Company: PDC International

Website: https://pdc-corp.com/

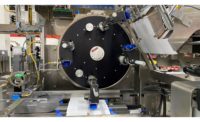

Equipment Snapshot: PDC has announced the introduction of the StackAlign Stacking & Sleeving Multipacker system. The proprietary system allows a number of individual units to be grouped, or multipacked, by stacking and shrink-sleeving them.

The StackAlign system takes individual products from an infeed conveyor, counts and stacks them, placing them onto fixed pedestals on a servo-controlled indexing conveyor. The product stacks are then centered and aligned prior to sleeve application. A dual zone hot air tunnel provides a smooth tightly fitting finish.

The system is ideal for consumer or industrial products that stack flat on top of one another. Capable of running 200 parts per minute, stacks can be made from 2 to 10 products depending on package height. The shrink sleeve can underlap and overlap the stack of products, grouping them securely for either distribution or shipping directly to the store shelves.

The PDC StackAligner uses servo-controlled rollers to meter individual parts onto an elevator while counting and stacking. Two servo-controlled elevators work successively to create stacks to maximize throughput. Prior to arrival at the elevator, individual parts are inspected by sensors to identify non-conforming units. Those that pass inspection continue on, while failed units are purged from the system.

The elevator system requires no mechanical change parts to switch between pack sizes, these changes are made electronically via stored recipes on the HMI.

The sleeve is applied by one of PDC’s mandrel style R-Series sleeve applicators. The sleeve is tamped down to confirm the film is correctly located on the stack. Sensors confirm the sleeve is in the proper position before entering the dual zone shrink tunnel.

Transition from the indexing conveyor to the discharge conveyor is achieved by a pair of hugger belts. Final orientation of the stacks can be adjusted to meet pack out needs.