Customers of cutting, slicing and portioning equipment for snack and bakery products consider a wide range of parameters: They’re hoping to find machinery that offers greater use of robots and automation, better sanitation, higher safety standards, faster speeds, wider and easier-to-clean blades, and reliable and flexible systems that can handle different sizes and shapes.

Industry feedback

Automation, sanitation and safety top the list of requests from customers of FoodTools, South Haven, MI, according to Doug Petrovich, vice president. “With the tight labor market and rising wages, we have seen a push to automate with in-line type equipment to reduce labor costs. Food safety has driven the new sanitation standards. It has come to a point where our customers want to know where stainless steel and UHMW plastic is made and what materials are in these products.” Some even ask for certifications on raw materials used. “Equipment safety is very important as workers are working in and around dangerous equipment,” he says. “It has to be guarded properly with electrical safety at the highest possible level.”

Customers of Fritsch, Markt Einersheim, Germany, want machines that can cut new shapes, forms or decorations; handle very small dimensions in an accurate and stable fashion; and slice through very thick dough sheets, says Stefan Praller, senior strategic marketing specialist. When it comes to portioning equipment, they want reliable, flexible systems that don’t need separating agents. Others, mainly in Asia, want machines that can process sticky doughs and those with high sugar or fat content that can be used in long shelf-life croissants, he says.

Telsonic, Bronschhofen, Switzerland, has seen customer demand for greater use of robots with wider cutting blades as the market expands, driven by more-exacting customer desires for cut quality, portioning control, and packaging fit accuracy and speeds, reports Martin Frost, UK sales manager. Machine processes support quicker, more-precise portioning with minimal crushing, smearing or sticking to blades.

Mike Jacko, vice president of applications & new product innovation, Urschel Laboratories, Chesterton, IN, says customers are always in search of efficient cleaning of blades, particularly when making products like bagels that have onions or poppyseeds on them that otherwise would gum up the works. And he’s seen more bread-based snacks in the marketplace. “We’re seeing more customers asking for tests when it comes to cutting bread slices, for making chip snacks.”

Customers of Moline Machinery, Duluth, MN, are asking for the capability to cut smaller products on rotary cutters, which can present challenges, says David Moline, vice president, sales and marketing. “We’re working with non-stick coatings that are still food-safe. We’ve got hot air injection and incorporate that into rotary cutting, which helps with smaller or sticky doughs.” Customers also want higher-speed cutting to bring about maximum throughput, and directly integrated cutting and portioning with an automatic panning operation, he says.

New and improved

Moline Machinery has been developing rotary dough cutters for a variety of materials, as well as stamping machines with ultrasonic guillotines that can handle smaller, thicker products like doughnuts and cinnamon rolls for which rotary cutters would not be practical. “Stamping allows you to mechanically inject from a continuous dough sheet,” Moline says. “We can cut after a product has been filled and not risk buildup on the cutter. They’re extremely flexible. They can cut almost any shape.” And Moline’s machines can reach 150 cuts per minute, he adds.

Urschel, which makes equipment for products like croutons, stuffing mixes, bagel chips and Melba toast, has upgraded its Tran Slicer line to include the E Tran Slicer, which provides improved sanitary design and greater capacity, Jacko says. And the Affinity Integra Dicer, a smaller version of the original Affinity, helps slice stickier breads that would otherwise need more drying time. “If you can get the drying time down from 48 to 36 hours, that’s a huge benefit,” he says.

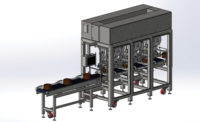

FoodTools offers upgraded benefits on three cutters and a slicer. The ACS-300RF three-station mechanical in-line cutting system is designed to cut frozen products with divider inserts, offering auto load, three servo-driven cutting stations for faster production and a roll feed divider insert system. The ACC-200FS, a two-station ultrasonic in-line cutting system designed for square, rectangular or round products, features servo-driven blade actuators, rotation and conveyor, and it can be equipped with auto load, clamps, guides, edge trim removal, individual blade cleaners and automated exit conveyors.

The FoodTools ACCUJET-10 is a high-pressure water cutter designed to cut frozen products into a multitude of sizes and shapes not possible on blade cutters, with a maximum pressure of 45,000 psig, servo-driven nozzle and product holder, large HMI and vacuum waste system.

The FoodTools RPS-100S, a single-station robotic ultrasonic slicer, is designed to cut square, rectangular, triangular and round products with an ultrasonic blade, blade cleaner, large HMI, integrated controls, and a Fanuc 7-kg six-axis robot.

A new Fritsch croissant cutting and turning system has been optimized to reach 150 cycles per minute. Fritsch has also been actively exploring the possibilities of digitalization on its slicing, cutting and portioning equipment, aiming for thoughtful, flexible technical architecture that provides smooth communication between the customer, machine and company customer service.

Fritsch Smart Services includes condition monitoring, which allows early detection of pending problems with important components like motors, frequency converters and sensors; the data cockpit, which enables real-time calculation and visualization of efficiency indicators and the possibility of custom reports to control and optimize production; and remote maintenance support, through which the company helps customers with routine maintenance and troubleshooting with an assist from data glasses that enable easy communication between customers and Fritsch maintenance technicians.

Telsonic has been focused on food cutting using ultrasonic technology, especially applications in which the technology is used in conjunction with robots. The company has developed special sonotrodes, both 500 mm wide and most recently up to 760 mm, designed for 30-inch by 18-inch tray bake applications, which can be either robot- or guillotine-machine cut as required by the volume and throughput speeds.

A growing number of food industry system integrators are using these robot-friendly modules to produce highly flexible cutting and portioning systems, for orders like tray baked products, cakes and products presented on conveyor systems, Telsonic says.