The Bottom Line:

- Automation has been advancing rapidly

- The tech can help alleviate labor challenges

- Robots save humans from dull, dirty, and dangerous tasks

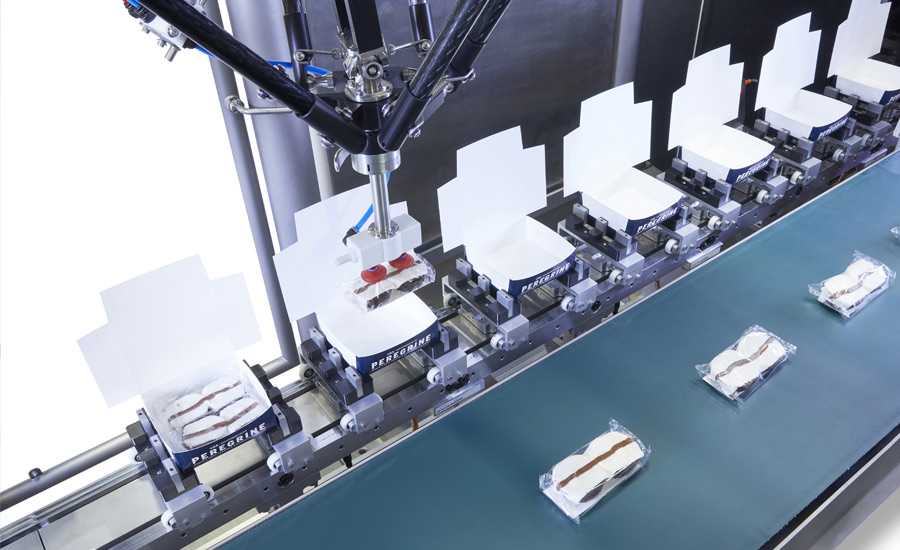

Robotics and automation are changing the snack and bakery production landscape by providing a more consistent product, improving workplace safety, and freeing up employees for other tasks. The technology allows bakeries to run production lines at faster speeds and with more accuracy than ever before while taking up less space.

In the last few years, robots have become smaller, more affordable, and more widely available. Their capabilities have expanded through improvements to machine vision, end-of-arm tooling technology, artificial intelligence, durability, and safety. Robots also have become easier to program and operate, reducing the level of technical skill needed for deployment. As these capabilities progress, robots are expanding into new applications and new industries, according to Jorge Izquierdo, vice president, market development for PMMI, Herndon, VA.

“To some extent, technology has advanced at such a rapid pace that the greatest challenge for food producers is understanding how to translate these technological breakthroughs into practical applications,” Izquierdo says. “A good example of this in snack and bakery production is the combination of vision and end-of-arm tooling that is capable of handling delicate products in random orientation with variable size and shapes at high speeds with high levels of accuracy without damaging the product.”

Larger cobots (collaborative robots) often are seen as the solution to the demand for flexibility on the production line. “Although cobots were once considered too small and slow for effective operation in many scenarios, new larger and faster models, particularly mobile ones with enhanced machine vision built in for safety, are gaining in popularity,” says Izquierdo.

Automation delivers

The bakery and snack industry is going through rapid changes: from increases in labor costs to stricter hygienic regulations, to lack of predictability caused by disruptions of supply chains and labor issues. The industry must adapt in order to continue providing food to a growing consumer market. “Robotic automation enables these plants to answer those challenges,” says Mathias Konne, food market leader North America, Stäubli Robotics, Duncan, SC. “Robots are reliable, flexible, compact, fast, and durable investments that can easily integrate with existing processing lines, causing minimal layout changes while removing production bottlenecks. In addition, hygienic robots capable of withstanding washdown processes enable these plants to automate a variety of applications.”

Integrating robotics into bakery operations enables picking, placing, sorting, and packaging product at faster and more consistent rates, which is difficult to achieve in an era of labor uncertainty. Robotics can operate at higher speeds because they aren’t limited by repeated physical activity. “Unlike the human hand, or traditional vacuum systems used to move baked goods, robotics with end-of-arm tooling can gently form around the product to lift and place it without the need for custom tooling or programming—and do so accurately without damaging product,” says Harley Green, director of business development at Soft Robotics, Bedford, MA.

End-of-arm tooling advances allow industrial robots to run at faster production speeds while still offering deployment flexibility and the necessary sanitary ratings. Advances in gripping technology apply to all sizes of articulated robots that are frequently used in small lines for pick-and-place or inspection applications. “Some grippers offer the ability to conform to irregular objects, providing additional dexterity and compliance that offer reliable pick without damaging the most delicate or fragile objects,” says Chris Caldwell, product manager, Yaskawa Motoman, Dayton, OH.

When it comes to bakery production, products must be aesthetically pleasing to potential customers. Because robots are repeatable and can handle items delicately, bakers can be confident that the appearance of their products is spot on every time, according to Chris Lorente, executive director of global accounts, Food and Consumer Packaged Goods, FANUC America Corp., Rochester Hills, MI. “The design of snack and bakery products requires creativity, and automation has raised the bar on creative possibilities. In addition, robots help reduce waste which in turn leads to less downtime, higher throughput, and a better bottom line.”

More bakery and snack producers are adapting robotics as part of their automation plans to replace workers or fill the gap left by the labor crisis (retirement and dwindling interest), says Jamie Bobyk, marketing manager, Apex Motion Control, Surrey, B.C. “In fact, many companies are building their production floors around automation, specifically robotics and collaborative robots. The previous fence sitters are now embracing this new technology.”

Big data

How do data analytics, artificial intelligence, and lean manufacturing factor into this equation?

“The more data you have at your fingertips, the better it helps to inform decision-making and add human-like elements to robotics and automation,” says Green. “Artificial intelligence can take the data that is fed to it and add more efficiency and capabilities. This helps manufacturers produce better products and meet consumer demands.”

Automation, especially robotics and vision, often brings some level of analytic capability with it, according to Craig Souser, president, and CEO, JLS Automation, York, PA. “For example, we use vision sensing on all of our systems, which allows us to report on the number and type of rejects. Artificial intelligence allows automatic changes to be made to a process based on machine learning algorithms, which adjust process parameters based on ongoing examination of the results. With respect to lean, automation will often force the issue when it is properly implemented, eliminating wasted handling of products and packages.”

Jerry Buckley, south central sales manager, BluePrint Automation, Chesterfield, VA, says that robotic vision systems can accurately review product size, shape, imperfections, and color. They can accurately reject out-of-spec items by not picking and placing them into their targeted destination (such as a wrapper infeed chain, tray/carton, or shipping case). It is difficult to accomplish this at high speeds without robotic vision systems.

Artificial intelligence and machine learning software packages are finding more applications. One interesting application for artificial intelligence for bakery and snack producers over the next few years is quality inspection, according to Caldwell. “In the food industry, where labor shortages are becoming more serious while stable quality is required, automating the quality inspection process is one path that can ensure that food is safe to consume.

“Since many food goods are produced in different formats, inspection has traditionally been done manually, making it difficult to quantify the criteria for good or bad products,” Caldwell continues. “Via deep-learning artificial intelligence, robotic inspection systems can determine no-good patterns for food products with the same level of accuracy as humans.”

When looking at ROI, food producers have traditionally focused on low variety and high volume. But with the flexibility that automation offers today, many producers can adapt to market demands and increase product variety without incurring extra costs, according to Lorente. “Artificial intelligence also offers advantages such as the ability to ‘see’ non-conforming items in production. This is advantageous for bakery and snack producers, especially when product is moving at high rates of speed and different colors are involved.”

Workforce development

How can automation help with workforce development strategies? Automation is a great alternative because plant managers can deploy robots to take on dull, dirty, and dangerous tasks and use skilled employees to do the work that only people can do. “This minimizes the need for manual labor and reduces worker compensation claims,” Lorente notes. “More importantly, it offers the workforce a better environment, increased opportunities for training, higher wages, and more retention.”

Palletizing automation has replaced many dangerous and physically demanding jobs in food production plants and warehouses. These machines can lift and move heavy products, place them carefully on a pallet, and secure them for transport, according to Ryan Weaver, commercial vice president for Robotiq, Lévis, Québec, a provider of palletizing solutions. “They also offer several benefits for workforce development by reducing the number of workplace injuries, improving worker productivity, and improving working conditions.”

What technological advances do manufacturers see in the near future? Green sees more advances in perception technology to better see, understand, and adapt to human-centric processes, which is an upgrade over the rigid solutions of the past. “Robots will continue to get faster, be able to handle higher payloads, and become even more accurate. Artificial intelligence will continue to drive better automatic decision-making to handle the unpredictable events that may occur.”

Souser says that 3D vision will be used more and more in robotics, allowing systems to make height measurements on products. “For example, new systems can determine if the top is missing on a food item even if the color of the top is similar or the same as the layer below it. The integration of inspection and vision guidance is something that we are very excited about.”