New Equipment

The palletizer features a FANUC CRX-25iA collaborative robot.

Read More

Mitsubishi Gas Chemical releases first-ever, PFAS-free oxygen absorber

The technology will debut at Pack Expo in booth SU-7490.

July 14, 2023

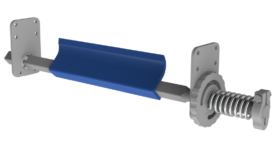

Flexco introduces FGP Food Grade Primary Cleaner with external spring

The cleaner is ideal for use in most sanitary food processing applications.

July 13, 2023

Multi-Conveyor builds 1:2 conveyor system with simplistic divert and pin-pull interlocks

The conveyor system was built for a flexible snack bag product.

June 28, 2023

Developing and testing prototypes can help fine-tune snack and bakery production

Various testing methods and tools help producers refine snack and bakery products and processes.

May 17, 2023

Munson releases Cylindrical Plow Blender for problematic bulk materials

Plow Blender is best for herbs, spices, powders, and sticky materials like cake mixes.

April 25, 2023

Lean manufacturing can streamline snack and bakery operations

Lean manufacturing as a team effort can yield improvement across snack and bakery operations.

April 21, 2023

Ross releases V Cone Tumble Blenders for high-accuracy mixtures

Control panel includes 7" color touchscreen display with a recipe system.

April 20, 2023

Pearl Technologies introduces ‘value’ zero-clearance punching units

The equipment places hanger holes and tear notches in snack and bakery pouches.

April 19, 2023

Syntegon to showcase flexible systems for cookies, bars at interpack 2023

Company's line flexibly packages cookies, crackers in mono-material trays and flow wraps.

March 29, 2023

Get our new eMagazine delivered to your inbox every month.

Stay in the know on the latest snack and bakery industry trends.

SUBSCRIBE TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing