The Bottom Line:

- Innovation is key

- Equipment for gluten-free snacks

- Better-for-you snacking with alternative flours

Novel ingredients and formulations—including some aimed to be “better-for-you” and others intended to be “fun”—are high on the list of features and benefits snack and bakery companies would like to see in extrusion equipment, along with ease of cleaning and maintenance, efficiency, and (naturally) the ability to produce a high-quality product.

Customers of Clextral USA, Tampa, FL, are asking for innovations to help process and extrude new snack profiles and novel ingredients, says John Barber, sales manager, U.S., and Canada.

“Getting the precise amount of expansion and the desired textures can be challenging with some grains and vegetables, depending on their starch, fiber, and oil content,” he says. “Product shapes, features, and aesthetics can be challenging with these new ingredient blends. When we are processing higher levels of protein, fiber, and/or fat, we have to test and fine-tune the process parameters to get the right snack aspect and texture. We are also being asked to meet specific diet or nutrient claims.”

Processors also are looking to keep customers engaged with their brands, Barber notes. “This goes far beyond just delivering a quality product,” he says. “It can be making the snack more fun with a new shape, or more enticing with a new flavor combination. Some companies are asking for customer feedback through their social media channels, and then working to create and design these new snacks. It’s important to stand out, both on the shelf and in people’s minds.”

Nico Roesler, North American pretzel and snack equipment sales manager, Reading Bakery Systems, Robesonia, PA, says customers are focused most on efficiency and “bang for the buck, getting the most product out of the machine possible, and making sure that product is consistent and high-quality.”

Snack and bakery companies also are increasingly interested in the ability to create gluten-free varieties of traditional snacks like pretzels. These types of doughs require pre-feed rolls to ensure even and accurate distribution of the dough in the extruder because the dough does not have the strength or elasticity that gluten otherwise brings to the process, Roesler says.

“A lot of conversations with customers center around better-for-you snacking, adding protein content to traditional snacks, and finding alternate flours to provide better-for-you attributes,” he says. “We’re seeing other types of flavors, like legume flours, incorporated in the pretzel doughs—maybe not going fully gluten-free but offering some health benefits.”

Product trends like bite-sized snacks and health claims like organic are top-of-mind for customers of Egan Food Technologies, Grand Rapids, MI, says John Micelli, who handles sales and market development. “In the granola world, plant-based is big,” he says. “In the bar world, I am seeing a lot more nut and seed bars coming online.”

Sanitation and ease of cleaning are other priorities for customers, Micelli says, adding that Egan’s machines are all stainless steel and can be washed down in place. “They want it easy to change out one product to the other, with simple maintenance to remove components so they can be cleaned and washed,” he says. “Sanitation is huge, no matter what piece of equipment. … People like tool-less; infrequently as possible do they want [employees] to reach in and get a ratchet or screwdrivers. They want people to do it with their hands.”

Company

Clextral USA

Featured Product

Flexible line solutions, extrusion kits

Clextral has rolled out two innovations in recent months: flexible line solutions to produce a greater variety of snacks on one line, ranging from savory, to sweet, to better-for-you; and new plug-and-play extrusion kits that give snack processors a variety of options for shapes and ingredients like smiley faces, hearts, ovals, and pea pods, Barber says.

The flex lines provide the ability to process a wide variety of products, from savory snacks to sweet cereals, all in one line. “They are smart extrusion lines capable of directing a variety of extrudates to an array of downstream equipment,” he says. “Flex lines allow our customers to keep their processing line busy to maximize its utilization and profitability.”

The extrusion kits are designed for snacks that are directly expanded or puffed, and they can be either retrofitted to existing equipment or purchased alongside new equipment, Barber says. “The kits enable the production of new product styles, [such as] extruded pillows with a twisted shape, crispy shell, and soft filling,” he says. “They include quick-change dies, guides, and downstream equipment that allow maximum flexibility and efficiency, while producing a top-quality product.”

Company

Reading Bakery Systems

Featured Product

WCX Wirecut, Dynabite

The most significant recent innovation from Reading Bakery, which was on display at the IBIE show in September, is the WCX Wirecut machine, an improvement on the company’s previous model that adds significant flexibility, Roesler says.

“Bakeries can include up to 14 servo motors to control different cutting paths for extruded products, batters for cookies and bars,” he says. “The machine incorporates options to make multi-doughed cookies and bars, filled bars, and multi-colored cookies. For encapsulated cookies, the Iris cutting mechanism pinches the dough around the filling. So, for example, you can have a peanut-butter-filled cookie.”

The WCX Wirecut also adds versatility to multi-dough cookies, enabling a chocolate and vanilla swirl pattern, for example, Roesler says. Lastly, the machine’s ultrasonic cutting mechanism at the extruder nozzle allows producers to slice sticky and/or hard, brittle inclusions for cookies or bars. “The ultrasonic cutter can be placed on the belt after the extruder to cut things like bars or other pieces,” he says. “You can incorporate ultrasonic cutting at multiple stages.”

In addition, Reading Bakery has modified its standard low-pressure extruder to allow for the creation of a new take on the traditional broken pretzel product called the Dynabite that was also exhibited at IBIE, Roesler says. “We take an extruded rod … send it through the slicer, and that slices the rod into same-sized nuggets of pretzel pieces,” he says. “One benefit of that is that the exposed interior of the pretzel can absorb seasoning better. It creates uniform shape sizes rather than randomization, and you get open interior space that’s more porous for absorption.”

Company

Egan Food Technologies

Featured Product

SlabForm DUO

Egan Food Technologies has made an assortment of automation upgrades to the SlabForm DUO, designed for smaller bakeries and snack bar manufacturers, with a two-lane system that slits wide slabs of bar material at the outset rather than later in the process, Micelli says. “Then it’s a matter of guillotine-cutting it into the length you want, and it’s done,” he says. In addition, it’s a compact machine, about 10 feet long, and costs under $100,000.

Egan has added a module to the SlabForm DUO to create bite-sized products, about one-inch square, which Micelli says have been a challenge for smaller manufacturers to achieve from an economic standpoint. ”What it actually does is add a slitting option, to slit these into little cubes,” he says. “Even on the small machine, it allows you to produce 500 to 600 bites per month.”

Other new add-ons include a pre-feeder, slitter/spreader, retract conveyor, and cooling capabilities. In addition, during the first quarter of 2023, Egan will add an option to combine an extruder onto the line, allowing it to be multi-function, Micelli notes.

Company

Reiser

Featured Product

Vemag Portioner

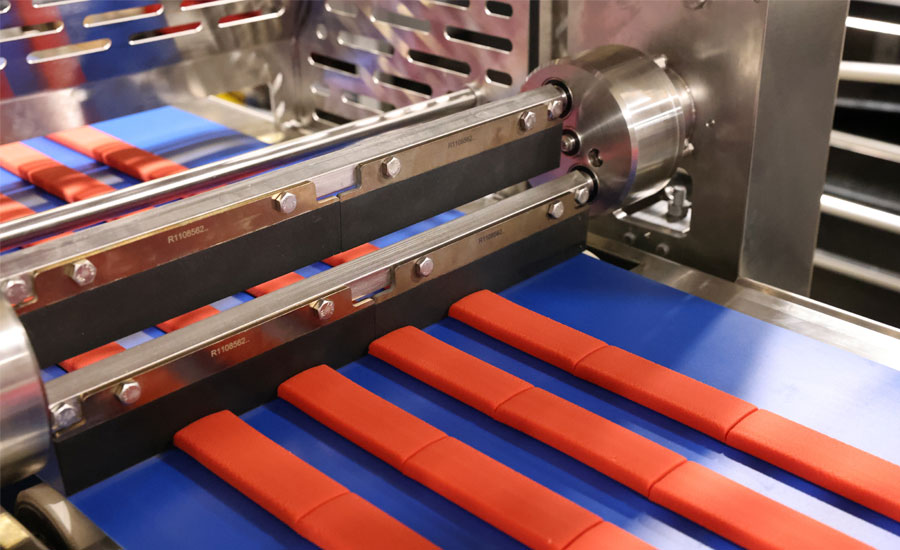

Another new product exhibited at IBIE is the Vemag Portioner from Reiser engineering, which adds a new cutting device to the Vemag multi-lane bar extruder. The scalable device can be made with varying widths of extruder and cutter, meaning that four, eight or 10 lanes and more all can be accommodated depending on production requirements. The portioner produces high volume and bars that are identical in length, with clean, even edges, the company says.

Available in a variety of models and hopper capacities, the Vemag Portioner features a positive displacement double-screw pump to provide the high accuracy, Reiser says, while gently transporting product to avoid smearing or crushing particulates that are both large and delicate.