Bakery and snack warehouse operations have little room for error when it comes to delivering fresh goods to market. Luckily, there are new ways to manage inventory in and out of the warehouse by using traditional equipment, autonomous vehicles, and automated picking solutions. These innovations also improve ergonomics and employee safety.

Sustainable power

Sustainability is an important consideration for manufacturers of warehouse equipment, which has resulted in the growing use of lithium-ion batteries in forklifts. These batteries offer many advantages over lead-acid batteries. They are maintenance-free, sealed units, eliminating the need for battery watering, and can be opportunity charged during operator breaks. They do not emit gas during charging and offer greater energy efficiency, according to Craig Bruns, vice president of customer support, Crown Equipment Corp., New Bremen, OH.

Crown Equipment recently introduced a line of lithium-ion-powered forklifts. “The Crown V-Force Lithium-Ion Energy Storage System (ESS) is fully integrated with the truck, which allows the display to show battery discharge levels and alerts the operator before truck operation is stopped. The system includes a modular V-Force charger, as well as a battery management system that extends battery life by preventing operation outside of warranted conditions,” Bruns says. Crown Equipment also has introduced the V-HFM3 Series of modular battery chargers that can be configured to charge lead-acid and V-Force lithium-ion batteries.

Yale Materials Handling Corp., Greenville, NC, offers the Yale Power Suite, a broad range of power options across its line of lift trucks. The company offers warehouse managers the choice of hydrogen fuel cells, lithium-ion batteries, internal combustion engines and lead-acid batteries. This provides them with a solution built solely around their business and sustainability requirements, rather than constraints such as limited power options or power sources.

Hyster Co., Greenville, NC, has introduced the J60XNL counterbalanced lift truck with integrated lithium-ion power. “We designed the J60XNL from the ground up to take advantage of the form factor of lithium-ion, freeing space in the operator compartment and reducing truck weight for ergonomic and efficiency benefits,” says Addie Watson, industry manager. The lithium-ion battery power benefits include zero maintenance requirements, no hazardous chemicals and off gassing, and full charging in about one hour.

Advanced innovations

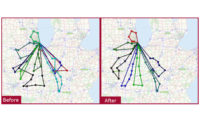

Another trend worth noting is the rise of lift-truck telematic solutions. For example, the Hyster Tracker provides instant fleet insights including impact alerts and checklist notifications. It also restricts access to operators with proper certification and training through keycard access. “Equipment diagnostics trigger automated service calls via engine, transmission, hydraulic and electronic system monitoring,” Watson says.

As customer demand for variety grows, bakery and snack producers may be straining to keep up with SKU proliferation and warehouse space requirements, notes Shelley Bell, industry marketing manager at Yale. “In response to this need, the Yale MO25 multi-level order selector has an operator platform that rises, allowing access to higher-level storage locations. This allows for new slotting strategies that can boost capacity by 30 to 140 percent in the same footprint.”

Manufacturers also are adding features that improve ergonomics. For example, Crown Equipment recently introduced the D4 Armrest as an option for its sit-down counterbalance forklifts. It features a large surface area with a breathable pad that pulls moisture from the operator’s arm. Its integrated horn button, built-in grab handle and up/down and fore/aft adjustment allows operators to comfortably operate the forklift in a more productive manner.

Robotic advancements

Autonomous lift-truck technology has improved markedly over the past few years, according to Alec Hicks, group director, solutions design for Ryder, Miami, which operates 55 million square feet of warehouse space throughout North America. While pallet trucks and forklifts are still predominantly used for transporting case and pallet loads, the technology in the vehicles is much more effective today.

“The keys to this effectiveness include improved mapping and navigation technologies, which make autonomous mobile robots (AMR) better at navigating. Improved 3D vision technologies and machine learning capabilities are improving the ability of these robots to pick and put-away in a dynamic warehousing environment. Also, human machine interface and collision avoidance technologies make AMRs safe to use,” Hicks says.

Autonomous vehicles are now easier to integrate into operations to supplement a limited labor force. Improved safety and productivity are among the benefits of using these vehicles in bakery and snack warehouses “Inexperienced employees can cause product and facility damage, put food quality at risk, and decrease productivity. In contrast, mobile robotic solutions are able to detect obstacles during movement and pallet entry/exit, reducing damage and additional costs,” Bell says.

Hyster robotics utilizes infrastructure-free navigation technology that maps existing structural features to self-locate and navigate without the need for laser reflectors, guide wires or magnets. Operations can run with zero, partial or full integration with facility warehouse systems. “Since Hyster robotics are standard lift trucks outfitted with robotic technology, they can switch from automatic to manual mode and allow operators to take charge, helping to accommodate changing warehouse demands,” Watson says.

More and more, warehouse picking is being done by robotics, especially given the current labor shortage. Picking grocery items, particularly bakery and snack foods, via robotics requires two capabilities: the ability to handle high variability and to do so with a delicate touch that will not damage the product, according to Austin Harvey, senior product manager, Soft Robotics, Bedford, MA. The company’s SuperPick combines a 3D vision system with patented soft-grasping technology to fill grocery orders.

Harvey says the system offers improved throughput. “SuperPick is designed with a high-speed industrial robot to deliver hundreds of picks per hour.” It also increases order accuracy. “SuperPick pairs the Soft Robotics 3D Vision System with additional grasp detection and bar code sensing to ensure that orders are accurately filled and delivered as expected.”

Rapid robotic handling enables faster order fulfillment, which helps bakery and snack producers maintain optimal product freshness and shelf life, according to Derek Rickard, distribution systems sales manager at Cimcorp Automation Ltd., Grimsby, Ontario, a manufacturer of robotic order fulfillment solutions. “Automated order picking also helps them better manage seasonal peaks. Some facilities—especially those struggling with the current labor shortage—try to hire seasonal staff to get by, but that comes with other challenges in providing proper training.”

“But an automated system, particularly one with a modular design, offers flexibility and scalability. Facility managers can adapt their levels of automation according to fluctuations in inventory and order volumes and keep their operations running at their best all year round.”

Future-proofed integration

Total warehouse systems are available to integrate this wide range of equipment. Westfalia Technologies Inc., York, PA, offers a high-density automated storage and retrieval system (AS/RS) that can store and retrieve layers and cases from inventory. Combined with the company’s Warehouse Execution System (WES), Savanna.NET, the AS/RS provides users with full control over material flow, according to Dan Labell, president.

The combination of the AS/RS and Savanna.NET allows warehouses to implement just-in-time (JIT) strategies. “Facility managers do not have to prepare orders far in advance and can keep items in storage within the automated system. When a truck arrives, operators initiate the order fulfillment process via Savanna.NET, which directs Westfalia’s storage/retrieval machine (S/RM) to pick and deliver the order to the appropriate area for loading,” Labell explains.

Looking ahead, Rickard sees a convergence of robotics, software and the Internet of Things in the warehouse. This “cyberphysical” environment will feature software that directs robots in product storage and retrieval. “Sensors capture data on robot performance, which are sent back to the software, essentially creating a feedback loop. Facility managers can then make timely adjustments to readily pivot to sudden order changes and further improve warehouse operations.”