The latest innovations in fleet management offer a new world of interconnectivity that accelerates and streamlines the rapid delivery of goods to market. This is good news for snack producers and bakeries that deal with a complex distribution system on a daily basis.

Trends in the snack and bakery market mirror trends across the overall food supply chain—more-frequent, smaller deliveries made within tighter time windows, according to Will Salter, CEO, Paragon Software Systems, Dallas. “Another trend we see is the move toward fresh, not frozen, food. So there’s going to be more demand for smaller, refrigerated or multi-temperature trucks making more-frequent deliveries in order to keep items in stock while ensuring they are fresh. That, in turn, means increased complexity in routing.”

This growing demand for fresh products puts a strain on the cold chain, says Jesse Juett, senior business development associate, Zipline Logistics, Columbus, OH. “Organic and gluten-free products sometimes fall into this category, as well. Prices for temperature-controlled transport are rising while available capacity shrinks.”

Instead of making one delivery each day, it seems there are now two or three per day to the same location, according to Brian Tabel, executive director of marketing, Isuzu Commercial Truck of America Inc., Anaheim, CA. “This requires more trucks and drivers, but also smaller trucks to control costs.”

Data-driven

Online shopping and home delivery are prime examples of consumers’ changing preferences. Consumers now expect a large selection and fast delivery, which is challenging traditional supply chain systems. Innovative use of data can help fleet managers overcome this hurdle.

Predictive analytics is a big trend as more real-time, point of sale (POS) information is made available, according to Ray Zujus, strategic customer success manager for food and beverage, Verizon Connect, Aliso Viejo, CA. “Dramatic improvements in productivity, labor and asset utilization are possible by tightening up routing and scheduling activities using real-time plan vs. actual reporting, navigation with traffic and estimated time of arrival (ETA) feeds to help get product off the vehicles and onto shelves or into freezers.”

Inbound transportation management often is overlooked. However, snack producers and bakeries can take control of inbound operations by collaborating with their suppliers and carriers through portals, says Dan Clark, president, Kuebix, Maynard, MA. “Kuebix’s SupplierMAX program helps companies better manage their inbound by establishing procedures to improve supplier behavior. With portals connecting every stakeholder, companies are alerted to unforeseen events such as traffic or weather delays and can act immediately to minimize risk.”

Software advances

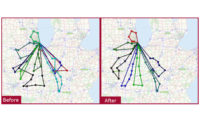

New software is available to help snack producers and bakeries cut costs and better monitor delivery of their products. Automated routing and scheduling software can cut delivery costs by 10 percent to 30 percent by making delivery routes more efficient. “It allows drivers to collect information about specific delivery sites—habitual delays, challenges with a store location, vehicle restrictions—that can then be fed into the system, allowing for improved route planning,” Salter notes.

“It also uses algorithms to streamline delivery route networks,” says Salter. “When paired with an in-cab telematics system, routing and scheduling software becomes a real-time aid to knowing exactly where each vehicle is at any given time, and that the driver is following the most-efficient route to its destination.”

Mobile enterprise management (MEM) software from Verizon Connect provides fleet managers with information on location, diagnostics and driver behavior. The broader platform encompasses truck-specific navigation, work order management, route optimization and mobile applications for ETA. “Verizon Connect Route includes tools to help with strategic planning, territory planning and appointment scheduling, in addition to handling day-to-day routing requirements,” Zujus says.

Electronic logging device (ELD) initiatives have added monitoring tools for delivery drivers, but additional options go beyond simple monitoring. Specifically, the ability to collect field-level data—such as image capture, surveys, user prompting, interactive messages, etc.—gives fleet managers more visibility to monitor the entire delivery process, according to Derek Curtis, vice president of sales, HighJump, Minneapolis. “For example, planograms have been used for years, but being able to use image capture to help fleet managers create, manage and monitor the planograms is an area has really improved in recent years.”

Thanks to ELD initiatives, fleet managers are now able to see idle time, hard acceleration and deceleration, and other maintenance-related data that provide insight into driver behavior, Curtis adds. This insight allows them to assess and adjust situations to reduce costs, and ensure that product distribution is being handled efficiently.

ELDs also promote compliance with hours of service regulations. This helps third-party logistics providers such as Zipline Logistics that have strict qualification processes for carriers, according to Juett. “We look at everything from equipment age to insurance levels and weight previous performance. By having the best carriers in our network, we can properly manage drivers and provide the best service.”

On the road

New types of vehicles are improving delivery operations, as well, according to Imran Jalal, brand and communications manager, Ford North American Fleet, Lease and Remarketing Operations, Detroit. “While stepvans and cutaways remain popular, bakery/snack producers are adding medium- and high-roof cargo vans like the Ford Transit to their fleet mix. These vans offer many of the benefits of stepvans, such as cargo capacity and ease of entry/exit, but with additional fuel efficiency. The Transit is smaller and more nimble, and has more safety features than many stepvans, along with a lower cost of ownership.” Jalal says many upfitters are equipping Transit vans with rack or storage systems. Most drivers can stand up in a medium-roof or high-roof Transit, so a van upfitted with a center aisle and storage on either side offers ergonomic benefits.

For bakeries making multiple runs to the same locations every day, particularly in a tight delivery radius, Tabel suggests the Isuzu N-Series. “For these applications, it makes sense to use an Isuzu N-Series gas truck that drives smaller, condensed routes. The Low Cab Forward (LCF) design helps the driver fulfill deliveries in smaller, more-condensed areas.”

Given the volatility of gas prices, many fleet managers are investigating or already using alternative fuels, such as compressed natural gas (CNG). “Vehicles running on propane or CNG have been added to many bakery/snack fleets, and adoption rates of these vehicles will continue to increase. We also believe electric vehicles are a perfect fit for this industry,” Jalal notes.

Todd Mouw, president, ROUSH CleanTech, Livonia, MI, sees a lot more interest in propane autogas due to that alternate fuel’s ability to reduce the cost per mile of fleet operations. “It makes business sense to leverage a domestic and value-priced fuel source such as propane autogas—which has ample supply and a clean emissions profile. We have 18,000 vehicles on the road in the U.S. and Canada. More than 1,100 public and private fleets operate our propane autogas vehicles.”

ROUSH CleanTech will achieve an ultra-low NOx (nitrogen oxide) certification of 0.02 per brake horsepower per hour later this year, Mouw says. “The purpose of this work is to help our fleet partners not only reduce their operating costs through lower fuel cost and maintenance, but also to tap into a growing pot of funding dollars available to reduce NOx.”

Looking ahead

Looking ahead to near-future advances in fleet management, Salter sees increasing demand for sophisticated electronic proof of delivery technology that will allow delivery drivers to capture and confirm more-detailed information, such as photographs that show exact location of deliveries, and allow customers to proactively manage their delivery schedules.

Also, the ability to provide predictive ordering algorithms will improve substantially, says Curtis. “Whether that is through artificial intelligence or machine learning, this is an area where the features will become far more accurate, and far more comprehensive, where solutions will start to provide ‘what if’ scenario/outcome assessments in the field.”