Company: Eaglestone Equipment

Website: www.eaglestone.net

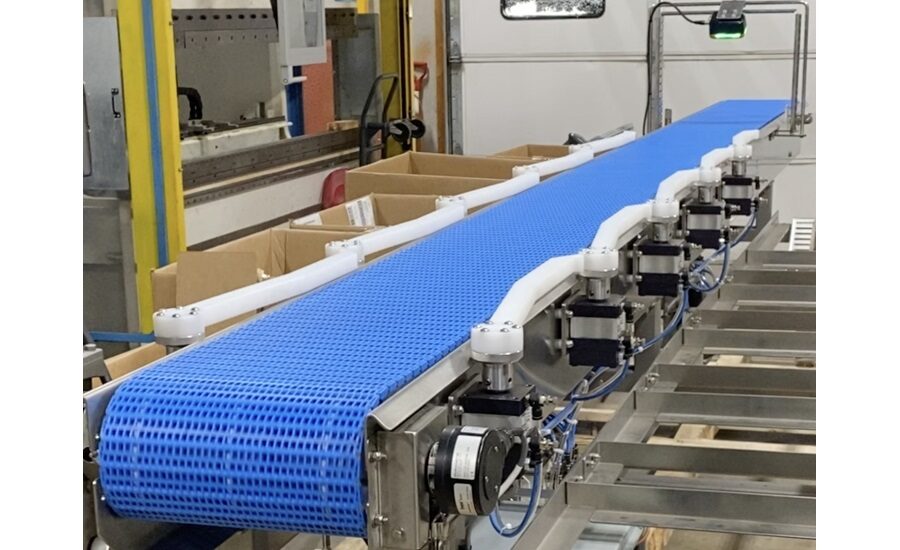

Equipment Snapshot: Eaglestone Equipment, a custom manufacturer of industrial processing equipment, recently introduced the TrackIQ Sorting Conveyor. The TrackIQ streamlines operations by automatically sorting items according to color, size, weight or bar code. Its innovative technology offers faster, more precise sorting to industries such as telecom, logistics and food processing at an affordable cost.

“We are incredibly excited to launch the TrackIQ Sorting Conveyor,” said Carmen Sammauro, president, Eaglestone Equipment. “There is not another machine on the market like TrackIQ and it offers a multitude of advantages. This sorting conveyor is extremely accurate and eliminates the need to sort products and load boxes by hand. Whether the product is smartphones, auto parts, or baked goods––we create the ideal system to meet requirements in every way. One of the greatest advantages TrackIQ offers is its unbeatable ROI. In fact, operating costs and maintenance are relatively minimal for this sorting conveyor. The TrackIQ Sorting Conveyor is also modular and designed to grow with the needs of a company. This means our customers can start small and extend the system as business requires. Whatever variables are selected for sorting parameters, our new TrackIQ Sorting Conveyor will help operations increase productivity.”

The TrackIQ Sorting Conveyor offers sorting and packaging advantages:

- Exceptional accuracy

- Faster processing

- Zero wasted labor

- Forward-thinking modular design

- Custom built in the USA

Processing operations are continually looking for ways to promote productivity while maintaining quality. With a single operator, the TrackIQ Sorting Conveyor eliminates wasted time and labor required for sorting and loading products by hand. Costly mistakes due to human error are completely avoided. Operations no longer need to outsource projects.

Sorting conveyors are a crucial piece of equipment when it comes to transporting and handling materials. The TrackIQ Sorting Conveyor offers accuracy and efficiency like no other product on the market today. The TrackIQ is the first sorting conveyor of its kind that sorts items that are not boxes. TrackIQ technology utilizes Eyesafe infrared scanners that identify items as they come down the conveyor. The items then continue past a series of adjustable-speed oscillating arms, which push them into a designated box or send them on their way. When the container is ready for packing, bright LEDs light up to alert the facility.

The many advantages of conveyor sorting systems is propelling market growth for the industry. Business Wire forecasted the conveyor sorting systems market to grow by USD 947.47 million, progressing at a CAGR of over 5 percent during the forecast period.

Eaglestone’s highly experienced engineers can design a TrackIQ Sorting Conveyor to fit unique facilities and pre-existing lines. A multitude of custom options are available including:

- Blast gate

- Diverting chute

- Full welding

- Push off

- Retracting end

- Side guides

- Stainless steel casters

- Stainless steel motor and reducer

- Other options upon request

See TrackIQ in action and find out more about how Eaglestone Equipment can save manpower with smarter sorting by visiting www.eaglestone.net.