Flexibility is now a requisite for bagging equipment. As consumer food-packaging needs change, bakers and snack producers must be able to quickly adapt, so purchasing a machine that only makes one type of bag is no longer an option.

Automated systems capable of running higher payloads at higher speeds are important to bakers and snack producers, too, especially to those with high-volume customers, such as big box and club store retailers. In response, bagging equipment manufacturers are offering systems that focus on automation and system integration.

Prevailing trends

John Panaseny, CEO, Rovema North America, Norcross, GA, sees several significant trends impacting the baking and snack markets. The first trend is a move from bag-in-box packaging to flexible standalone bags, which is being driven by cost savings and environmental sustainability efforts. The second trend is growing demand for a universal bagger, specifically one capable of handling many bag styles—pillow, gusseted, flat-bottom and stand-up doy-style pouches, with or without a reclosure feature.

Integrating the line is also a goal these days. “There continues to be great interest and emphasis on system integration,” says Panaseny. “This trend is tied to a reduction in customer engineering staffs, as well as improved project timelines and better startup efficiencies (vertical startups). The goal is to have the entire packaging line integrated, tested and installed by a single source of supply.”

Rovema North America recently introduced the B-Series bagger, which integrates its latest design elements—high flexibility via servo-driven seal jaws to produce a variety of bags and a new frame design that facilitates cleaning. In addition, the company now offers baggers with design elements geared to specific markets, such as the BVR line for the bakery and snack industries.

As the U.S. distributor for German equipment manufacturer GHD Georg Hartmann Maschinenbau GmbH, Lawrence Equipment Inc., South El Monte, CA, focuses on bread, bun and flatbread bagging and bag-closing systems. In these areas, Hartmann, with development help from the team at Lawrence Equipment, has made important improvements in flatbread bagging and sealing in the last two years, notes Glenn Shelton, vice president. “Today, premade zip-lock bags are required for almost 90 percent of retail flour tortillas and wraps. Buyers expect the bag’s seal to be parallel to the bag’s zip-lock top and neatly trimmed. Our VS320 Multi Servo Impulse Sealer yields all of the above with only one operator.”

The SVE 2520 DZ vertical bagger from Bosch Packaging Technology, New Richmond, WI, is designed for food processors looking to drive visibility and consumer preference at the point-of-sale. The machine offers seven bag styles: pillow, gusseted, block bottom, corner seal, full corner, three-sided and doy, with various reclosure options, including zippers. Flexibility is further enhanced as changeover from pillow to doy zip takes 45 minutes. The bagger’s continuous-motion operation is coupled with a zipper applicator to enable high-speed production and a lower cost-per-bag for increased return on investment.

Bulking up

Spiroflow Systems Inc., Monroe, NC, has been focusing its efforts on semiautomated, bulk bag filling systems and end-of-line robotics. “Control systems are complex, and customers may be filling bulk bags, gaylord boxes or other interchangeable bulk containers,” says Carolynn Sarver, director of marketing. “Our customers consistently require custom design elements, which is what we provide.” This may include a telescoping fill nozzle, box-top tamping and/or integration of other components, such as take-off conveyors, pallet dispensers, slip sheet dispensers, turntables and stretch wrappers.

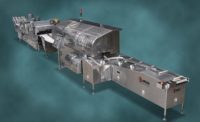

Pacepacker Services, Essex, England, recently unveiled the FastPac high-speed bulk bagging line, which includes a sack placer with a top speed of 16 to 17 bags per minute, 20 percent faster than previous models. “When taking flat bags from a stack and positioning them for filling, conventional machines use suction cups to pick up the bags,” explains Paul Wilkison, business development manager. “This method limits the use of porous bag materials. The FastPac sack placer uses mechanical grippers to handle porous materials, in addition to paper and plastics.”

FastPac machines pick up sacks by the bottom and peel them off the stack, which eliminates bags sticking together. To ensure that the pace of production is not compromised, Pacemaker has enhanced its Total Bag Control system, which holds bags firmly in place through the filling and sealing process to match the higher speeds of FastPac sack placers.

Other considerations

Machine footprint is another growing concern for bakers and snack producers with limited floor space, notes Eric Aasen, product manager, Bosch Packaging Technology. “As machines incorporate additional features and benefits, the size often grows to reflect that,” he says. “Bakers and snack food producers are looking for bagging machines with a smaller footprint that offer easy integration into existing lines. To meet that need, Bosch developed vertical form/fill/seal bagging technologies, such as the SVE 2520 DZ, which offers 50 percent higher output, while taking up one-third of floor space.”

Sarver says Spiroflow works with food processors of every size and has seen a widespread focus on further protecting the public from foodborne pathogens and illnesses. Bagging equipment, as well as other upstream and downstream equipment in the processing line, is an integral part of bakers’ and snack manufacturers’ efforts to deliver safe and fresh products to consumers.

In addition, Sarver sees several consumer trends that will likely continue to impact manufacturers’ bagging system purchases. “Consumers are driving demand for individual portions and green packaging,” she says. “As a result, we see food processors setting up redundant processing lines to deliver, for example, peanut- or gluten-free products.”

As consumers and retailers continue to expect more from food packaging in terms of product safety, freshness, usability and portability, bakers and snack producers will, in turn, demand more from their bagging equipment. For equipment manufacturers, bagging systems with inherent flexibility will be the key to satisfying everyone.