Food safety will always be a major concern for bakers and snack manufacturers. Final rules pertaining to the Food Safety Modernization Act, signed into law in 2011, will begin rolling out this year. In addition, consumer awareness of food safety continues to grow due to more major food recalls and readily available information about this subject.

A question of sanitation

To ensure that their products are safe, bakers and snack producers are implementing new or enhanced sanitation programs, which can be more costly and time-consuming than their previous programs. So when it comes to replacing their processing equipment, including conveyors and belts, food safety, sanitation and maintenance are key considerations for these manufacturers.

“One of the biggest trends in food manufacturing today is increased attention on improving food safety,” says Peter Wood, process systems product manager, Key Technology, Walla Walla, WA. “This puts enormous pressure on processors to enhance sanitation, since the most-effective way to reduce the risk of product contamination is through prevention. Conveyors, because they are ubiquitous in food plants, are being scrutinized in their ability to contribute to, or undermine, sanitation initiatives. Of course, reducing maintenance and limiting the total cost of ownership continue to be high priorities.”

In October, the company introduced the Sanitary Belt Conveyor for transporting bulk foods, including potato chips, crackers, nuts and other snack foods. The model features a positive-drive urethane (PDU) belt that’s thermoformed to meet an application’s exact needs and doesn’t fray, delaminate or harbor bacteria. A uniform surface makes the belt easy to clean, reducing downtime and minimizing water and chemical use.

Key Technology’s PDU belt conveyors can be designed with a flat surface or a variety of shaped flights and/or flexible sidewalls to keep product in the pockets while elevating.

“If sanitation is a manufacturer’s top priority, vibratory and horizontal motion conveyors may be the better choice than belt conveyors because they eliminate product contact with moving parts and present a flat-bed surface made of easy-to-clean stainless steel,” says Wood.

Last July, the company introduced a rotary polish as the standard finish for its vibratory conveyors. The polish provides a smooth, stainless steel surface that resists bacterial attachment to maximize food safety.

In November, Dynamic Conveyor Corp., Muskegon, MI, introduced the DynaClean Vertical Z Conveyor, which features a space-saving design that allows product to convey vertically, like a bucket conveyor. But compared to bucket conveyors, which run on two chains, the Vertical Z Conveyor is easy to clean, reducing hours-long cleaning routines to minutes, notes Jill Batka, president of the company.

Batka also suggests the conveyor is virtually maintenance-free: “The conveyor is self-lubricating and requires no oil or lubrication. The belts offer a positive-drive that will run continuously, without the need to be re-tracked.” She also points out that the belts are thermoformed from polyurethane and offer a solid surface that will not fray or delaminate.

In addition, the DynaClean Vertical Z Conveyor is easy to take apart without tools and has no “nooks or crannies,” further reducing cleaning time and required resources, says Batka. It handles a variety of products, including nuts, seeds, chips, cereals, granola, dried fruits and marshmallows.

Easy sanitation and maintenance and a robust design are key features of all Kofab conveyors, says Bill Schiltz, director of sales and marketing for Kofab, Algona, IA.

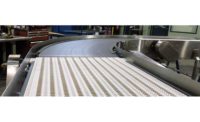

The company’s line includes the Curveyor, a powered belt turn model used primarily by manufacturers of cookies, crackers and other items that require product orientation. Available belt sizes for the Curveyor range from 14 to 84 inches wide, with turning ranges from 45 to 180 degrees. Also in the line are three positive-drive belt conveyors: the Eleveyor, which can be used to transport bulk snack from production to packaging areas; the Troughveyor, which handles cereals, powders and other bulk items; and the Doughveyor, which handles raw dough.

Manufactured in the U.S. to fit customers’ specific applications, Kofab conveyors have a continuously welded, stainless steel construction that prevents water collection; tool-less disassembly for cleaning; and solid urethane belts. “Most are cleaned with a quick-release, take-out mechanism that’s either mechanical or pneumatic,” Schiltz explains. “We also incorporate belt lifts to lift up the belt, so it can be cleaned on the bottom.” Optional clean-in-place (CIP) systems are also available.

Movement improvements

“The ability to efficiently clean both conveyor belts and conveyors is one of the most-important trends we have noticed in recent years,” says Kenneth King, commercial support manager, Ashworth Bros. Inc., Winchester, VA. “We see consumer demand for quality food products and changing government regulations as the driving force for improved conveyor and conveyor belt design.”

Ashworth’s new Omni-Flex 3 x 1 belt, with its 3-by-1-inch openings, offers customers the same Omni-Flex belt design introduced by the company in 1959, but with less overall weight. “The reduction in belt weight makes this a more-economical alternative for conveying products in pans, trays and other bulk containers in applications where Omni-Flex belts or similar style flex belts with smaller openings have been traditionally used,” says King. He suggests that the belt is ideal for applications where belt weight has typically limited the ability to increase product loading, thereby preventing increased product throughput.

Killian Lapeyre, global snack team leader, Intralox, New Orleans, says his company also is seeing “a push for more-sanitary design. Easy access and open design are becoming more prevalent. Therefore, we continue to improve and expand our sanitation products and services.”

Intralox’s ThermoDrive Synchronized Sidewalls (SSW), introduced in 2013, offer manufacturers several enhanced sanitary and reliability benefits: improved food safety, easier cleaning and improved control and containment of small or fragile food products. They also provide increased throughput and product quality benefits for incline applications.

Synchronized Sidewalls are hermetically sealed to the ThermoDrive Belt, which reduces product damage otherwise caused by static sidewalls. By reducing the gap between the sidewalls and flights to 5 mm, the belt also minimizes product fallback, thus increasing product quality.

ThermoDrive SSWs are currently used throughout the bagged snack industry, most commonly for chips, extruded products and confectionary products.

“Food safety is becoming more important by the day,” says Sara Alcalde, bakery team leader, Intralox. “Both conveyor designs and components included in the belts are being affected by this trend, and we can see how bakers are placing more emphasis in the conveyor design or the belt/components they chose for their operations.”

In the past year, Intralox has released several new belts and technologies for its baking customers, including the ProTrax belt. “We introduced our ProTrax to help track pans in the bakery through inclines, indexers and switches without the need for external or additional magnets, which often require a lot of maintenance and represent a food-safety risk,” Alcalde explains.

The ProTrax belt will replace rough surface belts and metal chains, eliminate the need for conveyor magnets and offer customers benefits in terms of reduced maintenance, no mistracking of existing belts and the elimination of some mechanical brakes. The belt also will be able to simultaneously handle different pan sizes.

“One trend that has been taking shape for a number of years is the need for easy cleanability,” says Rick Spiak, vice president of sales and marketing, Wire Belt Company of America, Londonderry, NH. “This has become more of forefront issue since bakers and snack food producers are getting into more and more cleaning cycles to remove allergens from the mix in their production facilities.”

Wire Belt provides a variety of products for the baking industry that fit the bill, including the Compact-Grid, Versa-Link and Flat-Flex. The Compact-Grid is best-suited to the snack food, biscuit and cracker side of the industry, says Spiak, while the Flat-Flex can be used in bakery applications ranging from sweet goods and other coated products to tortilla cooling conveyors, cracker-spraying operations and artisan bread cooling lines. The Versa-Link, meanwhile, can be used in pie-handling, small pan-cooling and many other baking operations.

According to Spiak, all of Wire Belt’s products offer optimal open surface area with an excellent product support grid for carrying baked and snack products through numerous different operations. The belts’ open-mesh design gives them versatility, making them suitable for operations that require solid-product support in a transport mechanism, yet still allowing excellent air flow-through for cooling and heating, and flow-through of liquids, granular solids and powders for coating operations.

Food safety and equipment sanitation and maintenance will always be important to bakers and snack manufacturers as they strive to meet new federal regulations, retain consumer trust and grow their businesses. New conveyors and belts will help make the journey forward smoother.