Equipment

Topics

Control Systems

Depositors, Dividers & Rounders

Extruders

Fryers

Laminators & Sheeters

Mixers

Ovens & Proofers

Packaging

Slicing, Cutting & Portioning

Warehouse & Distribution

Inspection & Detection

ARTICLES

Gericke launches Feedos M bulk material feeder

Eriez expands Salient Pole Rare Earth line

Bradman Lake secures equipment spot at Diamond Bakery

WeighPack debuts bulk weigh filling machine

GEA offers preassembled modules for ovens

Puffed and extruded snacks shaped by innovation: Clextral

Slicing and portioning equipment must offer efficiency, sanitation

Piab Robotic Gripping Division moves to Fairborn, OH

Consistency is key with seasoning and coating equipment

Grote Company acquires conveyor manufacturer ProFab

Douglas J. Peckenpaugh

Douglas J. Peckenpaugh is Group Publisher of Snack Food & Wholesale Bakery, Dairy Foods, The National Provisioner, and Packaging Strategies for BNP Media. He has nearly three decades of publishing experience following the food industry from farm to fork, covering agriculture, ingredient processing, retail grocery branding, foodservice menu development, and food product R&D and manufacturing. He serves in leadership roles at his local suburban Chicago food pantry and church. Doug studied Professional and Creative Writing at Purdue University.

IMAGE GALLERIES

New Processing Equipment: February 2023

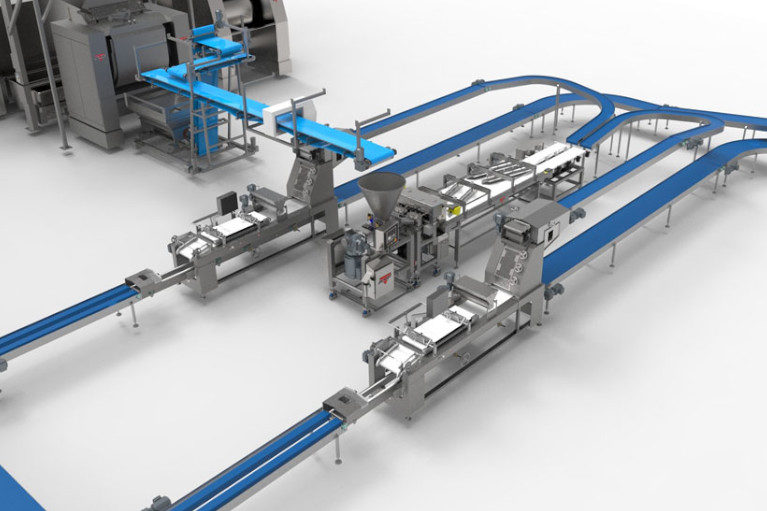

Dough handling can be a dangerous, demanding job. Risks to worker safety, coupled with the increasing pressure to provide conserve costs while delivering quality, are making automation appealing, and efficiency necessary, when selecting bakery equipment. The following dough handling solutions offer balance worker safety with other necessities.

New Processing Equipment: September 2022

Energy efficiency, automation, and ensuring a robust return-on-investment have been top-of-mind for snack food and wholesale bakery companies in the market for ovens and proofers, according to companies that make those machines, who say sales have been strong.

New Packaging Equipment: September 2022

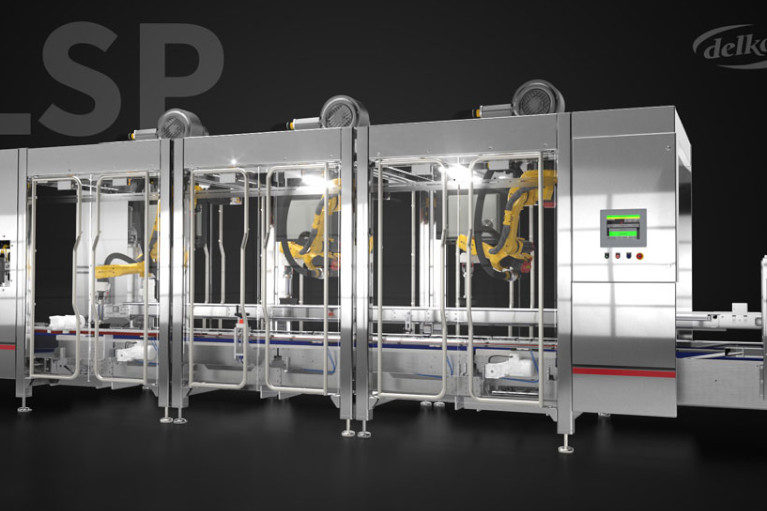

Bakery and snack plants are moving away from manual cartoning and case packing to automated equipment.

New Packaging Equipment: August 2022

When setting green/sustainability goals, consumer packaged goods companies are moving beyond a narrow focus to look holistically and collaboratively at products, packaging, and operations.

New Processing Equipment: August 2022

Snack food and wholesale bakery companies in the market for dough-handling equipment such as dividers, depositors, and rounders have been increasingly focused on machines that provide greater automation, along with the corollary efficiency and labor savings.

New Processing Equipment: May 2022

Snack food and wholesale bakery companies in the market for machines that help prepare, store, transport, and otherwise handle ingredients are most focused on qualities like automation, ease of maintenance, and the ability to deliver higher performance in throughput and accuracy.

New Packaging Equipment: May 2022

Innovation is prevalent in the area of closing and bagging equipment as well as twist ties, clips, zippers and package resealing. Thanks to product introductions and equipment upgrades, these systems run faster and are easier to use.

New Processing Equipment: March 2022

Companies that make seasoning and coating systems for snack and bakery applications, which mostly focus on salty snacks like chips, cheese puffs, pretzels, and popcorn, report a number of trends in requests regarding features and benefits from customers of such machines during the COVID-19 pandemic of the past couple years.

New Packaging Equipment: March 2022

New developments in the creation of food labels is providing bakery and snack producers with flexibility to run a wide range of different product sizes and types. Advances have been made in the following areas: printers, software, inks, and marking/coding technology.

New Processing Equipment: February 2022

Mixers serve essential functions for snack and bakery companies creating their own dough. We ask a lot of this category of heavy-duty equipment, including reliability and efficiency, to maintain established product quality-control standards.

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest snack and bakery industry trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing