Snack producers and bakeries can travel multiple avenues toward improved operational efficiency. Additional automation is a natural progression. New strategies centered on software-based, paperless logistics—from supply-chain management through streamlining warehouse tasks and delivery—also bring valuable benefits to any operation. And preventative maintenance is instrumental to success.

But efficiency is also a mindset. It’s training a critical eye on every aspect of a business to fine-tune each touchpoint, building in strategies related to lean manufacturing, all with the goal of getting the most out of every financial input for the system.

A lean machine

More operations today include some method of continual measurement and evaluation related to line and overall facility performance. It’s a way to isolate points in the system that require improvement, an instrumental aspect of lean manufacturing.

“Lean manufacturing is a distinct, continuous improvement initiative, bearing little resemblance to traditional managed environments,” says Dwayne Hughes, senior vice president, Hearthside Food Solutions, Downers Grove, IL. “At its core is a culture of waste elimination through and across all of the various value streams within, and a focus on customer satisfaction.” He notes that anything without value that is adding work to the system should be eliminated with a set of disciplined tools and practices, such as value stream mapping, 5S (sort, set in order, shine, standardize and sustain), kaizen events, PDCA cycles (plan-do-check-act/adjust), kanban and poka-yoke (“mistake-proofing”).

“There are also unique differences in leadership roles, such as a team model with key stakeholders identified, a much-flatter cross-functional organizational structure and an information environment that is transparent, with highly visual and focused on key performance indicators (KPIs) and employee-management relations,” says Hughes. “For example, error reporting is valued as an opportunity for everyone to learn; employees are encouraged to take ownership of their job responsibilities and to initiate improvements.” This helps streamline manufacturing, improving the processes and maximizing customer value. This focuses the system on efficiency, quality and—ultimately—customer satisfaction.

“By improving velocity and reducing waste, you increase processing line efficiency,” says Hughes. “Identify your slowest capable machinery—the choke point. Now improve its capabilities via redesign or capital replacement. Next, identify all the loss points in your process—leak points. As you eliminate these losses, more inputs will become outputs, increasing efficiencies.”

Technological solutions

Inefficient ovens are a significant source of wasted energy—and capital—across the snack and bakery industries. “There are many reasons bakeries may be using inefficient ovens,” says David Emerson, product manager, Spooner, Ilkley, England. “The initial oven design, concept and construction may not have been developed with efficiency in mind. Different ways of heat transfer result in heat loss. Features such as too many doors for access and hygiene can also result in heat loss, which in turn drives up the energy costs.”

Emerson supports forced convection as the most-efficient method to operate an oven: “Forced convection technology is the most-efficient way of transmitting heat, giving a faster, even bake with minimal flash heat.” He also notes that increased production rates do not necessarily require higher system inputs. “Throughput can be increased with reduced energy consumption,” he says.

When in the market to replace ovens, look for features like integrated terminal ends to prevent heat loss, internal walkways for access and hygiene, automated baking, energy-efficiency modes, rapid start-up and shut-down times, invertors, and heat-recovery systems, suggests Emerson.

“Although technological progress has now automated the majority of snack manufacturing processes, labor costs still account for the biggest share of the budget in many facilities,” says Chris Jones, group product manager, controls, tna, Birmingham, England. “Despite this, a lot of manufacturers are still reluctant to automate processes that are currently carried out by human hands as they fear that this may change their product’s features. However, in many plants, efficient work processes are not always easy when outdated procedures prevail, and a lot snack manufacturers waste production uptime with maintenance and repair work, while in other plants, staff are often engaged in repetitive tasks that could be more accurately performed by a machine. Automating some of these processes can significantly reduce human error and free up time for staff to focus on more-challenging tasks.”

By conducting an analysis of current facility variables, utilizing lean manufacturing tactics, operations can better determine which tasks would see improvement through automation. This frees personnel to carry out jobs more tailored to their particular skill set, notes Jones.

“Efficiency can also be improved by pairing an existing programmable logic controller (PLC) system with a concise and clear human-machine interface (HMI),” says Jones. “This will detect faults much quicker than the human eye and allow operators to react to faults immediately, minimizing downtime and waste.”

Jones notes that improvements to plant efficiency can lead to safer, higher-quality snacks and baked goods. “By improving traceability throughout the entire production chain, automation has provided operators with much more control over product quality and food safety,” he says. “Nowadays, control systems collect and evaluate highly detailed and reliable data from as many parts of the production process as possible. As a result, faulty products are detected and removed from the production line quickly and efficiently, well before they can cause any harm to consumer or the brand. Improved control systems also allow for consistency of production and make it possible for irregular system performance to be quickly spotted and corrected.”

Many bakers crafting artisan products strive to strike a balance between efficient automation and hand-on expertise. “Automation has traditionally always been about repeatability and product continuity and uniformity,” says Jones. “However, as the demand for artisan products rises, a lot of manufacturers are starting to look at ways to automate their processes to keep up with the demand. The great thing about controls technology is that you’re able to configure it so it meets your exact requirements. Most controls systems will let you adjust the settings, so that processes can be consistently randomized. While this may not be an exact imitation of the processes carried out by human hands, it may allow manufacturers to achieve some of the distinct properties of artisan products. In general, processes with tighter performance and control can produce a more-consistent artisan product.”

Technological improvements also extend to logistics solutions like enterprise resource planning (ERP) and SAP software solutions. “We view the value chain holistically and consider these solutions to be vital and integrated,” says Hughes. “We are an integrated SAP environment. As a contract manufacturer, we use that platform and other technologies to integrate with customer and vendor supply chains, creating as seamless a flow as possible of information, materials and commerce.”

Keeping the system humming

Maintenance dynamics related to snack and bakery lines factor decisively into operational efficiency—and preventative measures can do much to keep a finely tuned system humming.

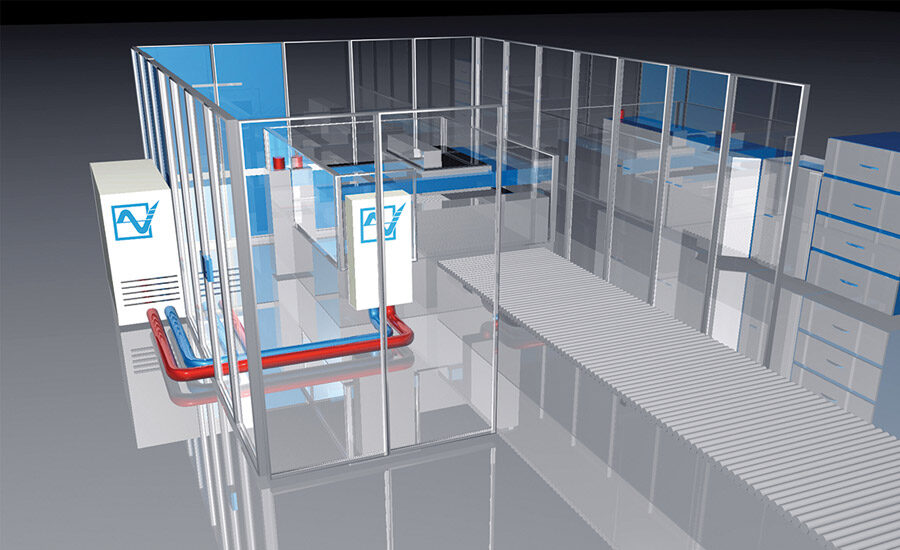

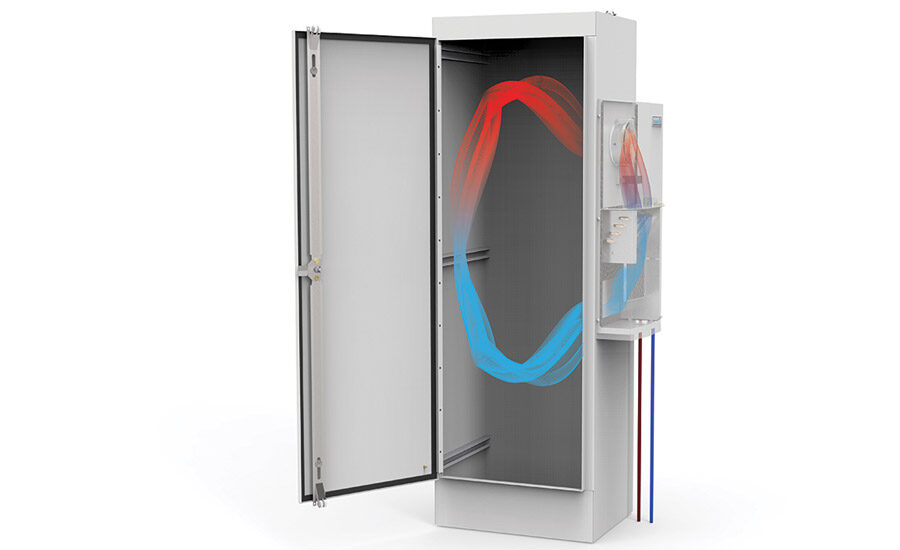

“In commercial bakery and snack production facilities, high-performance electrical components critical to the daily production process are housed within metal enclosures,” says Allison Kowalewski, industry group specialist, food and beverage, Pfannenberg, Lancaster, NY. “These critical electrical components are placed in metal enclosures to protect personnel from possible electrical shock and to protect the electronics from flour dust, water and other ambient conditions.”

Such components also generate a significant amount of heat—a situation that requires mitigation. “Too much heat leads to a significantly reduced electrical component life expectancy and eventual shutdown of systems, resulting in expensive replacement costs, downtime and loss of revenue,” says Kowalewski.

One approach is using air/water heat exchangers. “These cooling units mount onto an enclosure just like an air conditioner, but instead of using refrigerant to cool, they can use the already existing cool water/glycol source to provide cooling,” says Kowalewski. “Additionally, they use a fraction of the energy used by an air conditioner to save the production facility money, have a longer life span and require little to no maintenance.”

Typical hot spots in snack and bakery facilities include make-up areas, such as for dough preparation, and the areas housing ovens. Kowalewski notes that, for electronics, the cooling “sweet spot” is 85–95°F. “Anything higher than 95°F can cause heat stress failure on the equipment,” she says.

“Environmental simulations can be done in a climatic chamber, infrared measurements can be taken on site or CF design software can be used to provide an accurate computer simulation of what is required, based on real-world components and simulated airflow,” says Kowalewski.

Another area related to preventative maintenance is lubrication. “The operating environment of a snack or baking facility can have a challenging effect on the performance of a lubricant,” says Toby Porter, food market manager, Klüber Lubrication, Londonderry, NH. “For instance, high levels of humidity and increasing temperatures can work against both the surface protection and long life that even some specialty lubricants can provide. What this means is that the facility may be lubricating more often than necessary, or perhaps isn’t getting the longest life possible from components, leading to increased downtime for maintenance and lower levels of efficiency.”

Food safety and other measures have impacted the types of lubricants favored these days. “Calcium sulfonate complex thickeners have become more prevalent, as they can have unique performance characteristics,” says Porter. “Depending on the application, these thickeners can have an improved load-carrying ability and performance in the presence of water.”

The most-important food-safety factor related to food-grade lubricants is potential contamination of the food product, notes Porter. OEMs will also provide machinery specifications that require consideration.

“It’s important to understand the risk level associated with the application point so that a decision can be made on the type of lubricant that should be used, the type of safety registration that is appropriate and how that lubricant will be stored and used properly,” explains Porter.

It’s also essential to observe ongoing performance. “Understanding the overall tribological environment is extremely important, as changes in factors such as temperature, load, speed, outside media, etc. can have a significant impact on the surface protection a lubricant provides,” says Porter. An increase in chain temperature, for examples, can lead to a higher oil evaporation rate and the necessity for either a change to the application method, or possibly a different type of food-grade base oil, in order to provide optimum protection, he notes.

They myriad variables at play in food production pose continual challenges: attracting qualified employees, rapidly changing technologies, ever-evolving consumer preferences that dictating changes to products and packaging. Improving plant efficiency is an ongoing challenge.

In the end, we all want to run faster and more efficiently while maintaining peak product quality. And a line running at peak operational efficiency is a beautiful sight to behold.