In 1989, when La Brea Bakery opened its doors, it introduced Los Angeles to the sublime beauty of artisan bread. Fast-forward to 2016, and La Brea Bakery has grown into the largest baker of nationally distributed artisan breads in the U.S.—breads that still retain their original artisan allure.

La Brea Bakery has also taken an industry-leading position on non-GMO breads and brought the concept of “farm-to-table” breads, made with heritage grain, to a national audience. And the bakery has forged new ground with gluten-free breads that mesh with the bakery’s artisan sensibilities.

All the while, La Brea Bakery has brought truly artisan, long-fermented bread to countless households through a masterful combination of operational efficiency and a stalwart adherence to the artisan ideals that grounded the bakery at its inception in 1989.

For these reasons and more, Snack Food & Wholesale Bakery has named La Brea Bakery as its 2016 “Bakery of the Year.”

Steady growth

La Brea Bakery began as a small storefront on La Brea Avenue in Los Angeles, offering six archetypal artisan breads: sourdough baguette, country white sourdough, whole wheat, Normandy rye, olive and rosemary olive oil. “The word quickly spread about the unbelievable breads being made, and we’ve been growing ever since,” says Kristina Dermody, president.

Necessity was the mother of inception for La Brea Bakery. Nancy Silverton, the bakery’s founder, was unable to find breads in the area that met her standards for her restaurant, Campanile. She sought truly artisan, Old World breads like those she savored during travels in Europe.

“She made the decision to teach herself to bake,” says Dermody. “After a great deal of trial-and-error, she developed her own starter from scratch. Using flour, water and wild yeasts from the skin of organic grapes, she created a living, breathing masterpiece that would ultimately become the signature ingredient in every loaf of La Brea Bakery bread. We actually have some of our starter mother sitting in a vault in Belgium.”

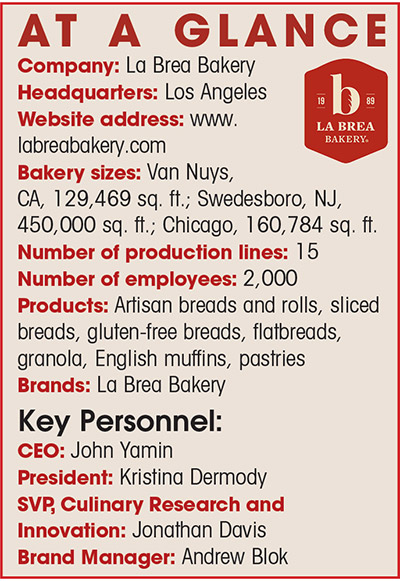

Good ideas love to grow, and in 1992, the company opened a larger bakery in central Los Angeles to serve the growing demand for breads and pastries at regional stores and restaurants—a bakery that still operates, serving area direct-store delivery (DSD). Then, in 1998, the Van Nuys, CA bakery opened to support national expansion. In 2001—the same year Zurich-based ARYZTA acquired the business—La Brea Bakery opened a facility in Swedesboro, NJ in order to keep up with demand. Most recently, in 2014, La Brea Bakery acquired a flatbread bakery in Chicago.

La Brea Bakery serves a national customer base across all levels of retail and foodservice. The in-store bakery is a primary retail outlet for La Brea Bakery’s take-and-bake breads, and the company works to set up retailers for success. “There’s a full training program that goes into every new launch,” says Andrew Blok, brand manager, working with new retail partners to establish the market and educating them on the nuances and styles of the breads.

“We visit with the leadership at retailers and do cuttings of the breads, tasting them and talking about the process,” says Jonathan Davis, senior vice president, culinary research and innovation.

For La Brea Bakery’s foodservice customers, a certain amount of collaborative customization is welcome.

La Brea Bakery also still operates a café on La Brea Avenue in Los Angeles—just down the block from the original location—as well as another location in Disneyland. Franchised locations operate out of several major U.S. airports.

“Today, our breads are sold in all 50 states and 22 countries,” says Dermody. “However, we’ve never forgotten where we came from. We continue to instill the same strict quality standards and artisanal baking methods we’ve had since inception.”

Artisan has always been at the heart of every La Brea Bakery bread. “It’s dedication to the quality,” says John Yamin, CEO.

“It’s also the integrity of the breads,” adds Dermody. “It goes back to the process, and we’re not going to compromise on the processes that were set 27 years ago. It also goes back to the values and integrity on the line, the people who are working in the bakery each and every day.”

Despite this considerable growth, much remains the same at La Brea Bakery. “Our core has remained fairly consistent over the years, and our top loaves, baguettes and rounds have unbelievable loyalty and appreciation,” says Dermody. “Our Italian round is a favorite with our consumers.”

Growth at La Brea Bakery has also recently come through gluten-free. “I worked with various partners through grueling R&D and supply-chain work to come up with something that is truly unique,” says Davis, who has a family member diagnosed with celiac disease. “We had to find unique ingredients that weren’t readily available. We had to find production processes that weren’t available. We had to go through every part of the makeup of the bread and create something new. We created something that, quite frankly, you can eat right out of the bag—soft, pliable, tastes good, can be used in place of regular sandwich bread.”

The La Brea Bakery process

La Brea Bakery has stayed focused on its bread while growing into its current state of operational efficiency. “We focused on the bread as opposed to how to make the bread,” says Davis. “We designed all the machinery around the bread. Essentially, we stuck with the same types of mixtures that we’ve always been accustomed to, just in larger quantities. We use the same types of ovens as on the small scale—again, just on a much-larger scale. We stick with what we know.” The precision of automation keeps products within tight specifications, while gentle handling of the dough preserves artisan quality.

Although some automation is present in ingredient-handling systems, batching is still done manually. “The start of the process is the key, that’s where you need your knowledge,” says Brendan J. Maguire, bakery director. “That’s where you need your consistency with the advantage of skilled operators. I shied away from harnessing them into something that was rigid and automated. Sometimes things happen—sometimes doughs are a little different.”

The supply-chain management system uses predictive analysis based on sales patterns. “We get a prediction every week that shows us, for four to six weeks ahead, what we expect to be making,” says Maguire. “It helps us be efficient, whether it’s packaging or an ingredient.”

La Brea Bakery recently completed a new, state-of-the-art, thermal-oil, artisan bread line in its Van Nuys facility, built with top sanitary design and operational efficiency features—and there’s plenty of room for an additional line in that pristine space when the time is right. Davis notes that La Brea Bakery prefers thermal-oil ovens for their precise control of heat, moisture and artisan crust development.

“The new line is geared toward sandwich-type breads, such as tortas,” says Maguire. It’s highly automated, but every La Brea Bakery line features some element of baker contact. For instance, the line features an automated bun/roll slicer for foodservice customers. But for breads that require scoring, line operators still manually complete that task. “I like to have automation in key places to help people, but leaving flexibility for the skills of a craftsman,” he says.

“We have 15 production lines in our artisan bakeries,” says Dermody. All of the lines are multipurpose, with capability for running several different types of artisan bread or rolls. “Although we have automated over some aspects over the years, the lines are designed to mimic the same process we have used for over 27 years, and every loaf is still touched by hand.”

This hands-on approach extends to maintenance, as well. At Van Nuys, Maguire notes that they have the ability on-site to manufacture necessary parts about 85 percent of the time. Full-time software technicians at the bakery handle programming tasks for the lines.

While moves toward increased automation through the years have considerably streamlined production, the bakery doesn’t necessarily keep driving for faster throughput. “We don’t tend to push it that much,” says Davis. “When you start to push it or strain the system, you start to see quality degradation. We’ve actually slowed down some of the production to make sure we maintain our quality.”

The mantra is, “Make the best loaf of bread you can,” says Blok.

Maguire estimates that the Van Nuys bakery runs about 1.5 million lbs. of dough a week.

The Swedesboro bakery recently improved its end of the line with robotic packing. “Packing is just hard work,” says Maguire. “So helping the employees out by automating is the way to go.” He notes that adding more automation to the end of the line at other bakeries is one area of potential growth in the future.

“Our business has continued to evolve over the last five years in many ways, but I would say the most significant would be the way we approach food safety and employee safety,” says Dermody. “We’ve developed a detailed training program for all of our employees with a strong focus on obtaining BRC status and being fully prepared for the FSMA.” The Swedesboro and Van Nuys bakeries are both BRC-certified, kosher and organic-compliant.

“All of our bakeries are audited by independent, third-party food safety auditors and achieve certification annually under the Global Food Safety Initiative (GFSI),” says Dermody. “Our suppliers are GFSI-certified and are also audited by certified ARYZTA auditors. We have a corporate ARYZTA Integrated Management System (AIMS), so all locations operate under the same policies and procedures.”

Yamin notes that the AIMS program extends throughout every bakery. “We wanted to have a step-by-step manual for people to be able to run the bakery to exact specifications,” he says. “So, whether a bread is supposed to rest for 24 hours, 12 hours or 6 hours, it’s all documented.”

From farm to table

Over the past decade, U.S. consumers have grown progressively more interested in food origins. This scrutiny has led to notable upticks in the desire for natural, organic, artisanal products—foods that hearken back to a simpler time. Part of this halcyon picture is a desire for greater grain diversity, and heritage grains will continue to play an up-and-coming role.

La Brea Bakery is ahead of this curve with the introduction of its La Brea Bakery Reserve line in May 2016, baked with single-origin Fortuna wheat grown in Big Sky Country, MT.

“La Brea Bakery Reserve is highly unique in that it utilizes Fortuna wheat, a sustainably grown, heirloom grain focused on flavor and not exclusively on yield,” says Dermody. “It’s the first nationally available farm-to-table artisan bread, and provides an unprecedented level of transparency in the artisan bread industry.” This line also includes pain de campagne and Struan loaves. “The breads are uniquely characterized by their distinct flavors, complex textures and subtle notes,” she says.

La Brea Bakery runs long fermentation for its breads—up to 24 hours—so the Fortuna wheat needed to stand up to that process. According to Davis, not only did it fit the system, it thrived. “The flavor that it generated was truly unique—and enhanced through the longer fermenting process,” he says. “You really have to taste it side-by-side to really get the nuances of it.”

Subtlety is a hallmark of all La Brea Bakery products. “It is our responsibility to stay curious and continue to look at, and define, how thoughtful, nuanced and special a simple loaf of bread can be,” says Dermody.

In what was already a busy year, the bakery also committed to going non-GMO for its entire line of artisan breads by the end of 2016, making it the first non-GMO artisan bread line available in North America. This transition was eased by the bakery’s longstanding work in Europe, where non-GMO is just part of doing business. The first products featuring the Non-GMO Project Verified logo have already hit stores. The bakery also began using only cage-free eggs this year.

“Transparency continues to be an important trend for all food,” says Dermody. “Consumers want to know where their food comes from, how it’s made and what’s in it.”

The move toward heritage wheat for the La Brea Bakery Reserve line introduced the bakery to the business of growing wheat—albeit on a small scale. “It’s growing for quality, not quantity,” says Dermody. “It’s our opportunity to take artisan to the next level.”

The move to non-GMO also opened the opportunity for a packaging redesign to accommodate the Non-GMO Project Verified logo. The new packaging provides an unequivocally clear look at the bread inside. “We wanted to highlight that important step for the brand while also more prominently showcasing the bread in the package,” says Dermody.

Into a sustainable future

Sustainability has long been at the core of La Brea Bakery. “We have a comprehensive sustainability program that addresses environmental practices, sustainable sourcing programs, people practices, safe and wholesome food practices, and community engagement,” says Dermody. “Our bakeries are zero waste to landfill. Additionally, our Los Angeles bakery and Van Nuys bakery have reduced their water usage by 8 percent and 12 percent, respectively, as a response to ongoing drought concerns.”

“We looked at water, we looked at electricity, we changed all of our lighting to make sure that it was up to code and beyond,” says Yamin. “Our focus is to see how we can push toward making every aspect of the operation even more sustainable. Everything is timed. With the lighting, if you’re not in the room, the lighting is off. It’s all those little things that we need to think about.”

While La Brea Bakery has seen tremendous growth and success over time, myriad possibilities await in the coming years. “When I think about the future of La Brea Bakery, I think we’re more than just a bread company,” says Dermody. “We want to be a great food company.”