Snack food and wholesale bakery companies looking for new or upgraded belts, conveyors, and associated equipment are looking for options that are more compact, offer easier cleanability, permit greater automation, have faster delivery time, the welcome the ability to handle gluten-free and other specialized products, among other qualities.

Industry perspectives

Compactness and the ability to fit in different configurations is high on the list for customers of Intralox, New Orleans, says Achraf Elhassouni, global product manager. “Bakeries are seeking efficient layouts when designing or upgrading existing facilities,” he says. “Space-saving and flexible equipment becomes paramount in this process.”

Key Technology, Walla Walla, WA, hears from customers wanting to bolster automation, says Jim Ruff, vice president of process systems and integrated solutions. “More customers have fewer people in their plants, so more automation is required—whether it’s automatic gates or integrating system controls,” he says, adding that it has become even more critical during COVID-19 and the need to social distance.

Customers of Flexco, Downers Grove, IL, have been asking about automation for the past few years due to labor shortages, says Todd Stewart, industry manager. “There’s a lot more automated equipment where you can have fewer eyeballs on it, fewer people watching to see if something bad is about to happen,” he says. “There’s a growing trend of overall automation, from mixing to ramping to packaging, and out the door, where virtually nobody is involved.”

Flexco also has observed the increase in gluten-free and other healthier trends like nuts and seeds baked into breads, Stewart says. “Those seem fairly constant and growing still, especially globally,” he says. “It’s on a larger scale than before, which can cause issues within baking systems.”

Paul Kuharevicz, sales project engineer, Dynamic Conveyor, Norton Shores, MI, says his customers seem more concerned about delivery time for machines. Where in the past snack and bakery makers might be fine with a six-month lead time, now it’s closer to six weeks, he reports.

The ability to easily remove parts of machines for cleanability has been a key component for customers of Dorner, Hartland, WI, according to John Kuhnz, vice presidentz, engineered solutions. “We get more of a drumbeat of folks trying to incorporate CIP systems right into the conveyor,” he says.

New and improved features

Ashworth, Winchester, VA, has rolled out the SmartSpiral, an app for tablets and phones that allows a plant manager, or even an off-site corporate executive, to have access to the heartbeat status of the equipment. The system can pull from multiple pieces of equipment and multiple locations over time, says Jonathan Lasecki, director of engineering.

“It’s a tool to provide predictive maintenance planning rather than reactive maintenance,” says Bryan Hobbs, director of service, Ashworth. “It’s something we’ve had for a few years but continuously try to improve and offer newer features. We’ve developed algorithms for calculating belt tensions, and additional sensing devices to provide feedback on performance.”

Ashworth also has upgraded its half-century-old PosiDrive system to eliminate vibration and jam-ups, handle heavier loads, reduce downtime, and increase efficiency. The company has also released a new High Density Mesh conveyor system that uses tighter, smaller loops and can more easily convey smaller products at faster speeds. “If you allow a reduction in the belt weight to carry more load, you get more throughput, as well,” Lasecki says.

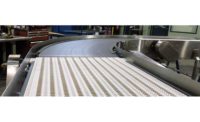

SideDrive Conveyor Co., Souderton, PA, which spun off from NCC Automated Systems in January, provides sanitary spiral and long-run transfer-less conveyors that can accommodate as many drives as necessary, creating layouts that wouldn’t otherwise be possible because belts would break with only one drive, says Kevin Mauger, president. “This is underserved technology that we have developed,” he says. “The No. 1 thing you’re fighting is tension. The No. 1 cause of tension is curves. Spirals are the most-demanding belt application.”

The side drive design enables a company to build a spiral without a cage, which is cleaner, less costly, and allows for less-complex layouts, Mauger says. The other key benefit is the ability to run the belt as long as desired, he says.

Intralox also offers a newly designed side-drive technology allowing for greater layout flexibility and easier maintenance, Elhassouni says. The design enables unique configurations and eliminates transfers between equipment, all while being fully washdown capable. “Fewer transfers means substantially reduced product damage and loss,” he says. “Yield loss due to transfer challenges can be dramatically reduced, and product quality can be significantly improved.”

Key Technology has introduced the Zephyr, a horizontal motion conveyor that reportedly handles product more gently to preserve quality. Zephyr also offers improvement to sanitation, Ruff says. “You don’t have a belt that rolls underneath the product and comes back, and all these surfaces moving relative to each other—a lot of pieces and parts that are moving. Cleanup is much quicker, and maintenance is much lower.”

Flexco has released the FGS food-grade secondary belt cleaner, which attaches itself to a conveying system and helps to remove residual carryback product that’s stuck to the belt, Stewart says. Many companies use homemade solutions for this that don’t automatically re-tension to the belt, whereas Flexco’s solution does so through a spring mechanism. In addition, the blades snap onto a bar, rather than being mechanically attached, making maintenance easier.

“Depending on the type of baking product, earlier in the process you can have stickier, raw dough coming out of a mixer into a hopper and getting put into a divider,” says Stewart. “If any of that material adheres to the belt, it becomes dried and hardened. If it were then to flake off into fresh doughs, it can creates hard spots in a baked product, which is an unsavory experience.”

Dynamic Conveyor continues to refine its DynaClean conveyor line, which includes a modular or flat conveyor that can be shortened or lengthened as needed. The company offers a mixing table conveyor that automatically and homogenously blends together raisins, sesame seeds, M&Ms, and other inclusions, Kuharevicz says. “When it falls onto that conveyor, it takes the mixer out of the equation,” he says.

Dorner has refreshed its product line with the Aquagard conveyor system that Kuhnz says is ideally suited for snack foods and bakery items. The system has a “tip-up tail” that allows for faster access to the inside of the frame for an inspection, wipe, or washdown. Components have been reengineered, with reduced horizontal surfaces and a shift from tubular to formed angles.

Kuhnz notes the product has a proprietary chain with a roller bearing embedded in the middle that reduces both the number of transfers and number of motors required to drive the conveyor. “The goal with everything Dorner does is to try to come up with a product line that has little to no maintenance. They kind of manage themselves.”

The COVID-19 pandemic has led to a run on the round belts produced by Dura-Belt Inc., Hilliard, OH, according to Jim Hammond, president. Those have been used in fulfillment centers from Amazon to Walmart and CVS, moving snack and bakery products—along with many other types of SKUs. The company sells through distributors, and its belts and conveyors end up in plenty of snack and bakery facilities, he says.

IPCO, Totowa, NJ, has released the Compact Belt Tracker, which works virtually with any belt edge detector system on belt widths from 600 to 3,000 millimeters to manage tracking, which it does by tilting the belt using a linear actuator, says Marko Leber, global product manager, food. “As the conveyor moves, a deposit of graphite is delivered onto the inside of the belt,” he says. “This reduces friction for optimum performance and increased belt life, and protects against rust caused by condensation or general humidity.”