Spraying Systems Co.’s expanded MFP (Maximum Free Passage) FullJet full cone nozzle line now includes 1.5 in., 2 in., 2.5 in. and 3 in. sizes for applications with flow rates up to 705 gallons per minute (gpm) and 80 lb. per sq. in. (six bar). All are available in 316 stainless steel; sizes up to 1¼ in. are also available with brass bodies. According to the company, MFP FullJet nozzles feature a unique vane design and the free passage of particles 30-75% larger than those allowed by standard full cone nozzles. They are suitable for any application affected by clogging problems due to re-circulated liquids or debris, including food processing, washdown, dust suppression and waste water aeration.

630-665-5000 • www.spray.com

The Witte Co. Inc.

Vibrating screeners from The Witte Co. permit fast, easy and full access to loading trays, screening areas and pans to allow frequent, thorough cleaning and speed product changeover, while minimizing line downtime. Able to screen virtually any dry, granular, free-flowing and non-free flowing products without clogging, Witte screeners are available with a choice of wire-mesh or perforated screens in standard widths of 10, 23, 35 and 47 in. and in custom sizes. To meet Food and Drug Administration (FDA) requirements for sanitary processing, the screening system is also available in 100% stainless steel with continuously welded and polished seams.

908-689-6500 • www.witte.com

![]()

Flexicon Corp.

The AA-0985 mobile bulk bag filling system from Flexicon Corp. features a patented Twin-Centerpostbulk bag filler with a metal detector/separator and a tilt-down conveyor/feeder with a clog-free, dust-containment system. The system detects metal in the freefall stream of material entering the filler and ejects it through a chute that discharges into a removable drum. It also features a fill-head height adjustment to accommodate popular bag sizes; an inflatable cuff to seal the bag inlet spout; a blower to remove bag creases prior to filling; loadcells for filling by weight; a vent port for dust-free air displacement during filling; pneumatically retractable bag hooks; and an automated vibratory densification/de-aeration system to maximize capacity and stabilize the bag for storage or shipment. In addition, the unit is constructed of 316 stainless steel, finished to sanitary standards and configured with full-length forklifting tubes.

888-353-9426 • www.flexicon.com