When it comes to packaging materials, one of the biggest consumer demands cited by bakers and snack producers is the need for extended shelf life—packaging that makes food last longer on the store shelf and in the refrigerator. Demand for resealable, single-serve, lightweight packaging is strong, as well.

Consumers demand convenience while retailers request lightweight options that cube well on the shelf and extend product life. These needs translate into greater demand for flexible, lightweight packaging sized for personalized grab-and-go convenience that merchandise well across multiple formats—brick-and-mortar or e-commerce.

“In the bakery/snack food market, there has been a trend from rigid to flexible packaging, especially into stand-up resealable pouches. Pillow pouches also are popular due to low cost and the production efficiencies of this style. Pre-zippered film is still growing in this market,” says Art Malcomson, director of sales and marketing, Zip-Pak, an ITW Company, Manteno, IL.

Busy, on-the-go consumers value freshness, convenience and portability. Consequently, marketers are looking for packaging opportunities to meet those needs. “Resealable pouches extend the shelf life of foods and allow for successful containment while on-the-go. Sustainability and the desire to lower costs are driving the change from rigid to flexible packaging, as well,” Malcomson adds.

Consumers also want more information about what they are buying, where it comes from, what it contains and even how long it took to get to the retailer. All these factors are relevant, especially in the healthy, better-for-you snack market.

As consumers continue to utilize e-commerce for their food products, manufacturers will need packaging solutions that better handle distribution demands. “I envision that producers will seek out key functional requirements: barriers to moisture, vapor, oxygen and odor, and tamper evidence to ensure the consumers’ experience with the brand/product is maximized,” says James Foster, senior marketing manager, Clear Lam Packaging Inc., Elk Grove Village, IL.

Barriers provide freshness

“Barrier” is a word used often when discussing new developments in packaging materials. Bakery products have traditionally been packaged in lower-barrier flexible materials, according to Richard Barrett, regional manager, U.S. sales, MOCON, Minneapolis. “Typically, these products have shorter, two- or three-day shelf lives. With such minimal requirements, there hasn’t been a need to spend more money on packaging materials or processes to extend that shelf life.”

But forward-trending product formats are dictating change. “New products types have begun to push the barrier envelope,” says Barrett. “For example, gluten-free products are on a growth trajectory, as well as bakery products positioned as ‘natural’ or ‘preservative-free.’ Without additives that are traditionally found in many baked goods, these products are unable to achieve desired shelf life objectives.”

Barrett says the solution lies in selecting packaging materials with higher barriers and processes, including modified-atmosphere packaging (MAP), to help extend shelf life. Several snack items, including higher-priced, premium nut products, also are affected. “With these trends firmly in place, we expect more advanced barrier materials and MAP to gain a stronger foothold in the bakery/snack market.”

MAP, which extends shelf life by replacing oxygen with an inert gas, is used throughout the food processing industry. In fact, Clear Lam Packaging Inc. has implemented packaging solutions that utilize MAP technology worldwide. “MAP is still a robust and vital tool used today and will be well into the future,” says Foster.

Sealed Air, Charlotte, NC, has introduced Cryovac Freshness Plus active packaging technologies, which are engineered to extend shelf life, maximize flavor and product color, and reduce confinement odors—all through packaging. It protects against light-catalyzed oxidation so products can be displayed in clear packages. Also, its polymer is invisible to metal detectors, which allows processors to use metal detection systems after the packaging operation. The Cryovac barrier can extend shelf life from eight days to 30 or 40 days, according to Kari Dawson-Ekeland, director of marketing.

Intelligent packaging

Some packaging options are more price-friendly than others. “Because of the low unit cost of most baked goods, it is not economical to apply some forms of intelligent packaging to individual packs, unless it is a QR code, which is already being used in the confectionery sector for promotional campaigns and consumer engagement,” says Andrew Manly, communications director, Active & Intelligent Packaging Industry Association (AIPIA), Reston, VA. The most high-profile of these is the Nestlé campaign that encourages people to “Take a Break, Have a Kit Kat,” encouraging the consumer to scan a QR code to access videos.

Manly notes that one use of intelligent packaging involves monitoring product quality. “The next step may be to delete the arbitrary ‘sell by’ or ‘use by’ information and add a condition monitor onto the pack that tells the consumer—and retailer—what is really happening to the product. Condition monitors can function after the pack is opened to tell the purchaser if the product is still fit to consume.”

New packaging materials can create a multi-sensory experience for consumers. For example, Zip-Pak Sensus is a closure technology that is part of Zip-Pak’s family of Sensory Feedback Fasteners. It informs the user through tactile and audible cues when the closure is securely fastened, assuring that food products stay as fresh as possible after purchase. “A recent addition to the category is Fragrance-Zip, a reclosure that emits a customized, attractive aroma when the package is opened,” Malcomson says.

Think green

The latest packaging materials are designed to accommodate food-safety regulations and sustainability initiatives, as well. Through collaboration with the Sustainable Packaging Coalition and other industry partners, Dow Chemical Co. has developed Recycle Ready, a system that allows manufacturers to create flexible packaging that can be easily recycled through existing polyethylene film recycle streams, such as grocery store drop-off programs.

These flexible pouches incorporate multiple layers, but use only one basic type of raw material, polyethylene. For packaging that requires barrier film, such as pouches containing granola or snacks with fruit or nuts, those made with RETAIN polymer modifiers can be recycled in polyethylene streams.

“This technology is a breakthrough in packaging design for recyclability. It possesses the properties of a multi-layer pouch, but behaves like a pure polyethylene bag in the recycling stream,” says Kelly Cramer, project manager, Sustainable Packaging Coalition, Charlottesville, VA.

General Mills recently created new packaging for its Totinos pizzas. The packaging went from a traditional box format with the pizza in clear wrap to a flow-wrapper style of packaging. In order to make the switch, the pizza was reformulated from a round shape to a rectangle.

“We made this packaging change to provide additional benefits to consumers,” says Mike Siemienas, spokesperson, General Mills, Minneapolis. “It is now toaster oven-compatible; you can easily fit two pizzas on a baking tray. It is easier to cut, the packaging is easier to open, and it takes up less room in the freezer and creates less waste.”

From an environmental standpoint, General Mills made the move to save space for consumers in their freezers and to produce less waste in the manufacturing process. In addition, the new packaging allows the company to fit more pizzas in a case, which increases transportation efficiency when shipping the product to stores.

Club store channel

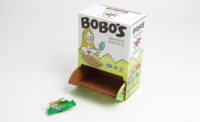

New packaging is being designed to accommodate needs of the warehouse/club store channel, a rapidly growing market. For example, PaperWorks Industries Inc. has developed a new club store package that features an outer carton made from 100 percent coated recycled paperboard and an internal liner made with paper-based material to address specific snack food needs. The liner material adds strength to the overall structure.

“The result is a crush-resistant package that offers similar performance attributes to corrugated—such as strength, rigidity and stackability—but with the high-quality graphics appeal of a folding carton,” says Karl Broderick, vice president of sales and marketing, PaperWorks Industries Inc., Bala Cynwyd, PA.

The reinforced carton structure can support holograms, film laminations, foil stamping and high-gloss coatings. Metallic and other specialty inks can be used to heighten visual appeal. Because the warehouse/club store pack is not fluted, there is no washboard printing effect, leaving behind only the detailed graphics.

3M Industrial Adhesives and Tapes Division offers Scotch Multipack Tape, a printable clean removable tape that is used as an alternative to shrink wrap, bags and chipboard for bundling products. By combining Scotch Multipack Tape with 3M Carry Handles, 3M has developed a solution for companies that need to bundle pouches for sale in warehouse/club stores.

This solution offers shelf presence and sustainability benefits on the retail end. The printable tape and carry handles enable manufacturers to stand out and offer convenience to consumers. It also cuts energy consumption by up to 96 percent and uses 50 percent less packaging by weight.

“Eco friendly products and the green movement are definitely trends that are pushing manufacturers to produce bio-degradable or dual-purpose packaging, as well as packaging that is easier for the consumer to recycle and use for multi-purposes,” says Joey Benadretti, president, SYSPRO USA, Costa Mesa, CA. “Bio-derived and bio-degradable technologies within packaging will become much more prominent in the near future.”