Companies that make seasoning and coating systems for snack and bakery applications—which mostly focus on salty snacks like chips, cheese puffs, pretzels, and popcorn—report a number of trends in requests regarding features and benefits from customers of such machines during the COVID-19 pandemic of the past couple years.

These have included greater flexibility to provide more varieties of flavorings as well as new lines of business, the ability to handle spicier mixes for certain markets and more modest coatings for healthier formulations, greater levels of consistency to ensure end-purchaser satisfaction, and the automated systems that help to provide consistency, efficiency and productivity, as well as labor savings.

Heat and Control - Totally Automated Seasoning Control

Heat and Control, Hayward, CA, has been receiving requests over the past couple of years for automated solutions to keep labor costs down while increasing efficiency and productivity, and for flexibility of design so that systems can handle a variety of products, according to Tim Nanney, technical sales manager-North America.

“Now, more than ever, customers are looking for automated solutions to reduce the number of operators required to run a production line,” he says. In addition, “We have seen an increase in requests for coating systems that are able to handle a variety of products. Many requests require that the coating system be portable to allow for use on multiple lines.”

Heat and Control has worked with global manufacturing partners Ishida and CEIA to share experiences and solutions to common problems, such as balancing supply-chain requirements, improving the ability to support customers, says Brian Barr, director of sales. “We have also learned the value of partner qualification, working with our key suppliers [and] partners to navigate market challenges, prioritization, and collaborative problem resolution,” he says.

Customers have been asking for more salty snack food products that require slurry coatings mixing liquid and dry seasoning blends rather than applying them separately, some of which require additional dwell time within the coating drum to reach the desired appearance, flavor, and texture, Nanney says.

To that end, “We developed a motorized weir system that is attached to the discharge end of the drum,” he says. “The adjustable weir allows us to increase our dwell times up to 10 to 12 minutes, as required.” The weir system also “eliminates the need for additional equipment, minimizing footprint and system cost,” he adds.

Heat and Control also has released the Totally Automated Seasoning Control (TASC) complete seasoning solution, encompassing the Revolution Gate to the Ishida weigher and the AirFry System, and featuring the Spray Dynamics system that precisely meters oil usage, says Blake Svejkovsky, general manager – product handling systems. “This patented technology reduces or eliminates titration tests due to trust in and performance of the system and improved standard deviation,” he says.

The closed-loop seasoning control strategy provides instantaneous feedback to improve seasoning performance, reducing labor costs by lowering the need for offline analytical quality control tests due to its accuracy, decreasing consumer complaints, and product holds, Svejkowsky says. This also validates and automatically creates seasoning usage reports while boosting the percentage of seasoning content on the chip, he says.

PPM Technologies - FlavorWright All-in-One

The snacking business has boomed during the pandemic with people working from home, which has meant the need to be able to handle a greater variety, says Neil Anderson, vice president of business development for PPM Technologies, Newberg, OR. As manufacturers of snacks start to implement those additional varieties, the cheapest way is to maintain the base product and keep coming out with new flavors, he says.

Snack makers also have been more aggressive about crossing into one another’s turf during the pandemic, Anderson says. “Companies that traditionally have done a chip type of product, corn chip or potato chip, now are starting to do popcorn,” he says. “Guys doing popcorn are thinking about an extruded product like cheese puffs or cheese curls. We’re seeing new lines coming in from traditional and nontraditional sources.”

Healthier snacks have been part of the mix, although Anderson doesn’t think they’ve diluted the market share of more standard snacks very much, and he says the former formulations don’t impact the equipment that profoundly. “It often requires a much smaller amount of either liquid or seasoning. That can be a challenge,” he says. “It takes some reengineering of systems to provide that, which we’re pleased to do.”

PPM has been working more with snack makers in Latin America, who Anderson notes tend to have “different standards for flavorings than in the U.S. We’ve had to modify the design of our equipment to accommodate that. The put on a very high percentage of spicy types of flavorings.” Their demands have increased, as well, he notes.

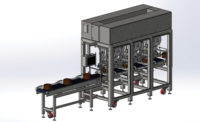

PPM has upgraded its FlavorWright system to offer the FlavorWright All-in-One, a module that incorporates an infeed conveyor, seasoning drum, seasoning applicator, and an oil spray system that work off of integrated controls via a touch-screen display, Anderson says. “It’s a plug-and-play system,” he says, adding that it can be used for all types of snacks, with variations available in the length of the drum and the size of pumps and nozzles used for liquids.

With the greater variety of types of snacks and flavorings, PPM has seen manufacturers who once might have run 5,000 pounds per hour of potato chips through one enormous drum, and then apply nothing but salt for three days, now buying an individual seasoning system for each scale, Anderson says. “And however many scales they have, they have that many flavors,” he says. “We put in an integrated system that would allow you to apply seasoning onto a certain amount of chips as they got fed onto the scale.”

“We work with a lot of the snack companies to integrate their seasoning combinations,” he says. Some might be stickier, some might be more flavor-sensitive, he adds. “We’re able to work with them to apply higher or lower rates, and in some cases modify the equipment, so that it reduces the buildup of seasoning and reduces the waste.”

Tinsley Equipment Co. - Electrostatic Seasoning and Food Coating System

Customers of Tinsley Equipment Company, College Station and Granbury, TX, are looking for greater flexibility to provide more varieties of flavorings, says Travis Rice, president and sales manager. “They’re getting into a lot of different flavors—for instance, flavored almonds, or flavored popcorn,” he says. “They want to be able to have the equipment to handle the flexibility and variety of flavorings and seasonings.”

Tinsley, which offers the Electrostatic Seasoning and Food Coating System for these purposes, has been working to create a more simplified package among the feeding, enrobing and application processes. “The set-up and installation time are much faster,” Rice says. “Mounting hardware on the supporting frame reduces the assembly time, and it becomes a process of attachment components to the mounting frames.”

Tinsley also has undertaken controller upgrades to improve the interface to the machinery. “It’s a cleaner interface between the inputs from the operators into the equipment,” he says. “Before, we had it in a few individual control boxes; now, we can combine it into a single control box.”

The technology itself, an electrostatic system for applying dry and liquid seasonings and flavorings, works the same as it has in the past, Rice says. Product is fed into the flighted enrobing drum and positively charged, while a negative charge is applied to the seasoning or coating as it’s sprayed onto the product, bonding tightly. This improves efficiency, consistency and cleanliness of working conditions, according to Tinsley.

“We can improve the coating efficiency of the snack products by using our technology in conjunction with application systems, whether dry or liquid,” he says. “We can see reduction over conventional gravity-type applications—10% to 30% is not uncommon. At the end of the month, for a facility, that can significantly reduce the cost of production.”

tna solutions - intelli-flav OMS 5.1

Customers of tna solutions, Coppell, TX, prioritize control over seasonings, according to Teri Johnson, vice president North America. “Applying an incorrect level of seasoning can have a significant impact on both input costs in terms of raw materials, and waste costs from rejected products,” she says. “Another major driver for our customers is the impact of inconsistent seasoning on customer satisfaction and, therefore, repeat purchase.”

tna has designed the intelli-flav OMS 5.1 to accurately monitor seasoning quantities, ensuring that the right amount of oil, salt or other coatings are applied via intelligent control and monitoring software to reduce waste and increase profitability, Johnson says. The on-machine seasoning system offers consistent coverage for wet and dry ingredients in a single drum.

“We developed this solution to address the growing demand from customers seeking solutions to reduce material waste at the seasoning phase,” she says. “Many traditional systems use volumetric means to apply powders, oils or slurries, which not only puts pressure on the operator to achieve consistent results but also can lead to costly waste or unhappy customers.”

The intelli-flav system uses preprogrammed recipes to apply the precise amount of seasoning needed, while also addressing additional challenges for customers, Johnson says. “Its inherently sanitary design uses smooth, food-grade stainless steel surfaces and specialized, welded joints to eliminate produce residue and micro-organism build-up, which reduces the time needed to fully sanitize the system,” she says. “This allows manufacturers to switch flavors or product runs quickly yet safely—helping them keep up with fast-moving consumer trends without wasting hours of expensive downtime.”