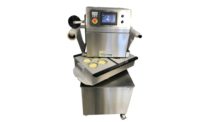

Company: CTC International

Website: www.ctcint.com

Equipment Snapshot: CTC International introduced its mode 800-PB-VF- 36 heavy duty compact semi-automatic splicer engineered to operate in line with converting processes up to 36” wide.

This ergonomically designed machine allows non-stop production for rolls up to 36” diameter and weighing up to 900 pounds.

The splicer loads rolls directly from the floor without requiring any additional material handling equipment, by using a turreting roll lifting concept.

A built in web festoon allows the operator to load rolls and make manual splices while the process is running, providing non-stop production. The included splice table has and a cutting slot for the operator to trim the expired and new webs, and a convenient integral tape dispenser.

The machine is engineered so that just one operator can do all roll loading and splice prep.

Machine can be application engineered for a wide range of roll sizes, web tensions and web dynamics. A CE compliant version is also available.

Standard features include:

- Precise tension control via festoon feedback to pneumatic braking system

- Unitized Construction - all parts mounted on a solid base for easy moving

- Turret design for easy roll lifting directly from the floor.

- Splice table pivots up for roll loading and down for access to the splice prep.

- Industry Standard PLC Control

- Convenient Tape dispenser integrated into splice table

- Splice prep signal tells operator when to load new roll

- Web Break Detector