Lauren R. Hartman, Editor-in-Chief

Old Colony Baking Co. started 14 years ago as a marketing firm that had all of its products co-packed by an outside source. Today, the company, based in Spring Valley, Ill., in the heart of “corn country,” markets an assortment of co-branded cookies, animal crackers, brownies and other pastry bars, while its sister company, Spring Valley Baking Co., which operates out of the same location, contract-packs a collection of taste-tempting brownies, lemon bars, chocolate chip bars and coming soon, a coconut bar, with no preservatives or trans fat.

“We got back into manufacturing with the addition of Spring Valley Baking and combined offices,” relates Jeffrey Kaufman, Old Colony/Spring Valley president.

He probably has brownies in his blood, as he’s been in the brownie business for years, starting his career in 1969 with Plantation Baking, a family business, while working during his school vacations. His wife, Ann, who is chief executive officer of Old Colony and head of administration for both Spring Valley and Old Colony, also worked at Plantation as the office manager, and guided more than 20 office personnel. “I worked with my uncles Mal and Leon Kaufman and all of my training came from them,” Jeffrey Kaufman recalls. “Leon was the technical one and Mal was on the sales and administrative side. Plantation was sold in 1986 and I stayed on until 1994. My uncles were an integral part of the whole thing.”

Jeffrey and Ann Kaufman started the business after spending more than 25 years at Plantation Baking. Jeffrey Kaufman learned early on that there was never a substitution for quality. Ann Kaufman left Plantation and the pair started Old Colony Baking nearly 15 years ago, and then branched out to form Spring Valley Baking in 2008.

Together, the companies offer some 25 stock-keeping units, including theOld Colonyand co-packed products and Spring Valley’s 10-plus SKUs. The shelf-stable products include pastries and co-branded cookies, gourmet fudge brownies that can be topped with nuts, chocolate chips or Decorattes (sprinkles), chocolate chip and lemon brownie bars and animal crackers for vending, convenience store, mini-mart, grocery and foodservice channels of distribution, to name a few. Spring Valley Baking co-packs any of the products under private label and can custom-bake any size for various package configurations a customer would require, Jeffrey Kaufman says.

Distributed nationally, the cookies, which come in walnut shortbread, apple sauce oatmeal, lemon, animal crackers and assortments and are packed in 1- and 2-oz. brightly printed bags, are produced for Old Colony by Cookie Kingdom, an outside source nearby. In addition to the Old Colony brand, the cookies feature labels from licensor partners such asMusselman’s, Diamond, ReaLemonand Old Colony’s ownCarnivaltrademark.

While Jeffrey Kaufman says Old Colony can’t offer any of its “branded” items specifically for private-label distribution, it can make available various cookie products to serve various needs. “We can provide a totally finished project, including, but not limited to, formulations, packaging artwork, packaging film selection and standup displays,” he continues.

Rehabbed plant, quality image

To launch the sister company/contract-packaging business, the Kaufmans bought a formerly vacant baking facility in Spring Valley, Ill., that Jeffrey Kaufman says “had to be gutted, as it hadn’t been used in probably 15 years.”

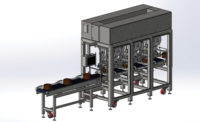

The town’s name became the contract packaging company’s name, and now, the clean, refurbished 11,000-sq.-ft. operation is home to 28 employees, is kosher- and pareve-certified and features one U-shaped production line equipped with three horizontal form/fill/seal systems that all together, generate more than 300 brownie bars a minute.

Newly built offices and a sample room where some of the product quality assurance testing is performed were added, as well as a new walk-in cooler for storing ingredients such as nuts, chocolate chips and fresh egg whites. Also, new plumbing, electrical systems and water filtration were installed. The production facility has a small storage warehouse and an engineer’s quarters, but it’s still compact. “It was difficult to decide where to put equipment and other things because of the limited space,” he adds. “So we warehouse our packaging materials off-site, and bring them and our raw materials in on a just-in-time [JIT] basis.”

Despite the coziness, things really hum on the brownie line. Production is passionate, organized, dynamic and upbeat. Demand requires that the plant generate as much as 70,000-80,000 lb. of product each week. That’s about 15,000-18,000 lb. of dough a day.

“Brownies are Spring Valley’s forte and quality is our image,” Jeffrey Kaufman says emphatically. “That’s a carry-over from my days at Plantation Baking. Quality cocoa, enriched flour, pure chocolate chips and fresh eggs are a main reason that we can provide a long shelf life. They need no refrigeration and no preservatives.”

The gourmet fudge brownies are quite popular and the Kaufmans consider brownies to be the top seller. Depending on orders, which can vary each week, Spring Valley’s contact-packing facility operates three to five days a week, and has the ability to run multiple shifts or 24 hours if necessary, Jeffrey Kaufman says. “Our capacity isn’t an issue. We maintain a bake-to-order philosophy and ask for a two-week leadtime, which gives us time to schedule, bake and ship so the customer gets the freshest product available.”

Reinforcing the bakery’s commitment to quality, the staff frequently conducts quality control inspections and there is a metal detector on the line. Part of the process is to take moisture readings of the product each hour as well as several visual checks. “But in our business, there’s nothing like a visual check and a taste,” says Jeffrey Kaufman. “We do a full QC check every hour.”

The quality control checks also involve monitoring dough deposit heights, conducting moisture readings, inspecting packaging film codes and shipping case codes and checking packaging seal integrity and package weights, the latter of which are checked every half hour.

“We’re already in step with the food safety regulations, but that’s old training for me,” Jeffrey Kaufman says. “What I know was taught to me by my uncles. They instilled things like that in me. There was never a substitute for quality, and sanitation was always first and foremost.”

Sticking with what they know

How does a baking operation like this get started in the middle of one of the worst economic situations this country’s had in years? “We had to weather the storm,” says Ann Kaufman. “It’s a challenge. Yes, we started up at the worst point in the economy. It is hard to keep a hold on costs.”

It’s a tough business, Jeffrey Kaufman adds. “We raised our prices one time, which was at the beginning of this year because commodity prices were increasing so quickly and we work on very thin margins. So where can company like ours really help itself? Here at the facility, keeping watch on weights, scrap and by making sure our yields are dead-on.”

As far as trends are concerned, “we don’t pay that much attention to those comings and goings,” he adds. “When people want a snack, they want their snack, not an ‘almost’ snack. But we really don’t react to many trends because our focus is here at the plant, and with the product at hand. I do think variety is the spice of life, however, and [I] hope independent manufacturers and their abilities to react quickly to customer needs come back into the market.”

Ann Kaufman agrees: “For us, doing what we do best and doing what works, without trying to reach too far is important. The trends come and go, but we stay with what we have-the tried and true.”

New developments

One of Spring Valley and Old Colony’s latest endeavors was to revise the graphics on the polypropylene film wraps for the primary brownie packaging with a fresh, more contemporary look that incorporates bright colors. “Along with the new packaging, we have also ‘tweaked’ the browning formula a bit and no longer use high-fructose corn syrup,” Jeffrey Kaufman notes. “The film wrap helps us provide the brownies with a 120-day shelf life. The brownies are shelf-stable. We also made the brownies darker and richer,” states the company’s website. “The new product in its new package is now in distribution.”

Also, the companies have a new coconut bar in the works. “We think coconut is making resurgence,” Jeffrey Kaufman smiles, with his eyes twinkling. He’s also very enthused about another project; Old Colony is coming out with a grocery store-sized (5-oz.) bag for the branded cookies. “We think the time is right for a larger bag size for the cookies. And very soon, we’re going to add an automatic topping applicator for the brownie line,” he points out, excitedly. “That will eliminate some labor and provide a uniform coverage of toppings on the brownies. We also hope to someday streamline the bulk handling of the raw materials and get some bulk handling equipment, but we like hand-feeding the brownies [on parts of the line] because brownies are a very delicate item and not all automatic equipment is gentle enough.”

The companies are also prepared for the recently implemented Food Safety Modernization Act as they keep the necessary records to track their products, Jeffrey Kaufman says. “We make an incoming receiving report on all raw materials and packaging materials-and we check the cleanliness of the truck that they come on. We also note all of the lot codes, and everything is dated when it comes into our facility. All of the lot codes of the ingredients are listed on a report, and bakers include lot codes on their material logs, which all tie the information together for our recall procedure.”

The two major changes Jeffrey Kaufman sees in his 30-plus years in the baking business are the differences in shortening and sugar that are now used. “At Plantation Baking, we used hydrogenated shortening. Now, we make the same high-quality product but without hydrogenated shortening. The other thing is, we don’t use high-fructose corn syrup. Invert sugar is more costly, but so are so many of the other commodities.”

Even though Spring Valley is new and just getting on its feet, it’s a startup, but not really a startup, he says. “Based on all of my experience, I’ve grown up with this process, so we have an edge.”

Whether it’s looking at automating more of its processes, developing a new, trend-setting brownie, or diving head-first into a new business, the Kaufmans and their staff happily seem glad to be on-the-go, enjoying their tasks and eating brownies all the while.