Company: INFICON

Website: www.inficon.com

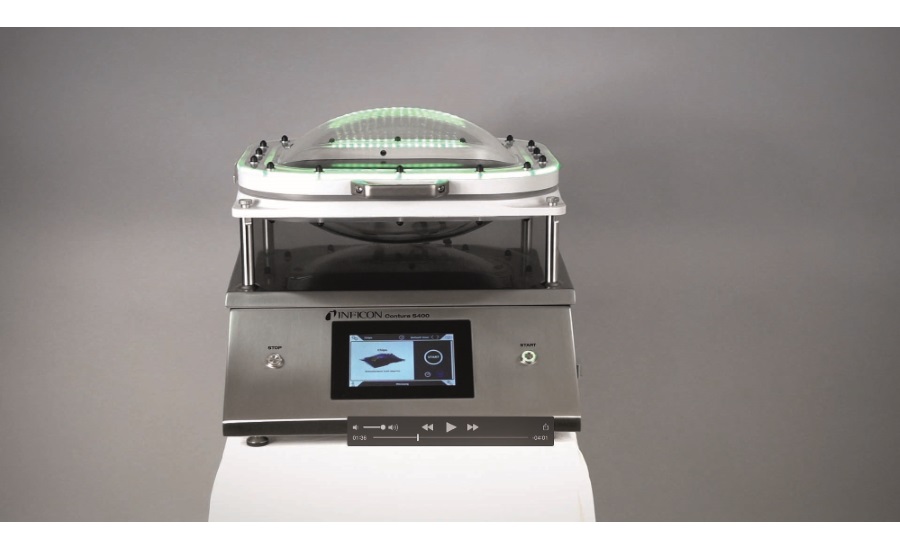

Equipment Snapshot: INFICON has announced the launch of the Contura S400 leak detector to the North American packaging market at PACK EXPO International 2018. The system offers food manufacturers a non-destructive testing approach and serves as a cost-effective, reliable alternative to more traditional leak detection methodologies including water bath testing. It is designed for a range of food applications including coffee, meat and poultry, baked goods, snack foods, confectionery/candy, cheese, grains and cereals, prepared food and produce that are contained in Modified Atmosphere Packaging (MAP) and flexible packaging.

To test for leaks, food manufacturers simply place the package between two unique membranes that create a conformal vacuum chamber which is quickly evacuated. The gas flows through any package leaks into the chamber where it causes an increase in pressure. INFICON’s patented high precision vacuum gauges measure this change to calculate the package’s leak rate and delivers results in seconds. Results are reported via an easy-to-read display screen. Distinctive red and green LED lights incorporated into the machine’s acrylic lid also communicate if a leak has been detected. All results are reproducible.

The ability to provide quantifiable results is just one of several advantages the Contura S400 offers when compared to alternative leak detection methodologies, including water bath testing. A significant benefit is that the system can safely and reliably detect micro and gross leaks, eliminating the risk that a package with a tear or a non-welded sealed seam might be incorrectly identified as airtight.

“Package leaks can have a profound impact on product quality by shortening shelf life and create the potential for food safety issues due to premature spoilage,” said Bill Burnard, business development manager - INFICON, Package Integrity & General Vacuum. “There are a variety of reasons that packages leak, including large pores in the film that result from overstretching. Fine, difficult to detect capillaries can also emerge if product residue gets stuck in the weld seam or if incompatible adhesives are used. Reliable leak detection equipment, like the Contura S400, can help food manufacturers catch compromised packages before they reach the consumer, preventing costly recalls and returns and protecting brand reputation.”

The Contura® S400 can be easily integrated into any manufacturing environment. It is gas independent, eliminating the need for food manufacturers to make any adjustments to production lines. In addition, the stainless steel housing and dirt-resistant protective cap helps satisfy various hygiene requirements. The company’s technical support staff can help manufacturers adapt the Contura S400 to suit their specific needs and determine the acceptable leak rate range, which varies depending on the product being packaged.