Bulk container

Bulk container

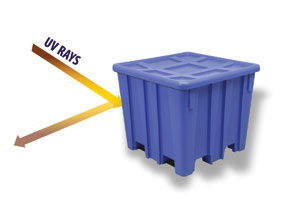

The P-433 Ship Shape reusable, water-resistant bulk container from Meese Orbitron Dunne Co. resists ultraviolet light to help safeguard light-sensitive products, including food, from degradation due to light-induced chemical reactions. Featuring a three-pronged approach, the bulk shipping and storage container is rotationally molded from 100%, UV-inhibited, high-density polyethylene (HDPE), boasts a uniform wall thickness for opacity and comes in a choice of colors that help scatter sunlight. In addition, the container handles payloads of more than 1,000 lb. in 35 cubic ft. of space on a standard 44 x 44 in. footprint with four-way lift truck access. Custom accessories include fork safety tubes, casters, hinged inspection panels and molded-in tracking numbers and graphics.

800-829-4535 • www.shipshapecontainers.com

Controller

Controller

Unitronics Ltd. introduces its first Jazz 2 Series controller: the JZ20-R31. With 48-K (virtual) Ladder Logic memory, 30 times faster performance and a built-in, mini USB (universal serial bus) programming port, the new model provides industrial control processes with more power, speed and functionality for the same price as its standard Jazz series counterpart. Features include 16 digital inputs, including two inputs that can function as high-speed counters or normal digital inputs; two digital/analog inputs; two analog inputs; 11 relay outputs; and a full-function HMI with a two-line LCD text display that shows up to 60 user-designed screens and a 16-key keypad. The multilingual display supports more than 15 languages and 20 graphic symbols.

866-666-6033 • www.unitronics.com

Horizontal flow wrapper

Horizontal flow wrapper

Campbell Wrapper Corp.’s washdown-duty Revolution horizontal flow wrapper is designed for a variety of applications, including bakery, confectionary and frozen foods. It features a sanitary, modular design and stainless-steel, hard-coat anodized aluminum and USDA-approved materials for contact parts. The servo-driven wrapper can handle polypropylene, cellophane, film-coated paper, laminates, high-density polyethylene, polyethylene and shrink or polyvinyl chloride film and wraps 100 to 600 packages per minute, depending on product size and the packaging material used. Options include automatic film splicing; out-of-position product/no-cut; no-product/no-package; high product detector; and slack web detector.

920-983-7100 • www.campbellwrapper.com

Rotary chamber machine

Rollstock’s RC-300 rotary chamber machine features a 304L stainless-steel modular frame capable of accepting a variety of chamber configurations (widths and lengths) and sealing profiles (single, double or custom seal impressions) and sealing widths up to 24 in. A patented constant-temperature sealing system enables the model to seal through thick bags, contaminants, folds and wrinkles. Using state-of-the-art micro-processor control and a 10-in. touchscreen display, the RC-300 offers easy operation and monitoring with pre-set storage capabilities. In addition, it provides control over sealing temperature and time and pneumatic control over sealing pressure.

800-295-2949 • www.rollstock.com

Depositor

NuTEC Manufacturing’s C-Frame depositors are designed to improve the way processors deposit fillings for appetizers, multilayered products, rolled or wrapped product, stuffed sandwiches and more. The company’s unique feed system uses a rotating spiral that gently moves the product to the rotary vane pump. Bridging and overworking are eliminated because the product is neither rolled nor tumbled, providing excellent particle definition and piece identity in finished products. Deposit sizes of up to 1½ thick can be achieved, with certain models offering 45,000 deposits per hour. In addition, a C-frame design enables the equipment to fit into existing production lines.

815-722-2800 • www. nutecmfg.com

Collator/case packer system

Collator/case packer system

The Cobalt 3100 Series Easy Pack system from Cobalt Packaging uses moving tape head technology to bottom-seal corrugated cases and manually pack products. The system collates, counts and neatly organizes pouches, bags and cartons for easy case packing by the operator. According to the company, the Cobalt collator makes packing more efficient and ergonomically friendly over traditional turntable packoff lines, eliminating repetitive twisting motions and simplifying product pickup and case packing by the operator. Case counts are selected on the control panel, eliminating counting errors. System changeover from size to size takes 2 min. Made in the U.S., the system is built to withstand the heavy use of three-shift operations.

616-258-6060 • www.cobaltpackaging.com