International Food Products, a food flavor and ingredient manufacturer, was moving and expanding operations to a new $20 million facility in St. Louis, MO. They approached EPIC Systems, a local design/build engineering firm, about providing pre-engineered sanitary blending skids equipped with multiple batch mixing systems for both their liquid and powder products. EPIC designed, built and integrated the sanitary process skids. In addition, EPIC integrated and expanded seven liquid and powder packaging lines.

International Food Products, a food flavor and ingredient manufacturer, was moving and expanding operations to a new $20 million facility in St. Louis, MO. They approached EPIC Systems, a local design/build engineering firm, about providing pre-engineered sanitary blending skids equipped with multiple batch mixing systems for both their liquid and powder products. EPIC designed, built and integrated the sanitary process skids. In addition, EPIC integrated and expanded seven liquid and powder packaging lines.

To meet growing market demand, International Foods purchased the brownfield site of a closed Ford Motor Company plant in St. Louis. Partnering with EPIC Process Systems, they built a new facility and expanded production for both liquid and powder food product lines. The processing and pack out portions of this project were the heart of the $20 million expansion. The impact of this project included:

- Successful start-up at the new facility was on time and budget

- Product offerings and production capacity nearly doubled for the company

- Higher automation in new systems allowed better tracking and quality control of products

Key features & core challenges

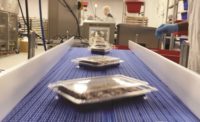

EPIC build process systems that were designed to meet Title 21 CFR Part 110 cGMP guidelines and were built using sanitary fabrication methods, ensuring the integrity of the systems. The blending systems, as well as the packaging equipment, was installed turnkey, allowing for optimal uptime in the facility. The turnkey installation also included facilities design, utility expansion, and construction management all executed by EPIC.

In addition to the design/build of new equipment, EPIC coordinated the integration of existing process equipment into the new facility. With that, EPIC had to balance the expedited design/build schedule with the installation and integration of all process equipment at IFP's production site. Upon the completion of the install, EPIC trained new employees on the expanded manufacturing process equipment.

All of this had to be completed under a fast-tracked schedule. In essence, EPIC systems designed the new process equipment, coordinated the relocation of existing equipment, worked in conjunction with other contractors, managed their subcontractors, trained International Food Products' employees, and did all of this on time, so that International Food Products could be in production ASAP.

Solution summary

Starting early in the project planning process, EPIC’s project management set the direction for process facilities design and associated power and utilities. EPIC completed the process and physical design for each of the processing areas, efficiently using space to allow room for future expansions within the facility. All process and packaging equipment were required to comply with food and beverage sanitary requirements Title 21 CFR, Part 110 cGMP guidelines.

While site and facilities construction was underway, process system fabrication at EPIC’s sanitary fabrication plant was occurring simultaneously. Process systems were constructed as self-contained modules. Finished modules were shipped to the International Food Products plant, followed by a fast startup within three days of arrival. EPIC’s offsite modular build approach was critical to the success of meeting a stringent project schedule. Each sanitary batching and blending system went through in-house, Factory Acceptance Testing (FAT) to ensure a trouble-free start-up during installation.

EPIC's project management team coordinated all utilities installation and integration on the heels of facility completion to eliminate potential schedule creep on process system installation. A team of EPIC’s in-house automation engineers was on-site throughout installation and commissioning. Their presence helped ensure the process and packaging systems were running at specified parameters. EPIC also assisted in training plant personnel on all new operating systems associated with the new plant equipment.

The collaborative project resulted in a successful startup, allowing International Foods to increase production, meeting the demand for their growing product lines. After the project was completed, Tony Armitage, VP of purchasing at IFP, commented on the success of the project.

"Our company made an investment in a world-class manufacturing facility," Armitage said. "It's an astonishing facility. It's the best in the industry."

About EPIC Systems

Founded in 1995, EPIC Systems is a leading supplier of turnkey manufacturing solutions including modular process skids, machine vision systems, packaging lines, and automation systems. EPIC specializes in designing and building sanitary process systems for manufacturers in the food and beverage, pharmaceutical, and consumer products industries.

About International Food Products

IFPC has been sourcing, shipping, packing and providing top-quality ingredients to their clients since 1974. The company has maintained strong relationships with suppliers over the years and built a team of ingredient experts and food scientists to help their clients produce quality food products.