Company: MECATHERM

Website: www.mecatherm.fr/en_index-en.html

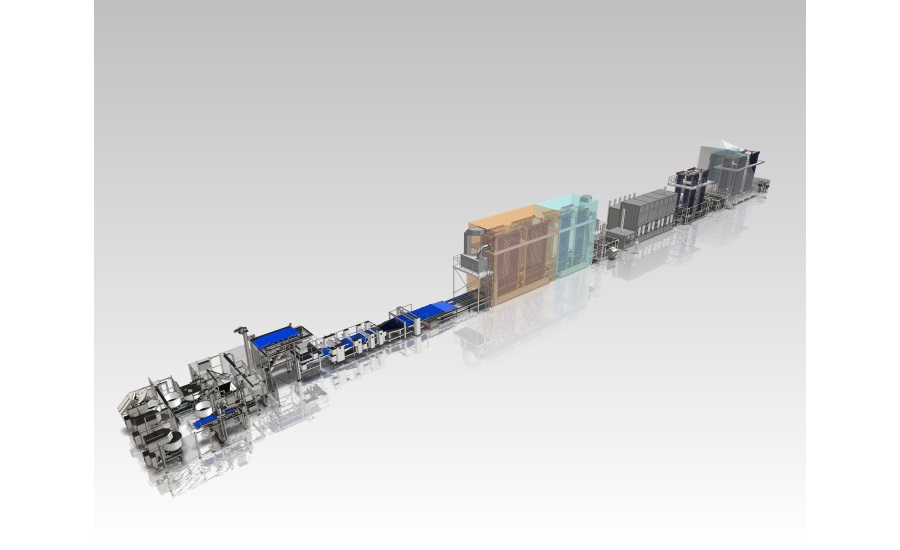

Equipment Snapshot: Thanks to over 50 years of experience in crusty bread, and after years of research, MECATHERM, a pioneer and world leader in the industrial baking segment, has designed and developed a new process, the HQ process. This original industrial process is unique on the market, easy to manage from an operational viewpoint, and can be used to produce artisan-quality bread for approximately the same cost price as standard bread.

This solution allows the baking industry to meet consumer demands and increase their operating results.

MECATHERM can propose its innovative HQ process to the baking industry, with specific equipment, from the point where you receive the mix right up to baking, maintaining the qualities of the product at every stage of baking, extensively simplifying the whole process. Capacity: 360 trays/h (9000

baguettes/h).

From dividing the dough to depanning, not forgetting the proofer and the oven, every single part of the HQ line has been designed to optimize each phase in baking artisan bread.

- Division, extrusion: the patented MECAFLOW process creates a layer of ideally sized dough, maintaining the strength and aeration of the mix. Pre-prepared dough pieces are cut up and placed in an opening (opening width: 55 - 80 cm). The large opening is flexible, leaving bakers freeto work with up to 25 dough pieces width wise.

- Depositing: the products are continuously deposited. The HQ trays are exclusive to MECATHERM and patented. These trays are not perforated and leave no marks on the bottom of the products. In terms of energy, the upper and lower coatings have been designed to optimize the energy reaching the products, just like the open space between the chutes allows the air blown in the oven to pass. The chutes also prevent the baguettes from spreading out more than required and give them their round shape. These chutes can also be used to improve tray filling, and therefore increase the number of baguettes placed width wise, creating up to an extra +30% space per tray compared to a peelboard.

- Proofing: the MVS (Modular Vertical System) proofer is 100% modular. Dimensions can be adjusted, from the number of cells to the number of levels. This proofer can also easily be adapted to available floor area and the type of baking support used. The system is easy to clean (plasticized chains) and maintenance is straightforward (no greasing required, easy access, automatic humidity control). Slow ventilation (< 0.5 m/s) prevents a skin forming on the surface. Proofing time is adapted to the volume of bread required, rising and behavior during baking, as well as the preferred crumb structure.

- Water scoring: guaranteeing ideal scoring by water jet, leaving a clean cut, even if the recipe is well hydrated (no dough sticking to blades,). This aspect can be configured from start to finish; users can define the number of cuts, the angle and length of the cuts, overlap between cuts and the depth of the cuts. One single piece of dough can therefore be scored at various angles.

- Baking: the FMP convection oven is designed to reinforce the effect of yeast and hearth baking and is modular (1 - 6 cells) depending on the required period of baking, or whether the products are to be baked or pre-baked, and on the format of the products baked (50 or 500 g). One or several cells can be by-passed, and several baking zones can be configured separately. Alternate blowing (from left to right, and then from right to left, for alternate levels) optimizes heat exchange, with products subjected to a low air flow. The different temperatures and steam can be controlled separately and precisely for each zone. The BBB (Bottom Bake Booster) is a MECATHERM patented solution, where the trays are preheated in few second at high temperature before entering into the oven. This system also prevents the steam from condensing and avoids any runoff along the molds and frames. Two different post-baking cold circuit options are available: either on trays or using cooling/freezing coils. If cold trays are used, a tray slicing option is available for sandwich bread.

- Depanning: the finger depanner will not deform the product. This device will also leave the position of the product unchanged, simplifying checks and product routing to the packaging area.

- Conveyor: the conveyor system is reliable and resistant, produced in stainless steel and with approved food grade materials, and equipped with gradual acceleration and deceleration functions, avoiding sudden impacts. This system is easy to maintain (standard motors, no greasing) and ergonomic.