Just a footnote before I file my impressions for Day 3 in Ghana : it's not always as simple to file copy via the Internet as I envisioned. First, there are occasional power outages, even in our hotels.

Port of call

Just a footnote before I file my impressions for Day 3 in Ghana : it's not always as simple to file copy via the Internet as I envisioned. First, there are occasional power outages, even in our hotels. Although the hotels we're staying at have their own generators, the outages can be disruptive. Also, the wireless connections are not always reliable, so one has to improvise, putting files on a memory stick and then hoping the business center is operational. That said, this trip contains so many experiences and vignettes, it's impossible to capture them all in a daily blog. I hope to do justice to the trip's organizers with a more complete overview later next month.

So, let's pick up where I left off on Sunday. Following our formal meeting (See Day 2) at the Labadi Beach Hotel, the delegates were hosted to lunch sponsored by Olam International Ltd.,which was held outside under some dazzling white canopies. Uncharacteristically, I arrived late for lunch, having focused on my interview with Sylvia Hinson-Ekong, managing direct for the Future Resources Development Ltd., and the rescued young boy, Kuami Richard. Wouldn't you know it, as I left the conference room I could hear the rain coming down with some intensity. So much for a sunny meal. As I approached the outdoor area, the wind really picked up and soon there were scores of servers and chefs running around the patio area, which was open but under a roof.

“Now you'll have something to write up,” Peter Johnson, Euromar Commodities Ltd.'s ceo, told me. Noticing the puzzled look on my face, he pointed to the white tent canopies below the patio area.

Sure enough, one of the white tents, the one that housed the food line, had been lifted up by the wind and flipped over, its metal supports staring up at us uselessly. Luckily, no one was hurt and the hotel crew quickly transferred the food warmers up and onto the patio in short order.

Indeed, this is the beginning of the rainy season, I thought. Appropriately, chocolate desserts finished off the luncheon. After which everyone packed onto the two buses and headed off for a three-hour drive to Elmina Beach Resort.

Upon our arrival and check-in, we met up for dinner and did a roll-call, identifying who we were, what we do and what we were looking to get out of the trip. For the most part, the distinguished group (See the list below) reported that they wanted to see for themselves, up close and personal, where and how cocoa is grown, cultivated, harvested, transported, processed and shipped, as well as what kind of efforts are in place to address child labor issues.

We were also prepped on our visit to Takoradi Harbor , a deep-water port that handles much of Ghana 's cocoa shipments. With the ocean waves literally crashing in front of my balcony window, it didn't take long for me start cutting Z's and fall into a deep sleep.

My Timex wristwatch with an alarm beeped me up at five and quickly cranked out my first day blog. Of course, that's when the wireless issue came up, but no matter, I eventually found a way to send it through the business center.

The group left the hotel about 7:45 , again in two buses. Bus No.1, the one I elected to get on, quickly set a fast pace. Not only was our driver quick, he was a bit of a daredevil. Upon approaching a town that was having a classic Monday morning traffic jam, the driver demonstrated what he had learned at the Ghanaian school of aggressive driving school techniques.

Faced with bumper-to-bumper traffic on the right-lane of a two-lane highway, he simply elected to go British, driving on the left lane and blowing his horn to let oncoming traffic know we had the right-of-way. Amazingly, the maneuver worked and we zipped by rows and rows of cars. The driver of Bus No. 2 opted not to follow us, and as we discovered later, it took them quite a bit longer to reach the harbor.

After roaring into Takoradi Harbor 's security checkpoint, a move that the security guards didn't seem too pleased with, we eventually received clearance to disembark the bus and begin the tour.

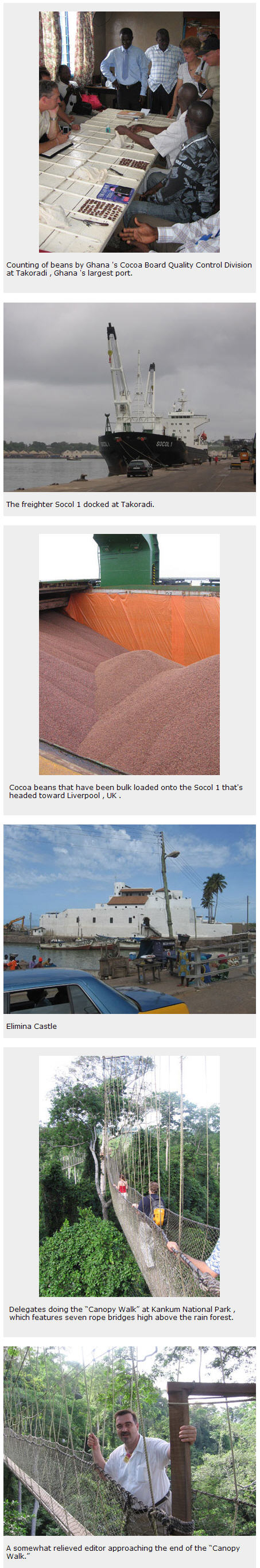

George Okyere, quality control manager at the port for the Ghana Cocoa Board's quality control division, greeted us and proceeded to take us to one of the storage sheds where laborers were loading a flatbed truck with cocoa.

It was amazing to see these workers have a 140-lb. (63.9 kilos) placed on their head and then walk it up a ramp before flinging onto the truck. According to Johnson, who later told me he had talked to one of the workers, the men earn about 75,000 cedis a day, the equivalent of $8.

One look at the chiseled bodies of the manual laborers underscored their toughness and strength. It also drove home the economics of labor in the Third World , although we would later see an example of what mechanization was doing to cocoa shipping.

Our group went into one of the shed where we saw stacks upon stacks of cocoa bags. Okyere explained that every bag is sampled, the inspectors doing empirical analysis for mould, flatness and other defects. Moisture content is also measured.

To prevent infestation, the cocoa bags are fumigated using phosphine gas. Tarps are placed over lots during the fumigation, which typically takes about five days. General fogging using an oil-based chemical is done three days each week as another way to keep the beans insect-free.

From there we proceeded to go to grading office, where samples that are taken are inspected. There are five categories of bean size and three grades. Inspectors weigh out 100 grams of beans and do a physical count, determining how many beans there are in the 100-gram sample. Cutting of the beans reveals whether they've been properly dried and fermented, critical components in establishing grade. After sampling, the bags are sealed and certified according to grade and category.

The group then proceeded via a short bus ride to the megabulk loading areas. In this process, bagged beans are unloaded, opened and then conveyed into a mountainous pile. Again, using plastic tarps, the beans undergo fumigation.

When it's time to load, a front-end loader scoops up the beans and places them into a scaling hopper, which in turn, feeds a enormous, specially built conveyor that transports them into a hull of a ship.

Kor Ritsema, country manager for Unicontrol Commodity – Ghana Ltd., the group responsible for handling all megabulk loading, explained that between 30-40% of all cocoa shipments in Ghana are now being done in megabulk,

Although there's some breakage of beans when the first cocoa beans falls 12 meters into the hull of the shipment, the damage remains comparable to bagged beans, and reportedly, the bulk beans maintain their quality level better than their bagged counterparts.

When Johnson asked Ritsema whether we could visit the ship docked near the warehouses, Ritsema jokingly said we could, but for a slight fee. Recognizing these delegates tended to be hard negotiators, he quickly relented, but told us that boarding was dependent upon the captain.

The captain, in turn, decided he didn't have to worry about any looting from these cocoa and chocolate industry maties and allowed us to visit the ship. As Ron Graf remarked, touring the vessel quickly removed any romance about working on a freighter.

Still, it was fascinating to see the hydraulics at work opening these huge doors and revealing mounds of cocoa beans in the belly of the ship, anywhere between 5,000 and 9,000 tons.

Ritsema says bulk loading is the wave of the future, particularly since it offers efficiencies. Nevertheless, traceability is a something that's lost when thousands of beans are mixed into a huge mound.

Upon conclusion of the tour we jumped into the buses and headed back toward Elimina, this time driving through town and toward the Coconut Grove Hotel for lunch, which was being hosted by Nestle. Shortly before arrival, the clouds parted and the sun came out, revealing what true heat in Ghana can be like.

The setting at the Coconut Grove Hotel, however, couldn't be finer. Nestle's Louise Hilsen, v.p. – government relations, had arranged for an excellent shish-kabob mix of beef, chicken and fish, supplemented by a cooling ocean breeze and the gentle crashing of waves on the beach.

Not sure how much hand Hilsen had in the sun and surf department, but I'll give partial credit anyway.

After the meal, delegates had a choice to make; they could either tour Elimina Castle , infamous for being a point of entry and exit during the slave trade, or trek through Kakum National Forest , famed for its canopy walk, one of only five that exist in the world.

Mr. Adventure, yours truly, after consultation with John Long, Hershey's v.p. – corporate affairs, and Saurabh Mehra, trader with Olam International, decided to shimmy alongside the treetops on nothing but rope and wooden planks.

It was a thrill, although the heat, humidity and nervousness produced a really sweaty Bernie. Okay, so I didn't look down that often, and had to hug a tree once just to reconnect with the earth. Once the color returned to my cheeks, I was fine, honest. More tomorrow.