Celebrating more than 25 years under its current ownership as “the world’s custom food maker,” Little Lady Foods, Elk Grove Village, Ill., develops, contract-manufactures and packages for private-label, foodservice and branded products for retail customers. While it may not have a name that’s widely recognized at the retail level, the “little” company has grown from $100,000 in sales in 1984 to well over $200 million today.

Jointly led by third-generation family members, Dan and John Geocaris, Little Lady Foods listens to customers with all ears and carries out sophisticated product execution, equipped with a fully staffed research and development team, technical team, sales and marketing team and operations/production department, as well as process and culinary trends experts.

Versatile production/packaging stations

The company can scale up recipes on a national level for some of the biggest, most prominent food companies in North America and beyond, and also provides marketing, merchandising, logistics, supply chain solutions and more to make everything as easy as possible for its major-league customers. One of the Elk Grove Village-based production facilities has a culinary center for product development, recipe testing, quality control and customer collaboration. The culinary research and development team and executive chefs design new food creations to go with every customer’s concept, fine-tuning recipes and helping to develop new ones.

Little Lady Foods strives to accommodate all customer requests, says Chris Celeslie, vice president of operations. “We can add fire-roasted, mixed grilled vegetables by hand, for example, or we can slide in automatic vegetable topping machines.” Packaging, which is also performed in-line, is based on the same principle. “Most of our equipment can be moved in and out because it’s on wheels. We can shrink wrap the pizzas, use a flow-wrap pillow-pack or we can use modified atmosphere options and carton or not carton. That’s really a bonus for customers—problem-solving their issues.”

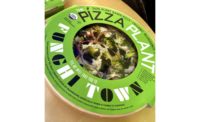

Snack Food & Wholesale Bakery visited what the company calls its West facility in Elk Grove Village, one of two production locations there (the other is, of course, aptly named East). The two plants primarily produce frozen pizzas of every kind. The company’s third facility in Gurnee, Ill., produces frozen hand-held sandwiches, foldovers, paninis and other products.

There are two pizza production lines at the West plant and three at the East plant. The Gurnee facility is outfitted with two lines for sandwiches and hand-held items and two lines for frozen pizzas. About a year ago, the company consolidated most employees into a larger, 20,000-sq.-ft. corporate complex across the street from the two Elk Grove Village production facilities, freeing up needed space to expand plant operations.

All three plants operate two 10-hour shifts a day using a swing crew, explains Celeslie. “We run four 10-hour days, with three crews per line. The plants operate six days a week, but we alternate crews so that each crew works four days a week.”

Process separation

The West facility was upgraded last year, Celeslie points out. “The West plant has two production lines that run all kinds of pizza products,” he says. “We also took on a process separation project for the plant, whereby we keep baking of the crusts separate from the pizza topping area where we have pepperoni, sausage and topping application. This facilitates cleanup and sanitation and enhances our quality standards.”

All three plants also feature metal detection in production areas and follow statistical process control and Hazard Analysis Critical Control Points (HACCP) guidelines. “We try to stay very far ahead of food safety regulation,” says Celeslie.

At the time of Snack Food & Wholesale Bakery’s visit, the line was running a nationally branded retail pepperoni/veggie pizza at 150-200 a minute. Among other stations, the line is equipped with a hot press for 12-in. pizza crusts and a multidimensional stone-fired, brick oven. “This gives us a crispy crust with the right color on the top and bottom. Brick oven baking of these crusts is clearly our forte,” Celeslie says.

The line also has a continuous conveyor that feeds from the bakery section to the processing and packaging sections, but is separated into two rooms, he observes. “This line is different from the others because it separates the bakery from the processing. The line still has a continuous feed, but the bakery section flows out into a processing area, which allows us some flexibility to do some things that we historically haven’t been able to do.”

Production begins in the mixing/sheeting/pressing area, where flour, water and oil are automatically piped overhead to a pair of horizontal mixers. The West plant’s outdoor flour silo holds up to 150,000 lb. Salt, sugar, spices, yeast and other ingredients are batched into the mixture from sacks. In this case, multigrain dough is being made. After the dough is mixed, it’s proofed at humidity-controlled ambient temperatures in oblong dough troughs that sit in the same area. In this case, the dough balls are timed to proof for 15-20 minutes at 70°F. Every customer’s product has a different proofing time and proofing method. The dough can also be placed on proofing racks, depending on the product and its requirements.

The batch of dough being made was about 1,000 lb. “We can produce batches up to 2,000 lb.,” Celeslie notes. “Every product is different and we customize our batch sizes according to line speeds and proof times.”

When ready, the dough is dumped into the hopper of a punching system that forms it into balls. The balls are transported to the main line, where they’re placed onto the infeed of the hydraulic hot press, which presses them into pizza rounds using heat and pressure to squeeze the dough into a round crust shape. Red LED (light-emitting diode) photoeye lights on the conveyor indicate to operators exactly where to put the dough balls. “For every pizza size and shape we produce, there’s a different LED light indicator used on the press,” Celeslie points out.

As the flat multigrain rounds of dough progress toward the oven, line operators adjust them if needed on the wire mesh conveyor. They’re also inspected for quality control purposes. An olive oil sprayer prevents the dough from sticking to the conveyor.

Brick oven-baked

Just before the flat rounds convey into the 40-ft.-long stone-fired brick oven, they pass beneath an automatic rotary docking station that docks them to prevent bubbles of air from becoming entrapped in the crust. Temperatures, time and relative humidity depend on how thick a crust is to be made, says Peter Cokinos, senior vice president of sales and marketing.

As the crusts turn a golden brown color, they move through four zones within the brick and a fifth zone that achieves a final coloring on the top. They emerge golden brown on the bottom and crispy and soft on the top. As the baked crusts exit the oven, they drop onto a separate conveyor at a 90-degree angle.

The line flows so that the pizza crust comes out of the oven, exits the room and enters the aromatic topping room, where sweet smells of tomato sauce fill the air. “The lines are very flexible and portable,” explains Celeslie. “We can move equipment in and out, from line to line, depending on what a customer needs. We can also run the same product in our different plant locations, if necessary.”

Into the topping room

The post-oven stations on the line are really where Little Lady Foods hits its sweet spot with customers, Celeslie continues. “We can add ingredients to the crust either using machinery or by hand. We have automatic and manual topping stations, so it’s the customer’s choice of what they’d like. The topping application machinery is portable. We’ve designed our lines so that we can slip a piece of equipment in and out or add a manual station.”

A rotary takeaway system at the end of the oven was added for the crusts. The system uses vacuum to gently allow the crusts to drop onto a conveyor off of the brick. Next, the crusts cool under fans and move into the next room, where line operators place the crusts into the three-lane infeed of a sauce depositor where they receive (for this application) a tomato sauce topping.

Next, the sauce-topped crusts convey three-across into a waterfall shredded cheese applicator, where they receive a blend of shredded mozzarella and provolone cheese before they head to a meat application station. For this production run, slices of pepperoni are precisely placed onto the moving pizzas. Several pepperoni sticks are placed in an infeed on the automatic slicer, which uses patented blades to slice and apply pepperoni in predetermined patterns according to requirements.

Once the meat is applied, line operators sprinkle on a mix of chopped, fire-roasted vegetables such as onions and three colors of chopped peppers and add a sprinkle of basil, oregano and other spices as well as a helping of grated Asiago cheese. Operators also adjust any of the pepperoni on the pizza at this point. “Tomorrow perhaps, we will slide out that manual vegetable topping station and put in automatic topping machines,” Celeslie points out.

Cartoning, casing, palletizing

With toppings in place, the pizzas head into a nitrogen tunnel freezer, a 40-ft.-long unit that freezes the pizzas in two minutes at sub-zero temperatures amidst a cloud of frozen condensation. Exiting the freezer, the frozen pizzas each are hand loaded onto a backing card and are sent through a shrink wrapper single-file to an L-bar sealer that wraps them in clear film. Next, they convey toward a shrink tunnel, which shrink-wraps them snuggly before they make a U-turn over to the packaging area.

As the pizzas single-file to a checkweigher station, which is a quality control checkpoint, they pass through a metal detector before they move on to the packaging area. There’s a rejection bin for the checkweigher on the side and below the conveyor. The bin is locked, Celeslie says.

“Only the QC department can open and inspect the bin if anything is rejected from the metal detector,” Celeslie says. Cartoning is next. Operators slide the pizzas through the cartoner, after a date coder prints a production code onto the cartons. The cartoned frozen pizzas are then manually case-packed by the dozen and the corrugated shipping cases are automatically taped closed. Cases are erected manually for now, but that’s something the company would like to automate, Celeslie says. Palletizing and pallet labeling is also performed manually before the pallet loads are forklifted to a stretch wrapper in the warehouse nearby. “It might be nice to have a production line run the same thing each day, but when you talk about our flexibility, it trumps all of the automation,” says Celeslie. Then the loads are moved into a 20,000-sq.-ft. storage freezer.

In this location, there is a holding room where all incoming materials are separated, he adds. “We revised this last year to improve product flow,” he adds. “That way, there’s no cross-contamination. Frozen and refrigerated goods move into the beginning of a process separation step so that none of the at-risk ingredients are allowed beyond a certain point. We’ve focused on process control at every stage. Every ingredient we use comes into this room first so that items flow from this room to cleaner rooms as they’re unpacked. Everything is separated from its pallet and shipping cases. The clean contents are brought further and further into the plant that way so that we can control environmental pathogenic issues. The outer packaging that arrives at the facility will never reach certain areas.”

The plant runs on a just-in-time (JIT) basis and product shipments are handled by common carrier. “We only bring in what we need for today,” Celeslie explains “Then we will clean everything out tomorrow, so that’s why you only see a few refrigerated goods.”

The production lines at the East plant are being retooled and upgraded, so the existing business is being absorbed by the West plant. “We hope to automate the packaging area a bit further, including case packing, loading and palletizing,” says Celeslie. “We’re satisfied with the level of automation that we have on the topping end and the bakery end.”

Environmentally speaking

The three plants recycle as many materials as possible, including plastics, corrugated and packaging film, and all of the waste is managed. “We give edible items to feed farmers and the only things going to landfills are what can’t be recycled or doesn’t have a recyclable location,” Celeslie adds. The company has converted as many packages from virgin to biodegradable materials, and the majority of customers use recycled packaging components, he says. “We also upgraded all of our lighting, utilities and meters on all inbound materials.”

The company enforces strict quality and safety standards to produce the highest quality products. The three plants also received Level 3 of the Safe Quality Food (SQF) certification. “Having so many national customers ensures that we have the best food safety standards,” Celeslie says. “Our environmental pathogen controls are top notch.”

If that’s not all, Cokinos says sweet developments in dessert pizzas may not be far behind. “As we continue to work with customers, we’ll use our unique portfolio of culinary experts to assist on developing dessert pizzas such as fruit pizzas and other new and exciting items.”