Bakers and snack makers seek ovens and proofers with advanced capabilities

When selecting ovens and proofers, labor savings and remote monitoring are at the top of bakers and snack makers lists.

Courtesy of Ashworth

Labor savings, ease of cleaning, and remote monitoring capabilities are top of mind for potential customers of ovens and proofers in the snack food and bakery industries. Also important is the ability to partially bake (or parbake) items and then finish them later, according to manufacturers of equipment and technology.

Customers of Revent are focused on labor savings the most, according to Daniel Florencio, senior director, Americas.

“Prices have skyrocketed, and finding labor is difficult,” he says. “Anything that can minimize [the need for labor] or let you maximize what limited labor you have is something customers are in need of.”

Partly for that reason, parbaking frozen items has become more common, Florencio remarks.

“It’s tough to find scratch bakers for grocery stores, but there’s still a demand for fresh product,” he says. “You can do all your baking on a Sunday or Monday and then bake off products throughout the week. A lot of grocery stores have been retreating from fresh baking and moving to bake off.” He adds the company has introduced the German brand Wiesheu’s convection oven in the U.S. to address this need.

Similarly, Chris Trinch, senior product development manager at Ashworth, says he has noticed a fair number of customers adding a microwave oven at discharge of their existing oven to speed up the line.

“They get the product cooked on the outside and run it through the microwave to cook it on the inside, very quickly,” he states. “They get the shell correct, and that finishes the bake in the middle. It’s a much quicker process,” adding that Ashworth’s Cleatrac belt can be used in that type of application.

Automation technology is increasingly prevalent throughout bakery environments.

“They need to automate at different stages of the bakery,” says Raymond Nogael, marketing and business development vice president at TMG, parent company of Mecatherm. “They need to automate because it brings many benefits.” Centers of automation include ovens and provers, Nogael says, because producers have a need to optimize productivity and consistency.

“If you go out to the proofer, and you put all your stuff on the rack—and then you need to go to the oven—some people will take more time than others,” he says. “Some people will wait a few minutes. And then you will not have the same quality, and you will not have consistency.”

Trinch says he has also noticed cleanability coming up more in conversations with customers, and Ashworth is working to upgrade its belt technology in that regard: “It’s one of those things that’s difficult to resolve. Basically, you need to burn off the product on the belt. There’s not a good way to clean it, other than that.”

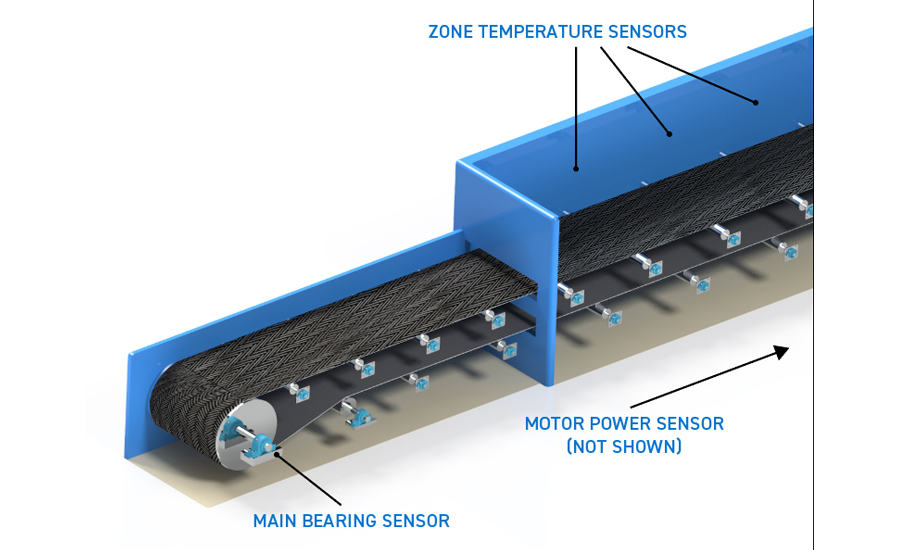

Also, end users have been asking for more remote monitoring, says Jennifer Schneider, global marketing manager for Ashworth. “They want a better plan for maintenance instead of, there being any kind of problem in the system, that stops in the middle of production,” she says, adding that Ashworth offers patented sensors for this purpose as part of the new monitoring system for the Smart Oven line: “There’s a number of sensors that can be customized.”

Vision detection, and other inspection technology installed along the line, is another increasingly common request. Yuegang Zhao, chief commercial officer with KPM Analytics, says such technology can help reduce lost product and save revenue.

“In the baking and snack industry, moisture content is a major factor in product quality; in-line moisture analyzers can help the operator make sure their oven is balanced and also whether they have the right to moisture at the final inspection point,” Zhao offers. We offer online NIR moisture sensor series and thermal imaging cameras that can be incorporated with our vision inspection system to simultaneously measure these important quality aspects. We also offer applications to detect unwanted foreign materials at virtually any processing phase.”

Improved sanitation has been top of mind for customers of Baker Perkins, says Mark Glover, product manager for baked products and food extrusion, adding that has prompted the company to design its ovens with large doors every 2.1 meters “to allow sanitation crews easy access for vacuuming out crumbs or removing product that has fallen off of the oven band.

Other priorities for Baker Perkins’ customers have been simple operator adjustments and repeatable baking profiles that can be achieved with programmatic logic controllers (PLCs) and human-machine interface (HMI), Glover says, as well as expanded capabilities to garner visibility, information and statistics on all of their equipment.

“To satisfy this need, we have implemented Industry 4.0 screens on the HMI,” Glover comments. “This provides operators and maintenance employees easy access to electrical schematics, drawings, spare parts lists, operational information, preventative maintenance prompts, manuals, etc. Finally, to help with troubleshooting, all our panels are equipped with Ewon wireless devices to allow Baker Perkins remote access.”

Ovens and proofing equipment are getting increasingly complex and technical, producers likely have noticed. To help companies wrangle with complexities faced in installation and operation, GEA has been giving customers the option of having their modules preassembled at the company’s facility in Verona, Italy.

“The aim of plug-and-play ovens is to speed up the installation process, in order to reduce production downtime at the customer facility,” says Mario Da Ros, senior director of project management at GEA. “Preassembled ovens are a great way to ensure a high-quality installation phase of our ovens, given that it is mainly carried out at our own facility.”Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!