The Bottom Line:

- Customers want more sanitation standards

- Quick changeovers are key

- Speed-to-market is also important

Snack food and wholesale bakery companies looking to purchase or upgrade their laminators and sheeters focus most on features and benefits like flexibility, sanitation, and automation, according to companies that manufacture such products.

Quick changeovers, stronger sanitation, and automation are what Ken Hagedorn, vice president of the bakery sector for Handtmann, Lake Forest, IL, heard about the most when he was handling sheeting lines for companies like Rheon and Rademaker; he notes that Handtmann provides dough feeding but not laminators or sheeters, so it’s not part of his current bailiwick.

“They’re all looking for quick changeovers,” he says. “A lot of sheeting lines are wide, starting at 24 inches, and switching from one product to the next can be a very long, detailed process. … With the tool changes, you could be shut down for a long time.” Toolless changeovers can knock that shutdown time from two hours to as little as a half-hour, he adds. “You don’t need a wrench anymore. You can do it with your hands.”

Customers also want laminating companies to provide more stringent sanitary standards, with machines open and accessible for cleaning as well as constructed from stainless steel, Hagedorn says. “We all know that bakery can be messy as hell, especially when you’re doing something like Danishes with all the fat, butter, and fillings,” he says. “In the newer facilities, they’re building them with four drains so they can wash it all down.”

Automated flour fillers are another popular innovation that helps companies reduce staffing, especially useful during a tight labor market, Hagedorn notes. “It automatically monitors the flour hoppers and fills them, so there’s no longer a person walking up and down the laminating line,” he says. “That can be a full-time job for somebody.”

Customers of Baker Perkins, Grand Rapids, MI, and Peterborough, UK, in the biscuit and cracker industry are asking for non-standard equipment that can handle unconventional ingredients and products, according to Keith Graham, business development manager.

“As manufacturers seek innovation in highly competitive situations, attention-grabbing twin-layer crackers involving two distinctive tastes, or two-color products, have become an option,” he says. “They are achieved either by one sheeting machine with a split hopper, or two sheeters mounted one above the other. The two distinct doughs are merged into a compacted sheet ready for the gauge rolls.”

Another choice customers sometimes make is a twin-layer sweet biscuit, with a filling baked between two sheets of dough, such as a Garibaldi biscuit with currants, or a chocolate or praline paste, Graham says. “To add interest and variety, crackers and baked snacks are being developed using non-wheat flours based on lentils, pulses, or chickpeas and from cauliflower or potato dough,” he says. “These are often used to achieve gluten-free products and may also be perceived as being healthier. The possibility of original flavors or textures is another motive.”

Flexibility, speed-to-market, and automation are top of mind for customers of Rademaker USA, Hudson, OH, according to Nick Magistrelli, vice president of sales. When it comes to flexibility, customers typically don’t want a one-size-fits-all line—they want to be able to “take into consideration a variety of processes,” he says. “To justify this investment, customers don’t want to get pigeon-holed. It makes them a lot more confident when they can pivot down the road and produce new SKUs and fill different needs.”

Speed-to-market is another consideration, although sometimes customers’ timeframes outstrip the manufacturer’s ability to produce, and they need to consider the used market instead, Magistrelli says. “Especially in today’s world, where everybody has ongoing and, in many cases, growing supply-chain issues,” he says. “When your clients can deliver in that speed-to-market scenario, that provides them an advantage over the folks on the other side of the table.”

Finally, with the current rate of employee turnover, automation has become a top priority—but snack and bakery companies need to consider this step carefully, Magistrelli counsels. “When they invest in automation, they have to live with that automation,” he says. “Many times, they weren’t ready for it. They had to make a change internally in their culture to respond to the lack of reliable workforce. They turn to vendors and equipment manufacturers to provide an answer to their problems. We’ve got to be a reliable business partner to support that.”

David Moline, vice president, sales and marketing for Moline Machinery, Duluth, MN, says sanitary requirements for snack and bakery customers have advanced with the trend toward meat fillings, especially in breakfast items. “There’s a lot of innovation going on in the breakfast space, for microwaveable, toastable things,” he says. “That places specific demands when sheeting is involved. … We’re doing everything we can to keep pace and exceed what our customers are looking for.”

AMF Bakery Systems, Richmond, VA, has been hearing from customers about the machinability of products like artisan and premium-quality bread products, with high water percentages and resulting stickiness, and the company has engineered products to match those demands, says Diana Boxey, global marketing director.

Company

AMF Tromp

Featured Product

SFA Artisan Bread Line

The newly introduced SFA Artisan Bread Line from AMF Tromp, showcased at IBIE, can handle both common and specialty doughs with low stress to maintain dough properties and allow for “maximum personalization,” and the system provides quick product changeover and resulting flexibility, Boxey says.

“Engineered with the latest in sanitary design, the SFA sheeting line produces a wide variety of artisan style breads, baguettes, ciabatta, batard, and many sourdough breads for producers looking for flexibility in producing multiple types of breads on a single line,” she says. “This line combines our initiatives around sanitary design and sustainability by reducing water usage as well as reducing waste.”

Features of the SFA line include a stainless steel, hygienic frame design with closed, welded bodies that use industry-standard food plastics for maximum safety and minimum water usage, Boxey says. “The operator-friendly design ensures quick, easy access for sanitation with toolless features like belt relaxers for under belt cleaning and drying after sanitation, as well as washdown flour dusters,” she says.

Company

Baker Perkins

Featured Product

TruClean

Baker Perkins offers the TruClean sheet forming and cutting lines, which can process a wide range of dough types, from crackers to hard, sweet biscuits, Graham says, adding that the company can configure production lines to suit laminated or straight-sheeted process requirements—or both, if a unique combination laminator is used.

“The sheet and cut process is traditionally used on hard and semi-sweet products such as Marie and Petit Beurre biscuits, although there is increasing cross over into enzyme-raised crackers, baked snacks and softer dough products where a lighter texture is needed,” Graham says.

Company

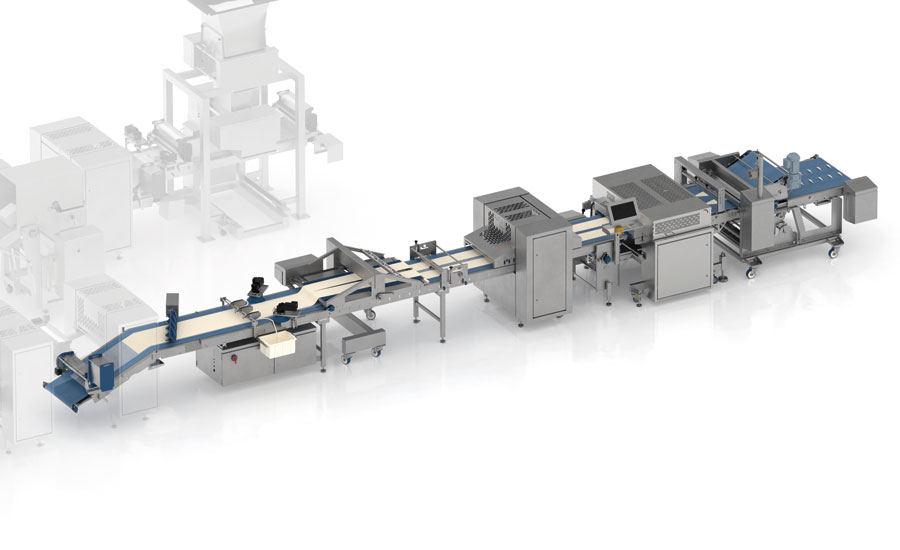

Rademaker USA

Featured Product

Radini

Rademaker latest offering is the Radini system aimed at mid-range bakeries, which retains the quality features of legacy Rademaker equipment, such automatic controls, while providing more of a capacity limitation, Magistrelli says. “We think it’s an answer for that bakery that’s not retail-level anymore, they’ve grown up a little bit, but before they take the plunge to get into the industrial side of the marketplace,” he says.

The Radini takes less time to produce, more like three to six months rather than six to 10, and is delivered at a price point that Rademaker hasn’t traditionally offered, Magistrelli says. “It’s substantially less in price point and much quicker in delivery time,” he says. “You see a lot of that in the industry now—customers have to fill orders and get business lined up based on timing and price point. We’re trying to match that.”

Rademaker is doing so without sacrifice product quality or range, Magistrelli adds, as the Radini can be set up to deliver such offerings as artisan breads, doughnuts, pastries, Danish, cinnamon rolls, pepperoni rolls, and more.

Company

Moline Machinery

Improvements to dough tensioning, hygienic design, automation

Moline Machinery has upgraded its existing laminator and sheeter lines without introducing anything brand new, Moline says. “We’ve added some features, especially on larger sheeting lines with multiple gauging stations,” he says. For example, “we’ve got an automated dough-tensioning monitoring system that makes tweaks … so that the sheet doesn’t become bunches or stretched, so that it affects the final weights of products.”

The company also had made improvements to hygienic designs for equipment that has to be fully washed down on a daily basis, Moline says, including quick belt removal and easier access points, “so they can dry them and get the line cleaned and turned around much quicker than lines that wouldn’t have such features.”

Lastly, Moline has streamlined its delivery systems for automated flour dust dispensing, using silo dusters that can be integrated with bulk four systems so they no longer need to be manually filled. “Where that can be a task for a person, bakeries have seen the value in automating the delivery of their dusting flour,” Moline says. “We’ve got a fully automated system that hands it off from the flour delivery system to the actual dispensing system.”